Livestock vitamin complex micro-capsule and preparation method thereof

A technology of compound vitamins and vitamins, which is applied in animal husbandry, additional food elements, molding or processing of animal feed, etc. It can solve the problem of unsatisfactory sustained release effect of compound vitamin microcapsules, poor uniformity of compound vitamin powder, and antagonism between ingredients To achieve the effect of improving anti-oxidation and anti-moisture absorption performance, reasonable proportion, and conducive to balanced absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The poultry compound vitamin microcapsules include vitamin A 25 million IU, vitamin D 3 10 million IU, Vitamin E 200g, Vitamin K 3 10g, vitamin B 1 10g, vitamin B 2 25g, vitamin B 6 20g, vitamin B 12 100mg, Niacinamide 100g, D-Calcium Pantothenate 50g, Folic Acid 5g, Biotin 1g, Soluble Starch 10g, Stearic Acid 100g, Arabic Gelatin 5g, Polyoxyethylene Castor Oil 50g, BHT 0.01g, BHA 0.02g, Sodium Benzoate 2g .

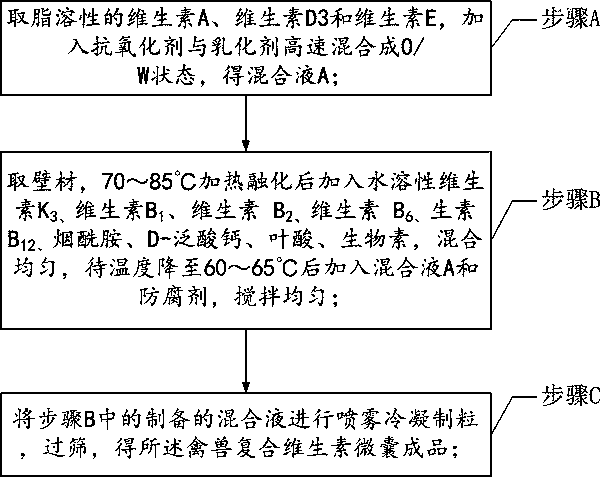

[0043] The preparation method of the multivitamin microcapsules of poultry and livestock comprises the following steps:

[0044] S001. Accurately weigh 25 million IU of fat-soluble vitamin A and vitamin D 3 10 million IU, vitamin E 200g, add BHT 0.01g, BHA 0.02g and polyoxyethylene castor oil 50g and mix at high speed for 20 minutes to get mixture A;

[0045] S002, take stearic acid 100g, Arabic gelatin 5g, heat and melt at 80 ℃, add water-soluble vitamin vitamin K 3 10g, vitamin B 1 10g, vitamin B 2 25g, vitamin B 6 20g, vitamin B 12 100mg...

Embodiment 2

[0048] The poultry compound vitamin microcapsules include vitamin A 25 million IU, vitamin D 3 10 million IU, Vitamin E 200g, Vitamin K 3 10g, vitamin B 1 10g, vitamin B 2 25g, vitamin B 6 20g, vitamin B 12 100mg, Nicotinamide 100g, D-Calcium Pantothenate 50g, Folic Acid 5g, Biotin 1g, BHT 0.01g, BHA 0.02g, Tween 20 6g, Tween 80 50g, Glyceryl Monostearate 100g, Insect Wax 8g, Silicon oxide 10g, sodium benzoate 2g.

[0049] The preparation method of the multivitamin microcapsules of poultry and livestock comprises the following steps:

[0050] S001. Accurately weigh 25 million IU of fat-soluble vitamin A and vitamin D 3 10 million IU, vitamin E 200g, BHT 0.01g, BHA 0.02g, Tween 80 50g and Tween 20 6g were mixed at high speed for 20 minutes to obtain a mixture A.

[0051] S002, take 100g of glyceryl monostearate and 8g of insect wax, heat and melt at 80°C, add water-soluble vitamin K 3 10g, vitamin B 1 10g, vitamin B 2 25g, vitamin B 6 20g, vitamin B 12 100mg ...

Embodiment 3

[0054] The poultry compound vitamin microcapsules include vitamin A 56 million IU, vitamin D 3 8 million IU, Vitamin E 280g, Vitamin K 3 6g, vitamin B 1 8g, vitamin B 2 50g, vitamin B 6 18g, vitamin B 12 150mg, Niacinamide 150g, D-Calcium Pantothenate 45g, Folic Acid 6g, Biotin 0.6g, Propyl Gallate 0.1g, BHT 0.15g, Tween 60 40g, Tween 80 50g, Stearic Acid 50g, Hydrogenated Soybean Oil 80g , calcium carbonate 100g, sodium benzoate 4g.

[0055] The preparation method of the multivitamin microcapsules of poultry and livestock comprises the following steps:

[0056] S001. Accurately weigh 56 million IU of fat-soluble vitamin A and vitamin D 3 8 million IU, vitamin E 280g, add propyl gallate 0.1g, BHT 0.15g, Tween 80 50g and Tween 60 40g and mix at high speed for 20 minutes to get mixed solution A.

[0057] S002. Take 50g of stearic acid and 80g of hydrogenated soybean oil, heat and melt at 80°C, add water-soluble vitamin K 3 6g, vitamin B 1 8g, vitamin B 2 50g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com