Photosensitive resin composition, polyimide production method, and semiconductor device

A technology of photosensitive resin and polyimide precursor, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as difficult to meet, and achieve the effect that circuit breakage is not easy to occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

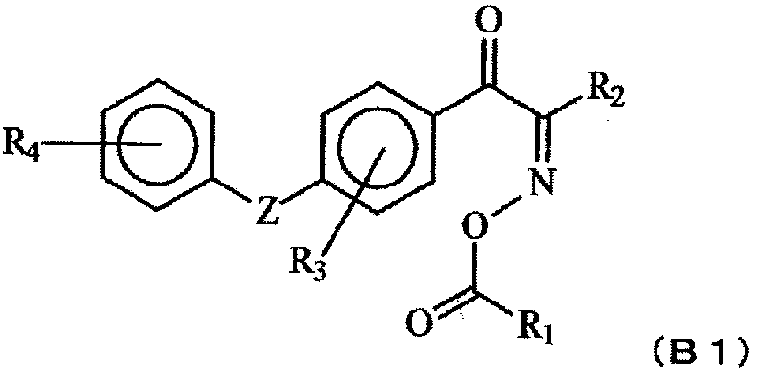

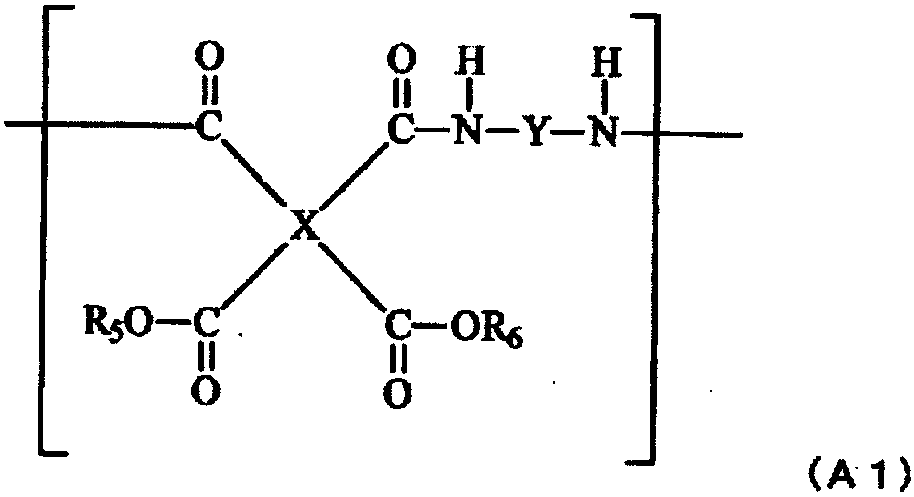

Method used

Image

Examples

preparation example Construction

[0125] (Preparation of acid / ester body)

[0126] In the present invention, as the tetracarboxylic dianhydride containing the tetravalent organic group X suitably used for the preparation of the polyimide precursor of the ester bond type, the acid dianhydride having the structure represented by the above-mentioned general formula (30) Anhydrides, for example, pyromellitic anhydride, diphenyl ether-3,3',4,4'-tetracarboxylic dianhydride, benzophenone-3,3',4,4'-tetracarboxylic Carboxylic acid dianhydride, biphenyl-3,3',4,4'-tetracarboxylic dianhydride, diphenylsulfone-3,3',4,4'-tetracarboxylic dianhydride, diphenylmethane- 3,3',4,4'-tetracarboxylic dianhydride, 2,2-bis(3,4-phthalic anhydride)propane, 2,2-bis(3,4-phthalic anhydride) -1,1,1,3,3,3-hexafluoropropane, etc. Preferable examples include pyromellitic anhydride, diphenyl ether-3,3',4,4'-tetracarboxylic dianhydride, biphenyl-3,3',4,4'-tetracarboxylic dianhydride, and the like. Preferable examples include pyromellitic anhy...

Embodiment

[0251] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these. The physical properties of the photosensitive resin compositions in Examples, Comparative Examples, and Production Examples were measured and evaluated by the following methods.

[0252] (1) Weight average molecular weight

[0253] The weight average molecular weight (Mw) of each polyamic acid ester synthesize|combined by the method mentioned later is measured by standard polystyrene conversion by gel permeation chromatography (GPC). The analysis conditions of GPC are described below.

[0254] Column: Shodex 805M / 806M series manufactured by Showa Denko Co., Ltd.

[0255] Standard monodisperse polystyrene: Shodex STANDARD SM-105 manufactured by Showa Denko Co., Ltd.

[0256] Eluent: N-methyl-2-pyrrolidone 40°C

[0257] Flow rate: 1.0ml / min

[0258] Detector: Shodex RI-930 made by Showa Denko

[0259] (2) Fabrication of solidified relief patterns on Cu

...

manufacture example 1

[0270] (synthesis of (A) photosensitive polyimide precursor (polymer A-1))

[0271] Put 155.1 g of 4,4'-oxydiphthalic anhydride (ODPA) into a 2-liter detachable flask, add 134.0 g of 2-hydroxyethyl methacrylate (HEMA) and γ-butylene Esters 400ml. While stirring at room temperature, 79.1 g of pyridine was added to obtain a reaction mixture. After the heat generation due to the reaction ended, it was cooled to room temperature and then left still for 16 hours.

[0272] Next, a solution obtained by dissolving 206.3 g of dicyclohexylcarbodiimide (DCC) in 180 ml of γ-butyrolactone was added to the reaction mixture over 40 minutes while stirring under ice-cooling. Next, a suspension obtained by suspending 93.0 g of 4,4'-diaminodiphenyl ether (DADPE) in 350 ml of γ-butyrolactone was added over 60 minutes while stirring. Furthermore, after stirring at room temperature for 2 hours, 30 ml of ethanol was added and stirred for 1 hour. Then, 400 ml of γ-butyrolactone was added. Preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com