Efficient flame retardant dispersion liquid for epoxy resin and preparation method thereof

A technology for epoxy resin and epoxy resin, which is applied in the field of flame retardants, can solve the problems of reduced thermal stability and poor solubility, and achieves improved thermal stability and mechanical properties, good miscibility, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of high-efficiency flame retardant dispersion for epoxy resin, the specific steps are as follows:

[0028] Preparation of 5,10-dihydro-phosphazine-10-oxide (DPPA) (refer to RSC Advances, 2015, 5:68476–68484): 51.0 g of diphenylamine was added to the flask, and 44.0 g of three Phosphorus chloride, stirred for 30 minutes, gradually raised the temperature to 210°C, continued to stir for 7 hours, cooled to room temperature, and obtained a solid substance; after pulverizing the solid substance, gradually added 100mL of distilled water, heated and refluxed for 1 hour, and then cooled to 80°C , add 800mL of ethanol and stir thoroughly, filter while hot, wait for the filtrate to cool to room temperature, add excess 10% sodium hydroxide solution under stirring, adjust the pH of the solution to 10, filter to remove the precipitate; distill the ethanol in the filtrate to obtain DPPA Crude product, after washing to neutrality, DPPA is recrystallized with glacial acetic ...

Embodiment 2

[0034] To prepare the high-efficiency flame retardant dispersion liquid for epoxy resin, the specific steps are as follows:

