Special tomato organic compound fertilizer and preparation method thereof

An organic fertilizer and tomato technology, which is applied in the field of special compound organic fertilizer for tomato and its preparation, can solve the problems of poor nutrient growth, decreased yield, soil compaction, etc., achieve good fertilizer efficiency and disease resistance, and improve tomato quality, yield, and elements. Reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

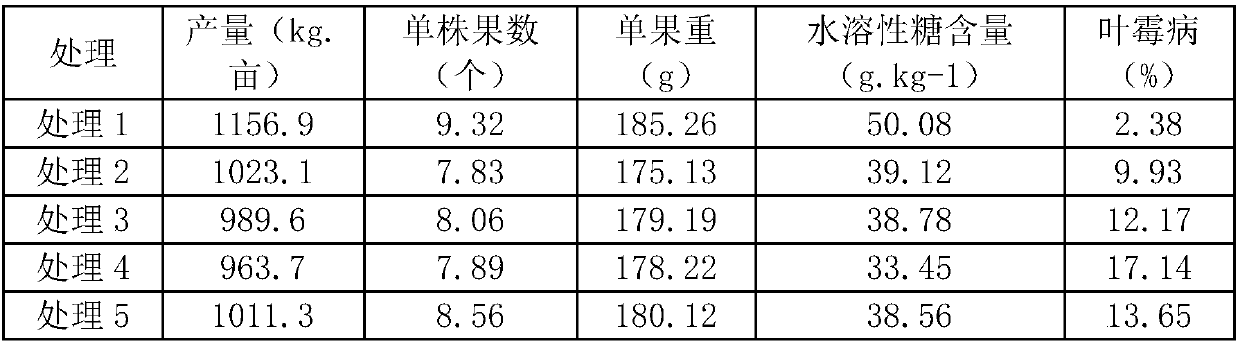

Image

Examples

Embodiment 1

[0021] Embodiment 1: special compound organic fertilizer for tomato, made by the following method:

[0022] a, 0.5 kg of Bacillus cereus, 0.25 kg of Bacillus megaterium, 0.25 kg of Rhodopseudomonas palustris, 0.15 kg of Candida utilis, 35 kg of L-glutamic acid, 55 kg of L-histidine, L - 35 kg of valine, 85 kg of humic acid, and 11 kg of earthworm mucus were mixed and stirred evenly, and reacted for 18 to 20 days at 30-35°C;

[0023] b. Add the mixture in step a to the ZLB rotary granulator of Changzhou Lixiong Machinery Manufacturing Co., Ltd. to make inner granules with a diameter of 1.8-2.2mm;

[0024] c. According to the parts by weight, take 30-40 parts of carboxymethyl starch, 2-3 parts of lauryl ether phosphate, and 60-70 parts of purified water and mix evenly;

[0025] d. Add the inner particles in step b to the LDP series bottom spray fluidized bed coating machine of Changzhou Panfeng Drying Equipment Co., Ltd., spray the solution in step c for coating to obtain slow-...

Embodiment 2

[0029] Embodiment 2: Special compound organic fertilizer for tomato, the preparation method is the same as in Example 1 and the difference is that the dosage ratio is: 80 kilograms of magnesium nitrate, 80 kilograms of ammonium bicarbonate, 100 kilograms of ammonium chloride, 140 kilograms of urea, and the degree of polymerization is 10~ 15 kg of ammonium polyphosphate, 60 kg of chitin, 2 kg of iron glycinate, 0.15 kg of Bacillus thuringiensis, and 280 kg of slow-release biological particles.

[0030] The dosage ratio of inner granules is: 0.4 kg of Bacillus cereus, 0.2 kg of Bacillus megaterium, 0.2 kg of Rhodopseudomonas palustris, 0.1 kg of Candida utilis, 30 kg of L-glutamic acid, 50 kg of L-histidine kg, L-valine 30 kg, humic acid 80 kg, earthworm slime 10 kg.

Embodiment 3

[0031] Embodiment 3: Special compound organic fertilizer for tomato, the preparation method is the same as that of Example 1. The difference is that the dosage ratio is: 100 kilograms of magnesium nitrate, 100 kilograms of ammonium bicarbonate, 120 kilograms of ammonium chloride, 160 kilograms of urea, and the degree of polymerization is 10~ 15 kg of ammonium polyphosphate, 70 kg of chitin, 3 kg of iron glycinate, 0.2 kg of Bacillus thuringiensis, and 300 kg of slow-release biological particles.

[0032] The dosage ratio of inner granules is: 0.6 kg of Bacillus cereus, 0.3 kg of Bacillus megaterium, 0.3 kg of Rhodopseudomonas palustris, 0.2 kg of Candida utilis, 40 kg of L-glutamic acid, 60 kg of L-histidine kg, L-valine 40 kg, humic acid 90 kg, earthworm slime 12 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com