A kind of graphene-based oil-water separation foam material and its preparation method and application

A foam material and olefin-based oil technology, applied in the field of graphene-based oil-water separation foam material and its preparation, can solve the problems of complex operation, low efficiency, secondary pollution, etc., achieve high recovery efficiency, reduce manufacturing costs, and achieve continuous The effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of a graphene-based oil-water separation foam material, the specific steps are as follows:

[0065] 1) Soak melamine foam with a size of 3cm×3cm×3cm in a graphene oxide aqueous solution with a concentration of 0.5mg / mL for 1 hour, take it out, and dry it in an oven at 60°C for 5 hours;

[0066] 2) Soak the material obtained in step 1) in a n-hexane solution with a volume fraction of 0.1% methyltrichlorosilane for 2 minutes, take it out and dry it at 35 degrees Celsius for 1 hour to obtain a graphene-based oil-water separation foam material.

[0067] The above-mentioned graphene-based oil-water separation foam material was characterized by scanning electron microscopy, X-ray diffraction, X-ray photoelectron spectroscopy, and Raman spectroscopy, etc., as shown in Figures 1-4.

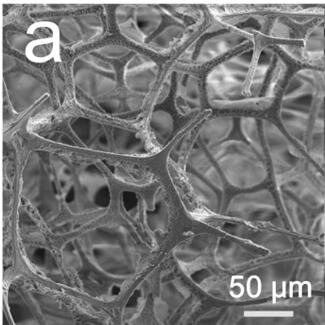

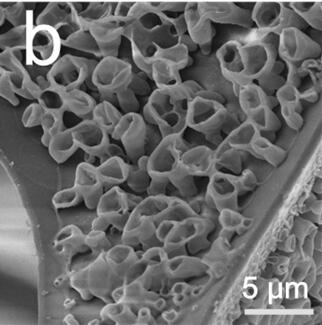

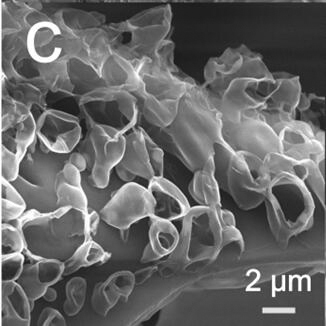

[0068] like Figure 1a , Figure 1b , Figure 1c and Figure 1d As shown in the scanning electron microscope image, the foam material skeleton prepared in this embodiment grow...

Embodiment 2

[0074] A preparation method of a graphene-based oil-water separation foam material, the specific steps are as follows:

[0075] 1) Soak a polyurethane foam with a size of 3cm×3cm×3cm in a graphene oxide aqueous solution with a concentration of 1mg / mL for 1 hour, take it out and squeeze it twice to remove most of the moisture absorbed in the foam. Oven drying for 5h;

[0076] 2) Soak the material obtained in step 1) in an acetone solution with a volume fraction of 0.2% methyltrichlorosilane for 2 minutes, take it out and dry it at 25°C for 1 hour to obtain a graphene-based oil-water separation foam material.

[0077] The contact angle of the graphene-based oil-water separation foam material is 148 degrees; its adsorption capacity to different types of oil products, such as Image 6 shown.

Embodiment 3

[0079] A preparation method of a graphene-based oil-water separation foam material, the specific steps are as follows:

[0080] (1) Soak polyvinyl alcohol foam with a size of 3cm×3cm×3cm in a graphene oxide aqueous solution with a concentration of 0.1mg / mL for 1 hour, take it out, and dry it in an oven at 50°C for 8 hours;

[0081] (2) Soak the material obtained in step (1) in n-hexane solution of octadecyltrichlorosilane with a volume fraction of 0.1% for 10 minutes, take it out and dry it at 25°C for 3 hours to obtain graphene-based oil-water separation foam material.

[0082] The contact angle of the graphene-based oil-water separation foam material is 128 degrees; its adsorption capacity for different types of oil products, such as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com