Graphene ultraviolet UV photo-curing white coating and preparation method thereof

A UV and light curing technology, applied in the field of paint and paint, can solve the problems of poor stain resistance, high cost, and environmental pollution of scratch-resistant paint films, and achieve the effect of improving anti-corrosion effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

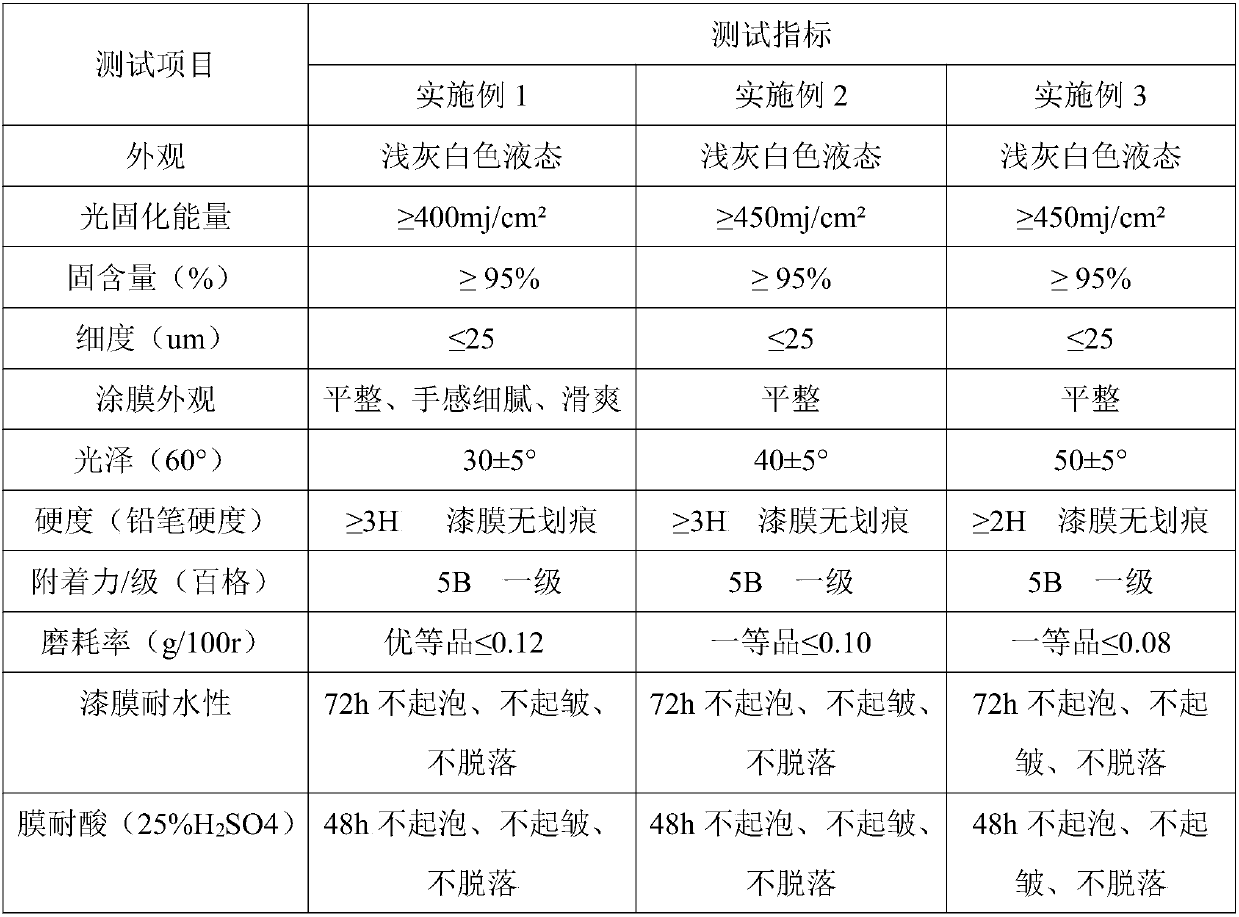

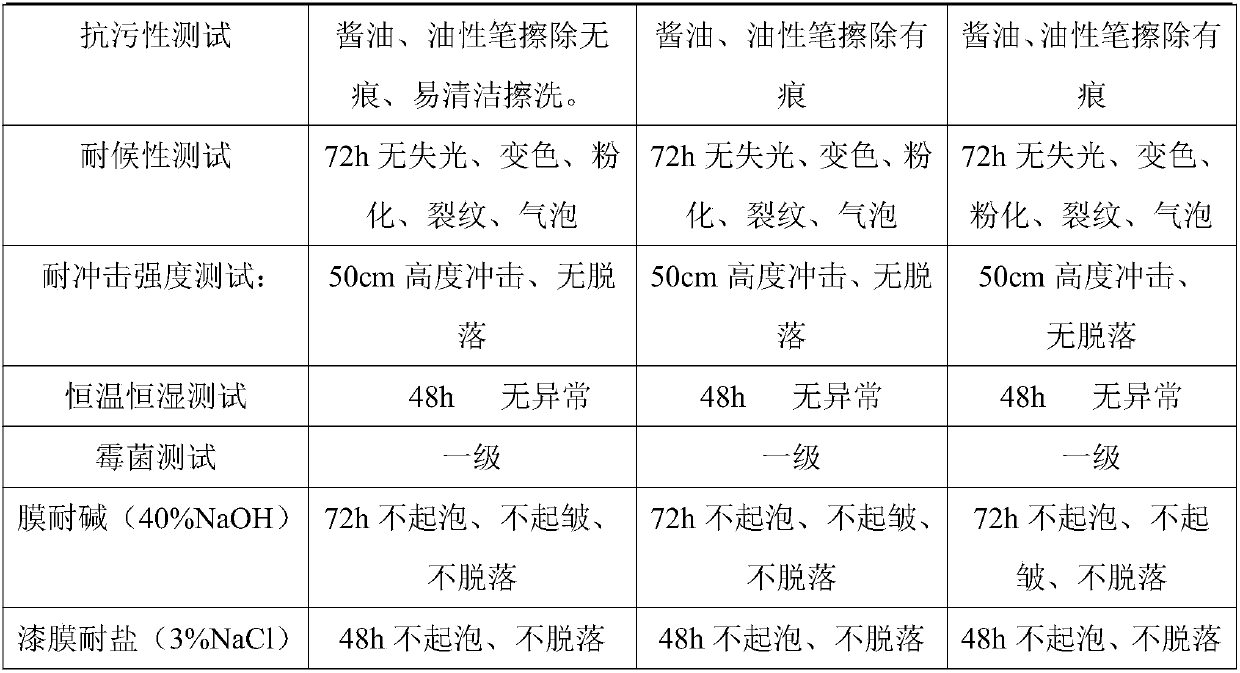

Examples

Embodiment 1

[0028] Prepare graphene ultraviolet UV photocurable white paint of the present invention, concrete steps are:

[0029] (1) Weigh each raw material component: UV curable silicone resin 20kg, UV curable bisphenol A epoxy acrylate resin 10kg, ethylene glycol dimethacrylate 5kg, tripropylene glycol diacrylate 5kg, 2,4 , 5kg of 6-trimethylbenzoyldiphenylphosphine oxide, 3kg of 1-hydroxy-cyclohexylbenzophenone, 5kg of graphene oxide powder, 1kg of wetting and dispersing agent, 1kg of ultraviolet light absorber, 10kg of aluminum dioxide , Titanium dioxide 10kg, anti-mold and antibacterial agent 1kg, fluorine additive 1kg, hydroxyl-terminated polybutadiene 1kg;

[0030] (2) Add 1-hydroxyalkylhexylbenzophenone, 2,4,6-trimethylbenzoyl diphenylphosphine oxide, tripropylene glycol diacrylate and ethylene glycol dimethacrylate to the reaction In the container, heat up to 60°C, and stir at a constant temperature of 1000rpm for 20min to obtain a mixed solution A;

[0031] (3) When the temp...

Embodiment 2

[0034]Prepare graphene ultraviolet UV photocurable white paint of the present invention, concrete steps are:

