Anti-bioadhesive material, preparation method thereof and metal instrument coated with the same

An adhesive material and anti-biological technology, applied in coatings, medical science, surgery, etc., can solve problems such as cumbersome polymerization reactions, and achieve the effects of good biocompatibility, high stability, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

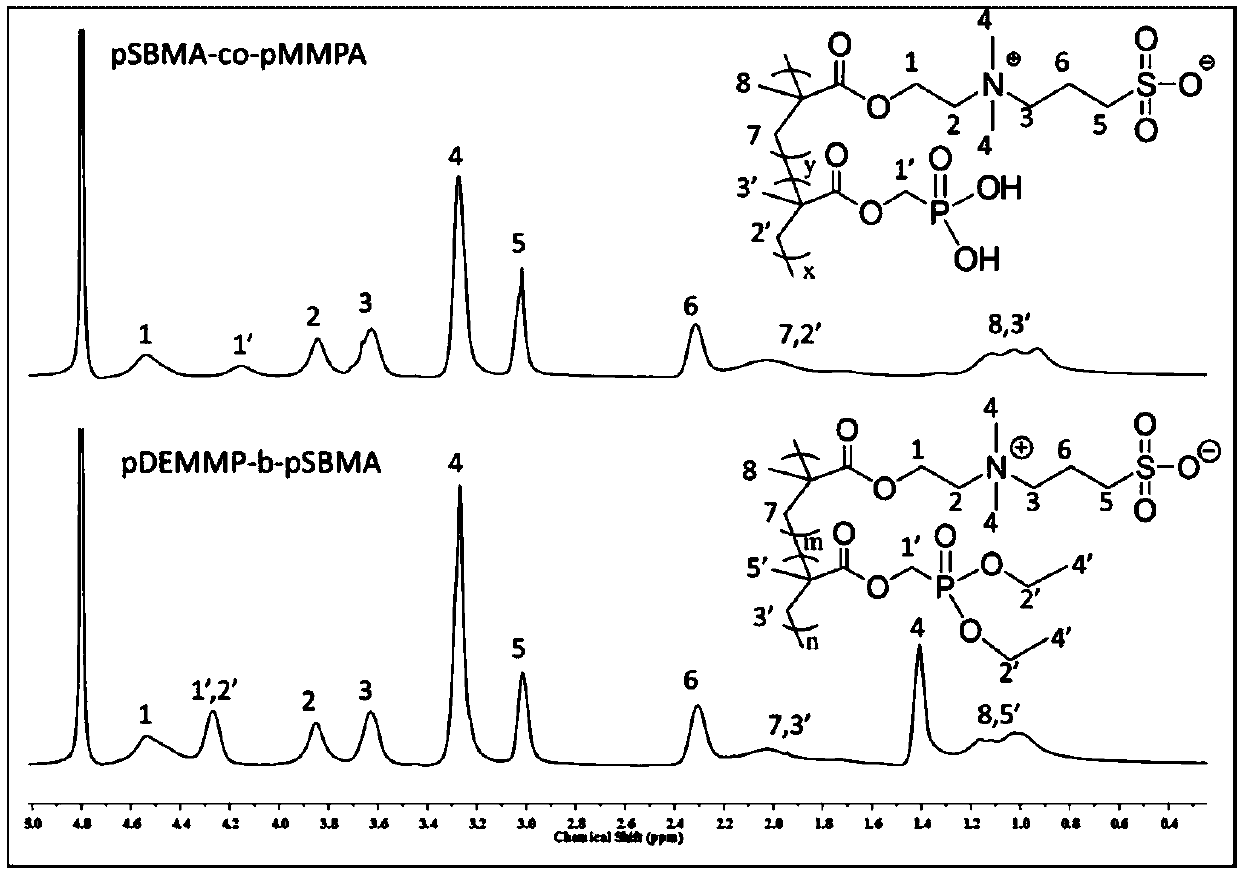

[0041] (1) The preparation method of anti-bioadhesion material is:

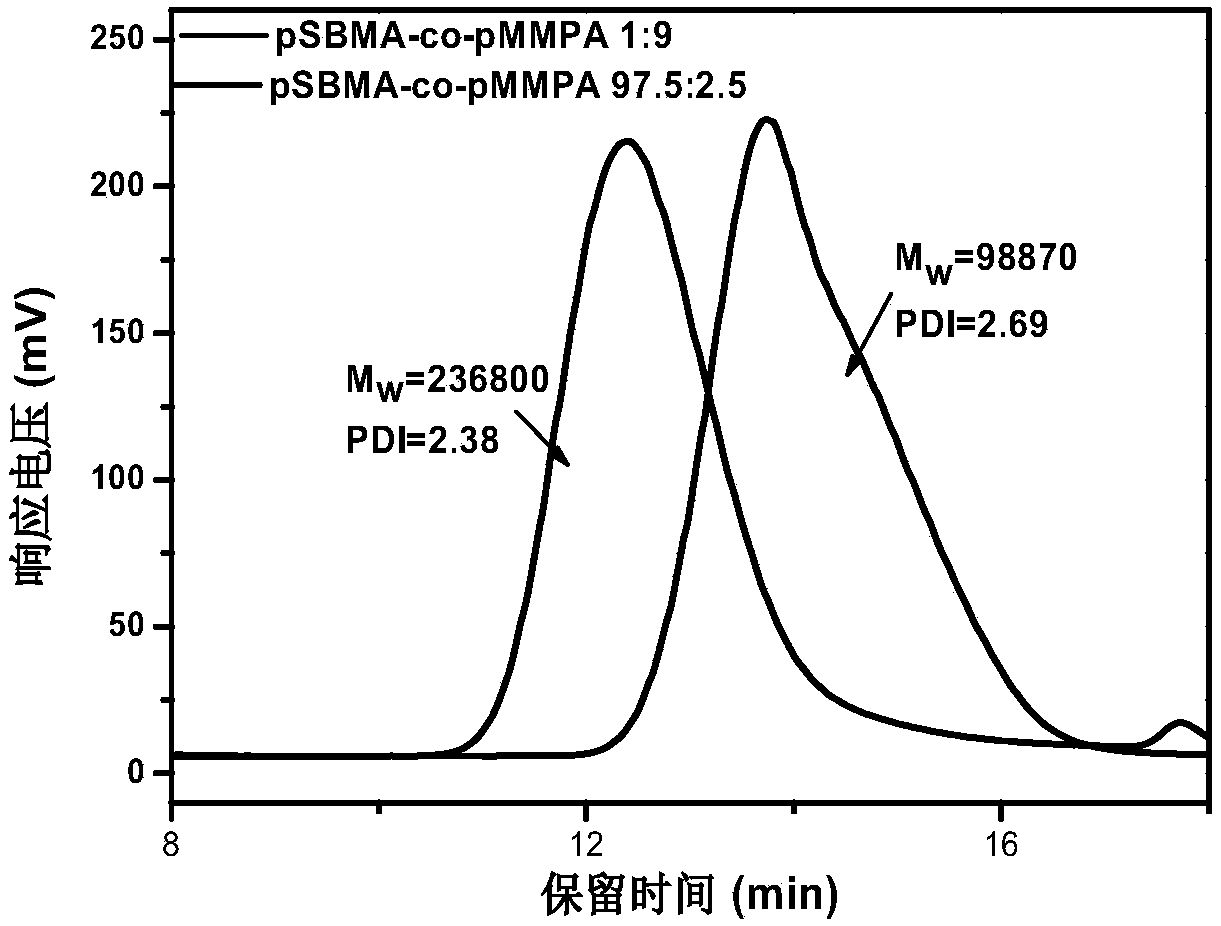

[0042] Under the protection of argon, (0.75mmol) sulfonamide zwitterionic monomer (n=2, m=3, R: methacrylate type) and (6.75mmol) phosphonic acid monomer (n=1, R 1 : H, R 2 : methacrylate type) was dissolved in water at a molar ratio of 1:9, then potassium persulfate (APS) (0.5 mmol) and tetramethylethylenediamine (TEMED) (11.25 μL) were added to the reaction system, and the Mix evenly and react at room temperature for 24 hours. The product is precipitated by methanol to obtain a white polymer. The polymer is vacuum-dried at room temperature to prepare a zwitterion / phosphonic acid copolymer with a molecular weight of 99,000 and a molecular weight dispersion coefficient of 2.7.

[0044] Phosphonic acid:

