Plum vinegar for reducing blood pressure and processing method thereof

A processing method and technology for lowering blood pressure, applied in the field of fruit vinegar, can solve problems such as poor quality of fruit vinegar, and achieve the effects of solving poor quality, ensuring edibility and flavor, and increasing the content of selenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

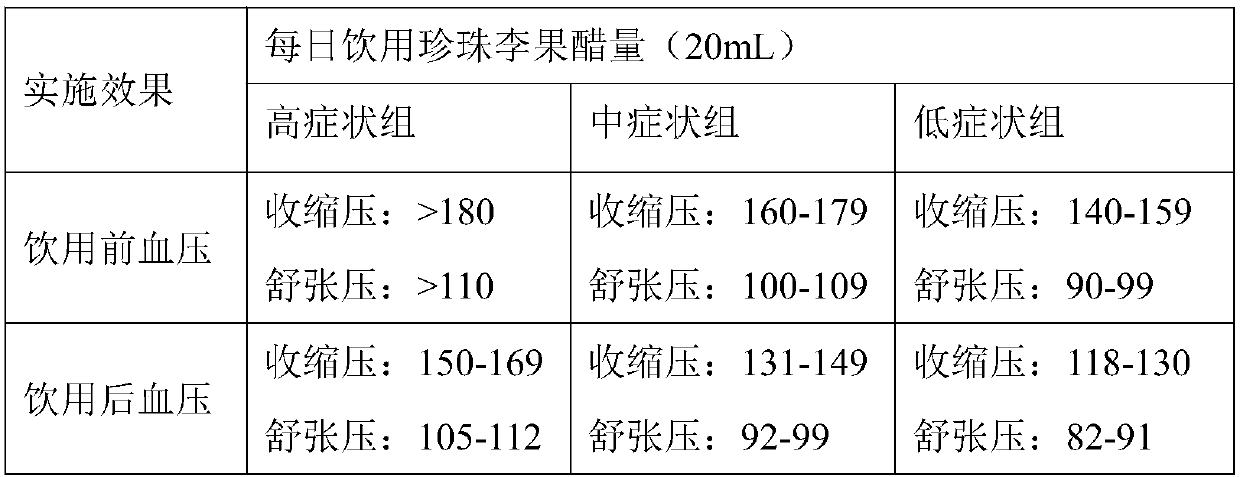

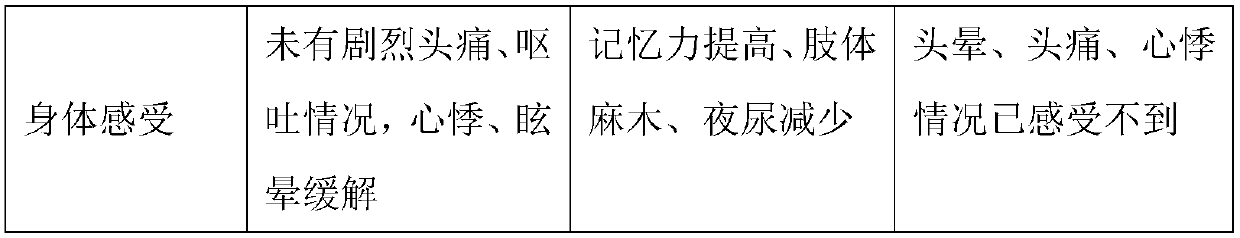

Examples

Embodiment 1

[0035] (1) Put the 8 mature pearl plums after picking in the ripening warehouse, keep the temperature at 25°C, the relative humidity is 90%, the ethylene concentration is 20ppm, and the carbon dioxide content is 0.8%, so as to maintain the uniform flow of the gas in the warehouse and accelerate the ripening. Cooked for 24 hours;

[0036] (2) Squeeze the juice into pearl plum pulp after ripe pearl plums are depitted;

[0037] (3) Add pectinase with a mass percentage content of 1% to the pearl plum pulp at 35° C., and perform enzymatic hydrolysis for 3 hours;

[0038] (4) Mix the crushed black rice flour with skin, black fungus powder, protein sugar (commercially available) and enzymolyzed pearl plum pulp in a ratio of 3:2:1:94 to form a mixed pearl plum pulp ; adjust the soluble solid content of the mixed pearl plum pulp to 20% with white sugar;

[0039] (5) Heat and sterilize the blended pearl plum pulp in a water bath at 85°C for 30 minutes, then lower the temperature to 30...

Embodiment 2

[0046] (1) Place the 8 mature Pearl Plums after picking in the ripening warehouse, keep the temperature at 28°C, the relative humidity is 93%, the ethylene concentration is 30ppm, and the carbon dioxide content is 1%, so as to maintain the uniform flow of the gas in the warehouse and accelerate the ripening. Finished within 20 hours;

[0047] (2) Squeeze the juice into pearl plum pulp after ripe pearl plums are depitted;

[0048] (3) Add pectinase with a mass percentage of 2% to the pearl plum pulp at 40°C, and perform enzymatic hydrolysis for 2.5 hours;

[0049] (4) Mix the pulverized black rice flour with skin, black fungus powder, protein sugar and enzymolyzed pearl plum pulp in a ratio of 4:3:1:92 to form a mixed pearl plum pulp; mix with white sugar The soluble solids content of pearl plum pulp is adjusted to 25%;

[0050] (5) Heat and sterilize the blended pearl plum pulp in a water bath at 95°C for 15 minutes, then lower the temperature to 35°C and add 0.4% of the ble...

Embodiment 3

[0057] (1) Place the 8 mature Pearl Plums after picking in the ripening warehouse, keep the temperature at 30°C, the relative humidity is 93%, the ethylene concentration is 25ppm, and the carbon dioxide content is 1%, so as to maintain the uniform flow of the gas in the warehouse and accelerate the ripening. Finished within 20 hours;

[0058] (2) Squeeze the juice into pearl plum pulp after ripe pearl plums are depitted;

[0059] (3) Add pectinase with a mass percentage content of 2% to the pearl plum pulp at 45°C, and perform enzymatic hydrolysis for 2.0 hours;

[0060] (4) Mix the pulverized black rice flour with skin, black fungus powder, protein sugar and enzymolyzed pearl plum pulp in a ratio of 4:3:2:91 to form a mixed pearl plum pulp; mix with white sugar The soluble solids content of pearl plum pulp is adjusted to 30%;

[0061] (5) Heat and sterilize the blended pearl plum pulp in a water bath at 100°C for 10 minutes, then lower the temperature to 38°C and add 0.5% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com