[0035] (1) UV curing silicone resin 30kg, UV curing bisphenol A epoxy acrylate resin 20kg, ethylene glycol dimethacrylate 10kg, tripropylene glycol diacrylate 10kg, 2,4,6-trimethylbenzene Formyl diphenylphosphine oxide 10kg, 1-hydroxy-cyclohexyl benzophenone 5kg, graphene oxide powder 10kg, wetting and dispersing agent 3kg, ultraviolet light absorber 3kg, aluminum dioxide 20kg, titanium dioxide 20kg, anti-mold Antibacterial agent 3kg, fluorine additive 3kg, polycarboxylic acid 3kg;

[0036] (2) Add 1-hydroxyalkylhexylbenzophenone, 2,4,6-trimethylbenzoyl diphenylphosphine oxide, tripropylene glycol diacrylate and ethylene glycol dimethacrylate to the reaction In the container, the temperature was raised to 60°C, and the mixture was stirred at a constant temperature of 1000rpm for 20min to obtain the mixed solution A;

[0037] (3) After the temperature of the mixed li...

Embodiment 3

[0040] Prepare graphene ultraviolet UV photocurable white paint of the present invention, concrete steps are:

[0041] (1) UV curing silicone resin 25kg, UV curing bisphenol A epoxy acrylate resin 15kg, ethylene glycol dimethacrylate 8kg, tripropylene glycol diacrylate 8kg, 2,4,6-trimethylbenzene Formyl diphenylphosphine oxide 8kg, 1-hydroxy-cyclohexyl benzophenone 4kg, graphene oxide powder 8kg, wetting and dispersing agent 2kg, ultraviolet light absorber 2kg, aluminum dioxide 15kg, titanium dioxide 15kg, anti-mold Antibacterial agent 2kg, fluorine additive 2kg, hydroxyl-terminated polybutadiene and polycarboxylic acid 1:1 mixture by weight 2kg;

[0042] (2) Add 1-hydroxyalkylhexylbenzophenone, 2,4,6-trimethylbenzoyl diphenylphosphine oxide, tripropylene glycol diacrylate and ethylene glycol dimethacrylate to the reaction In the container, the temperature was raised to 60°C, and the mixture was stirred at a constant temperature of 1000rpm for 20min to obtain the mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com