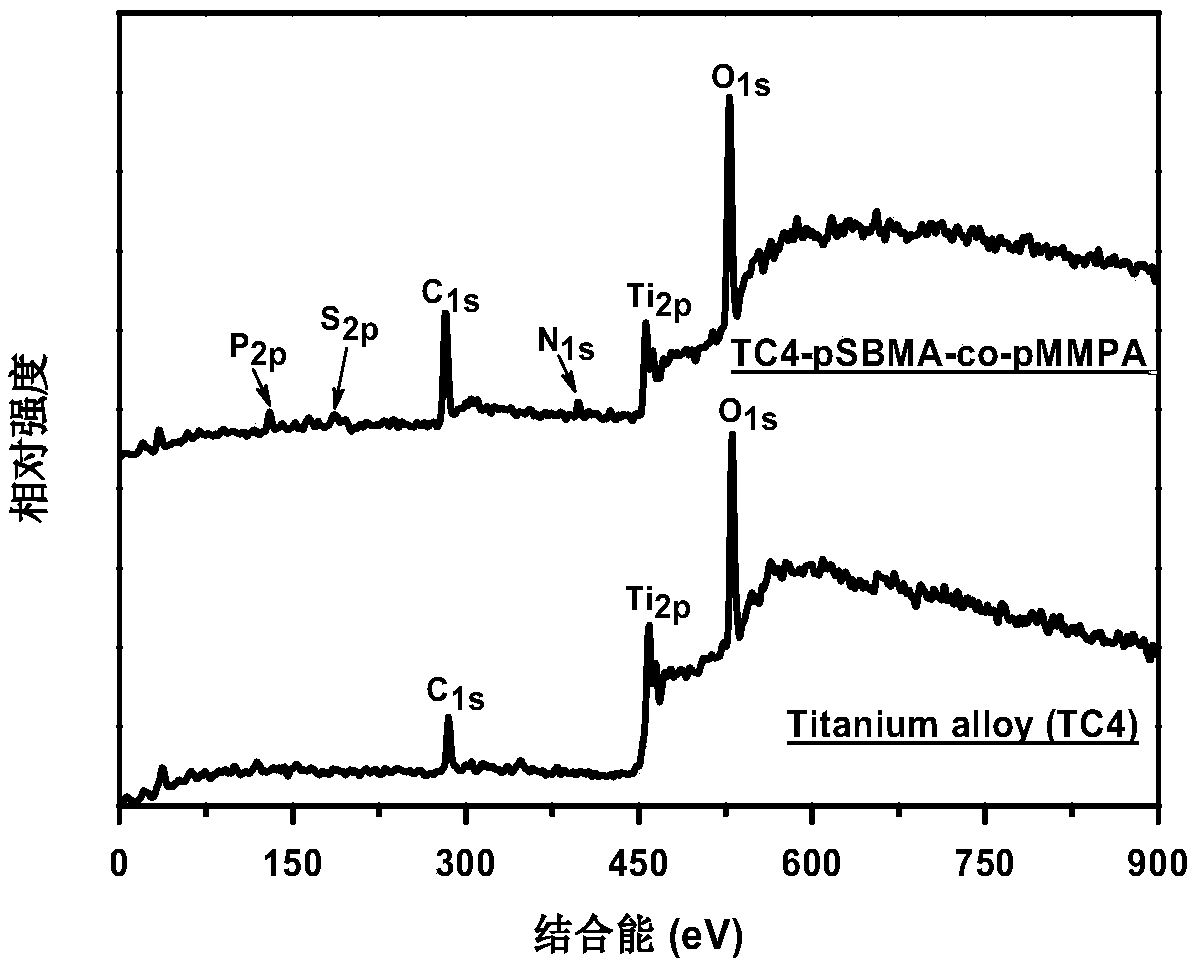

[0045] (2) The preparation method of the anti-bioadhesion titanium alloy material is:

[0046] Dissolve the copolymer prepared in step (1) in sterile PBS to prepare a 50 m...

Embodiment 2

[0048] (1) The preparation method of anti-bioadhesion material is:

[0049]Under nitrogen protection, (1 mmol) ammonium phosphate zwitterionic monomer (n=3, m=4, R: acrylate type) was dissolved in methanol (10 mL), and then ethyl 2-bromoisobutyrate (0.2 mmol), cuprous bromide (0.2mmol) / bipyridine (0.4mmol) were added to the reaction system, and after uniform mixing, they were reacted at 37°C for 12h, and the white polymer after precipitation with ether was vacuum-dried at room temperature to obtain Zwitterionic homopolymer. In the obtained zwitterionic homopolymer, add 39mmol phosphonic acid monomer, with phosphonic acid monomer (n=3, R 1 : H, R 2 : styrene type) as polymerized monomers, with zwitterionic homopolymer as macroinitiator (the mol ratio of phosphonic acid monomer and the ammonium phosphate zwitterionic monomer used to prepare homopolymer is 97.5: 2.5), through and Preparation of Zwitterionic Homopolymer Under the same polymerization conditions (monomer concentr...

Embodiment 3

[0055] (1) The preparation method of anti-bioadhesion material is:

[0056] Under the protection of argon, the carboxyammonium zwitterionic monomer (n=3, m=5, R: methacrylamide ester type) was dissolved in trifluoroethanol, and azobisisobutyronitrile, 2-cyano Base-2-propylbenzodisulfide is added to the reaction system (the molar ratio of each substance is carboxyammonium zwitterionic monomer: azobisisobutyronitrile: 2-cyano-2-propylbenzodisulfide=50: 1:1), mixed uniformly and reacted at 60°C for 24 hours, and the white polymer after ether precipitation was vacuum-dried at room temperature to obtain a zwitterionic homopolymer. Add phosphonate monomer in the zwitterionic homopolymer that makes, with phosphonate monomer (n=4, R 1 :OCH 2 CH 3 , R 2 : Vinyl type) is polymerized monomer, with zwitterionic homopolymer as macromolecular chain transfer agent (the molar ratio of phosphonate monomer and carboxyammonium zwitterionic monomer used for preparing homopolymer is 1:1), The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com