Tylosin degrading bacterium and application thereof

A technology of tylosin and degrading bacteria, which is applied in the direction of bacteria, water/sludge/sewage treatment, biochemical equipment and methods, etc., and can solve the problems of tylosin environmental residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The collection of embodiment 1 bacterial strain

[0017] Bacteria sample collection and processing

[0018] Collect the soil, weigh 5g of the soil, add it to a Erlenmeyer flask filled with 95mL of sterilized distilled water (250mL, containing glass beads), shake it on a constant temperature shaker at 30°C, 200r / min for 30min, take it out and let it stand still;

[0019] Strain Isolation

[0020] Take 100uL of soil extract, spread it on the beef extract peptone solid medium plate, and culture it under the condition of 30°C in shade for 2 days. The composition of beef extract-peptone solid medium is: 3g beef extract, 5g peptone, 5g sodium chloride, 18g agar, distilled water to 1000mL, adjust pH to 7.0-7.2 with 1mol / L sodium hydroxide, and then sterilize.

[0021] Strain purification

[0022] Take the single colony isolated on the plate, streak it on the beef extract peptone solid medium plate, further separate and purify; this step can be repeated 2 to 3 times until a ...

Embodiment 2

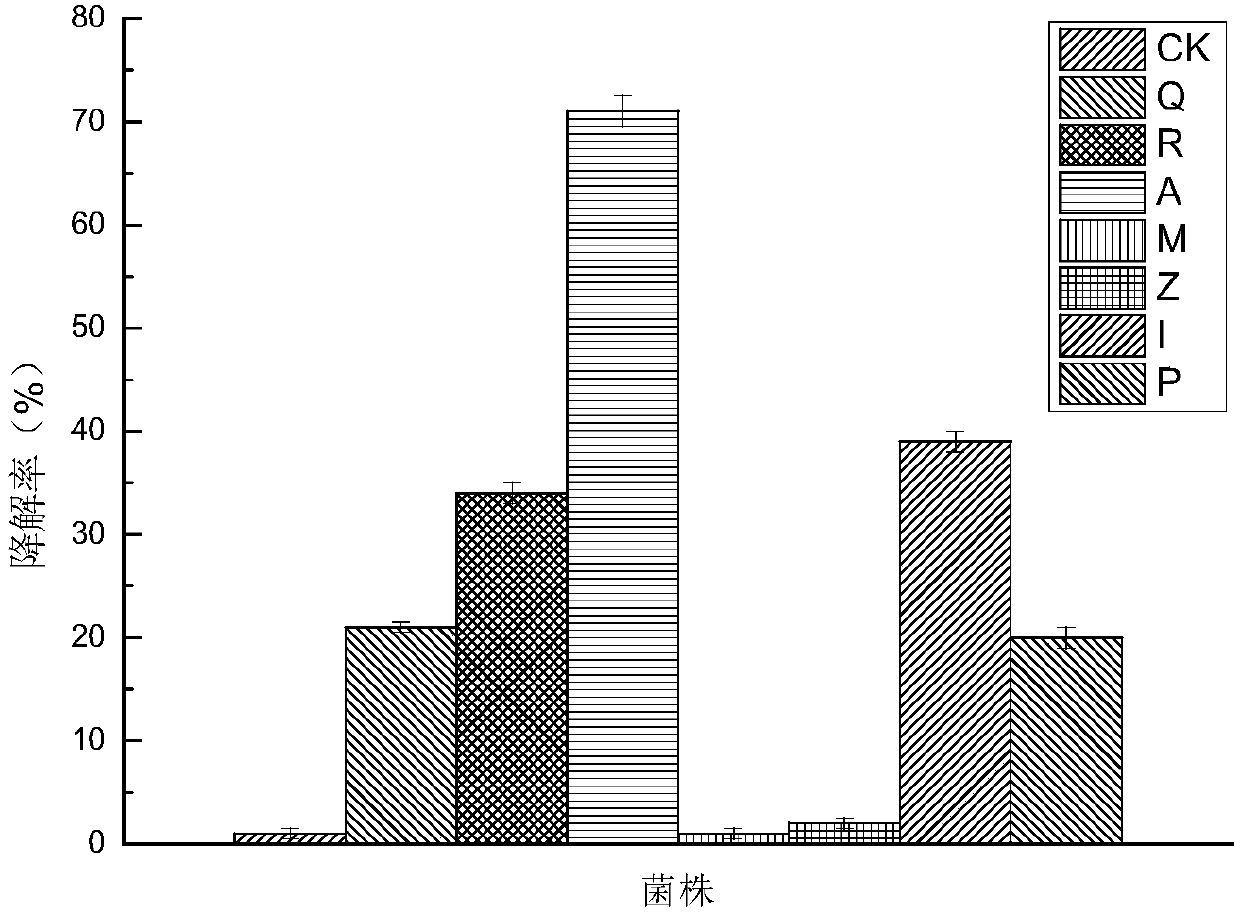

[0042] Example 2 Degradation Efficiency Determination of Tylosin Degrading Strains

