A holographic photopolymer based on the click reaction of thiol olefins

A photopolymer and olefin click technology, which is applied in the field of polymer materials, can solve the problems of long gelation time, high processing cost, and low diffraction efficiency of holographic photopolymers, and achieve accelerated gelation and phase separation, and optimized phase High separation and diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

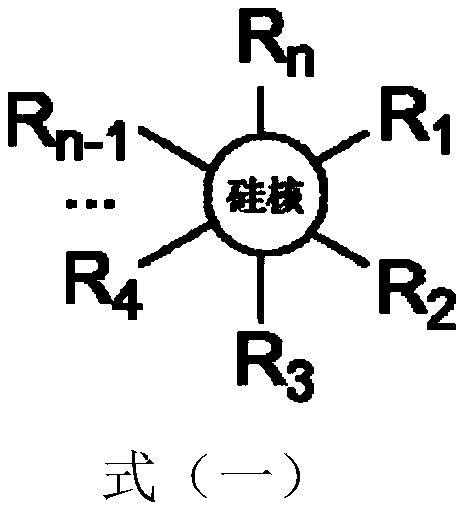

[0051] A holographic photopolymer based on thiol olefin click reaction, including 67.9% photopolymerizable monomer, 0.1wt.% photosensitizer, 2wt.% co-initiator, 30wt.% liquid crystal and 0.5wt.% thermal polymerization inhibitor.