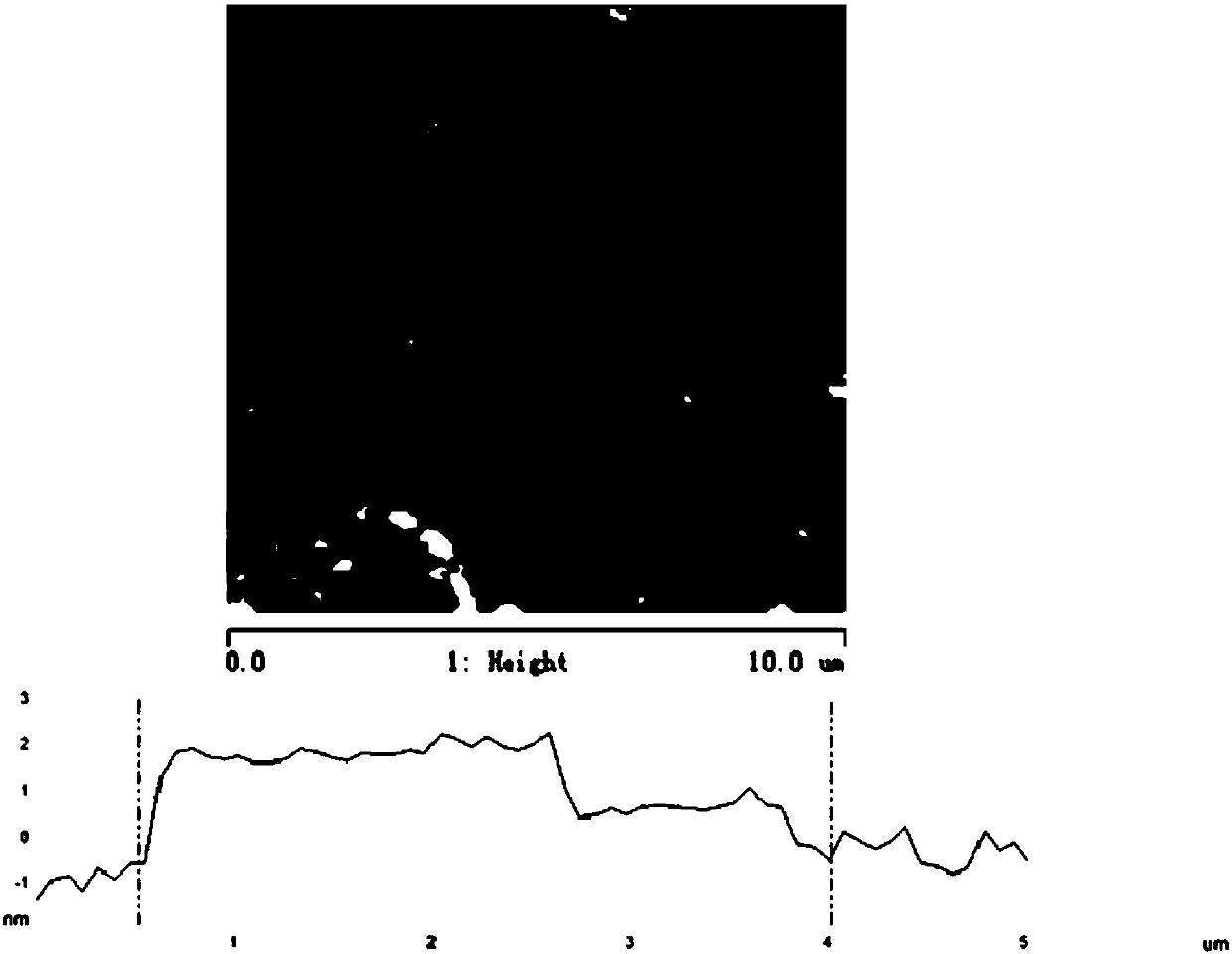

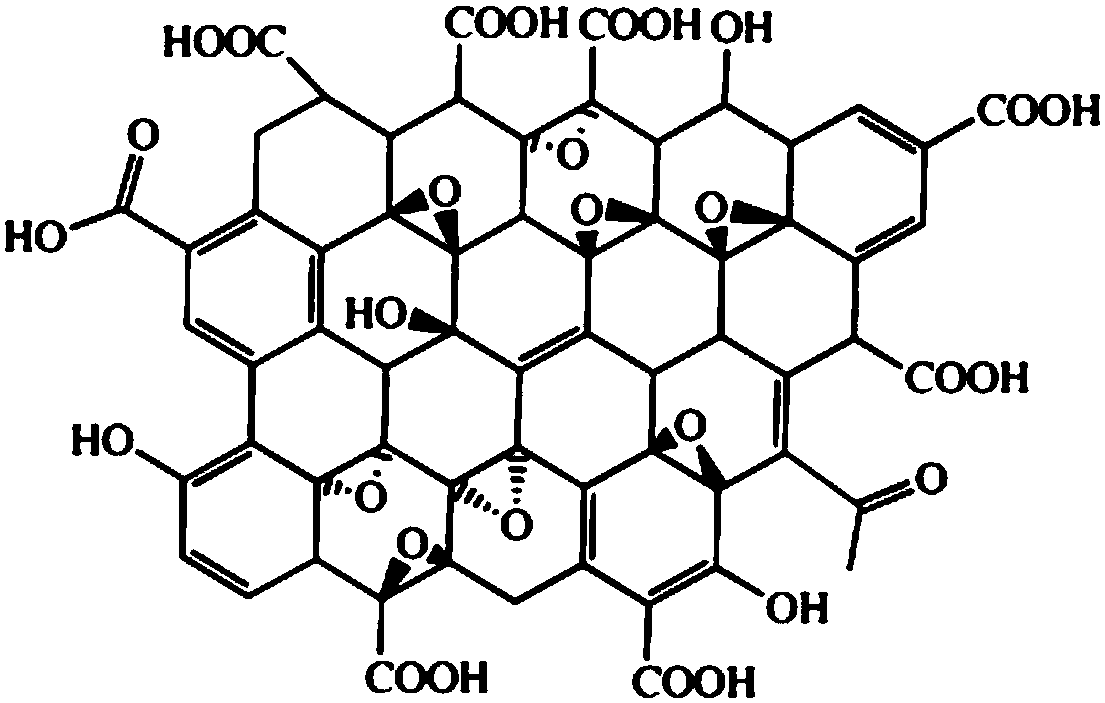

[0035] Preparation of graphite oxide: under an ice bath, add 1.0 g graphite, 4 g potassium permanganate, 25 g concentrated sulfuric acid with a mass concentration of 98% and 2.5 g phosphoric acid with a mass concentration of 85% in sequence, stir for 4 hours and then heat up to 55 ° C, the reaction 10h, then pour the reaction solution into 300mL ice water, add 10g of 30% hydrogen peroxide to react for 3h, centrifuge to separate the bottom solids; wash twice with 4% hydrochloric acid solution, and then deionize Washed with water until neutral, then filtered, and the obtained filter cake was dried in a vacuum drying oven at 55°C to obtain a yellow-brown solid product, namely graphite oxide;

[0036] The preparation of DPPA-coated graphene oxide dispersion: get 0.23g of above-mentioned graphite oxide and mix with 13.7g of absolute ethanol, add 2.27g of DPP...

Embodiment 3

[0039] To prepare the high-efficiency flame retardant dispersion liquid for epoxy resin, the specific steps are as follows:

[0040] Preparation of graphite oxide: under ice bath, add 1.0g graphite, 5g potassium permanganate, 20g concentrated sulfuric acid with a mass concentration of 98% and 3g phosphoric acid with a mass concentration of 85% in sequence, stir for 3 hours, then heat up to 65 ° C, and react for 12 hours , then poured the reaction solution into 250 mL of ice water, added 8 g of hydrogen peroxide with a mass concentration of 30%, reacted for 1 h, centrifuged, and collected the bottom solid; washed twice with a 4% mass concentration of hydrochloric acid solution, and then used deionized water Washed to neutrality, then filtered, and the obtained filter cake was dried in a vacuum drying oven at 60° C. to obtain a yellow-brown solid product, which was graphite oxide.

[0041] Preparation of DPPA-coated graphene oxide dispersion: get 0.44g of above-mentioned graphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com