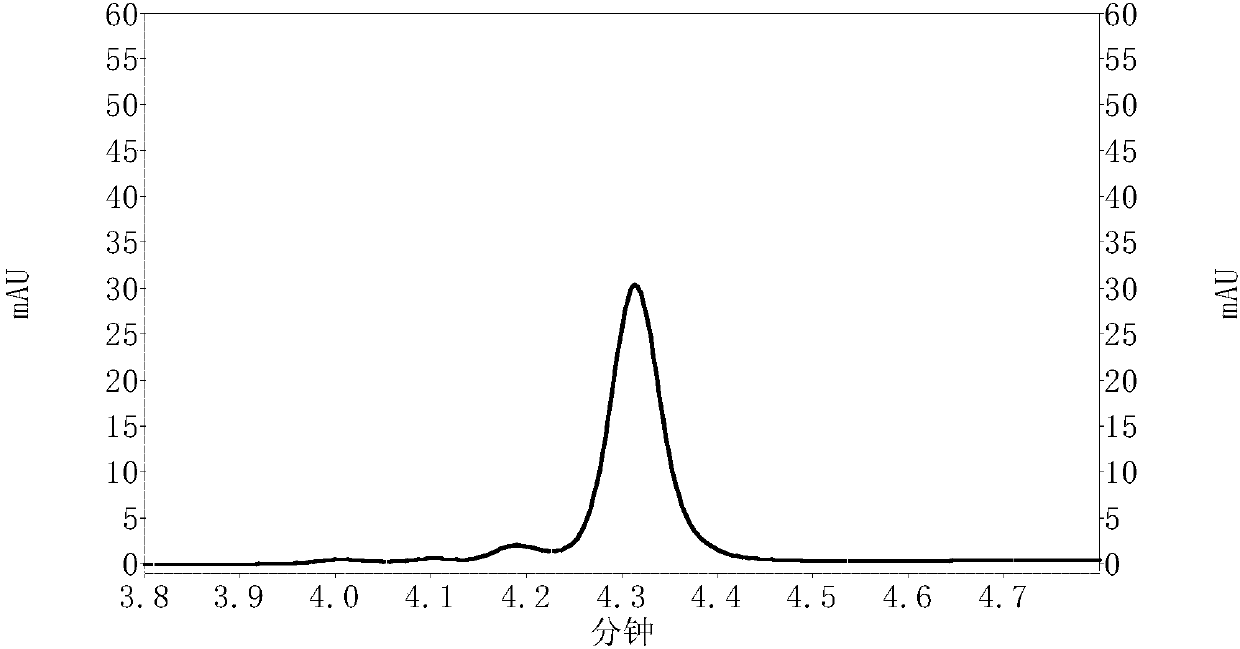

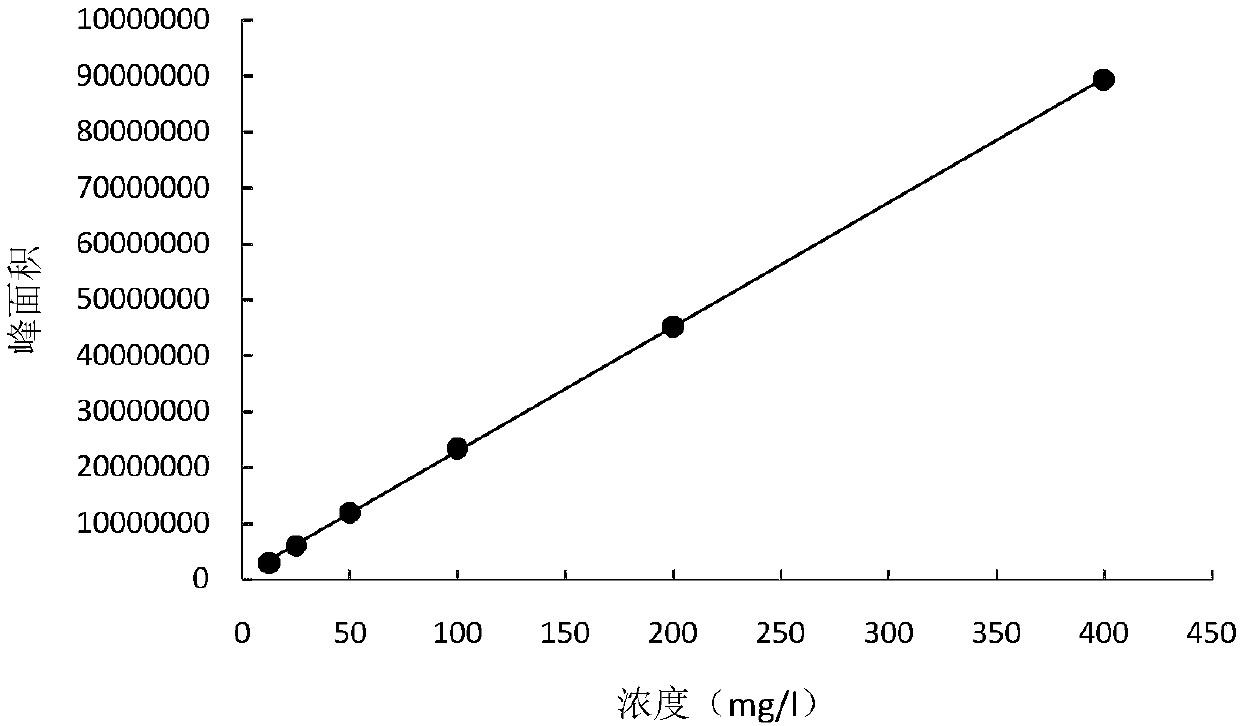

[0043] Add 100 mg / L tylosin to the inorganic salt liquid medium, shake well, inoculate a single colony, and place it at 30°C, 150r / min, and culture in shading. Chromatographic conditions: Sunfire C18 chromatographic column (150mm×4.6mm, 3.5um, Waters, USA); mobile phase is 0.01% formic acid aqueous solution (A) and acetonitrile (B); flow rate is 1.0mL / min; column temperature is 40°C; The injection volume is 10uL; the detection wavelength is 274nm. Elution program: 0~6min, 80%~0%A, 20%~100%B; 6~7min, 0%~80%A, 100%~20%B; 7~10min, 80%A, 20% b. Take 1 mL of the liquid to be tested, add 5 mL of methanol, shake well, centrifuge at 10,000 r / min for 15 min, take the supernatant, filter it with a 0.22 μm syringe filter to obtain the filtrate, and then measure it with a high-performance liquid chromatograph, such as image 3 , according to the linear regression equation to calculate the degradation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com