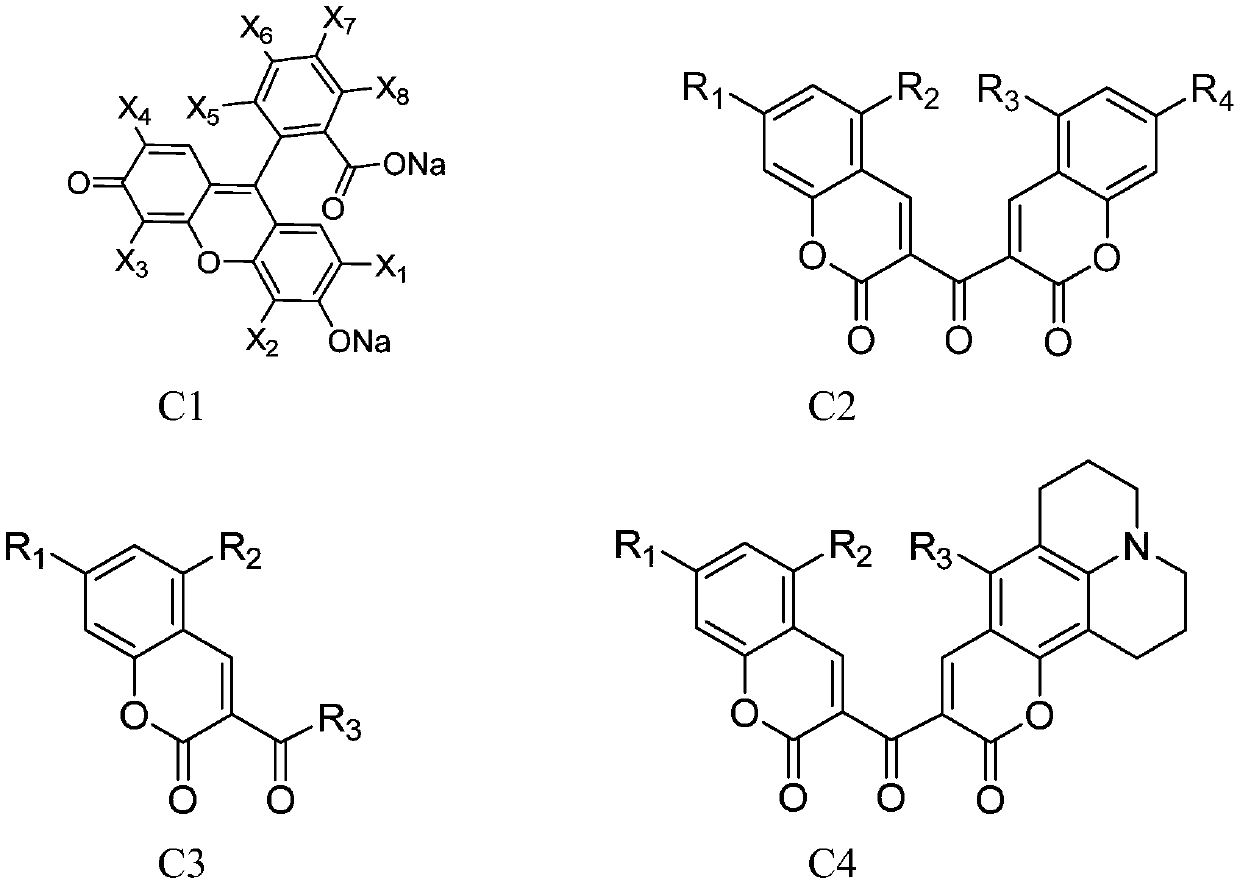

[0052] The photopolymerizable monomer is based on SiO 2 Be the thiol monomer (structure shown in formula (1), and n=4, R 1 =R 2 =R 3 =R 4 =SH), ethylene glycol bis(3-mercaptopropionate) and pentaerythritol tetraacrylate, hyperbranched acrylate 6361-100 according to the molar ratio of 1:2:1:1 mixture, the mole percentage of silicon-based monomer 20%. The photosensitizer is C1, and X 1 =X 2 =X 3 =X 4 =I,X 5 =X 6 =X 7 =X 8 =Cl, the co-initiator is a mixture of triethanolamine, acetylphenylglycine and 3-bromophenylglycine in a molar ratio of 2:2:3, wherein the mass ratio of photosensitizer to co-initiator is 1:20. The thermal polymerization inhibitor is tris(N-nitroso-N-phenylhydroxylamine) aluminum salt.

[0053] The above components were...

Embodiment 2

[0055] A holographic photopolymer based on thiol olefin click reaction, including 66.3wt.% photopolymerizable monomer, 0.6wt.% photosensitizer, 3wt.% co-initiator, 30wt.% liquid crystal and 0.1wt .% thermal polymerization inhibitor.

[0056] The photopolymerizable monomer is based on SiO 1.5 Be the thiol monomer of nucleus (structure is shown in formula (1), and n=8, R 1 =R 2 =R 3 =R 4 =R 5 =R 6 =R 7 =R 8 =C 3 h 7 SH), pentaerythritol tetrakis (3-mercaptopropionate) and triallyl isocyanurate in a molar ratio of 3:2:4, and the molar percentage of the silicon-based monomer is 33.3%. The photosensitizer is a mixture of C2 and C4 in a molar ratio of 1:1, and R 1 =R 4 =N(C 2 h 5 ) 2 , R 2 =R 3 =H, the co-initiator is a mixture of N-phenylglycine and N-ethylmaleimide in a molar ratio of 1:2, wherein the mass ratio of photosensitizer to co-initiator is 1:5. The thermal polymerization inhibitor is tris(N-nitroso-N-phenylhydroxylamine) aluminum salt.

[0057] The abo...

Embodiment 3

[0064] A holographic photopolymer based on thiol olefin click reaction, including 67.8wt.% photopolymerizable monomer, 2wt.% photosensitizer, 0.1wt.% co-initiator, 30wt.% liquid crystal and 0.1wt .% thermal polymerization inhibitor.

[0065] The photopolymerizable monomer is a thiol monomer with Si as the nucleus (the structure is shown in formula (1), and n=4, R 1 =R 2 =C 5 h 11 , R 3 =R 4 =C 2 h 4 SH), trimethylolpropane tris (3-mercaptopropionate), pentaerythritol triacrylate, and pentaerythritol triallyl ether in a molar ratio of 3:2:2:2, the molar percentage of silicon-based monomers was 33.3%. The photosensitizer is a mixture of C4 and C5 in a molar ratio of 1:1, and R 1 = Thienyl, R 2 =R 3 =H, the co-initiator is N,N,N-triethylamine, N-methylmaleimide and 2,4,6-tris(trichloromethyl)-1,3,5- The triazine is a mixture with a molar ratio of 1:2:3, wherein the mass ratio of the photosensitizer to the co-initiator is 20:1. The thermal polymerization inhibitor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com