Silver/cationic copolymer modified nano-diamond composite particle and preparation method thereof

A cationic copolymer, nanodiamond technology, applied in the fields of botanical equipment and methods, chemicals for biological control, biocides, etc., can solve the problem that Ag nanoparticles are easy to fall off, the particle size distribution is limited, and the antibacterial ability is insufficient. and other problems, to avoid the loss of macromolecules, fast and excellent antibacterial effect, and excellent antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

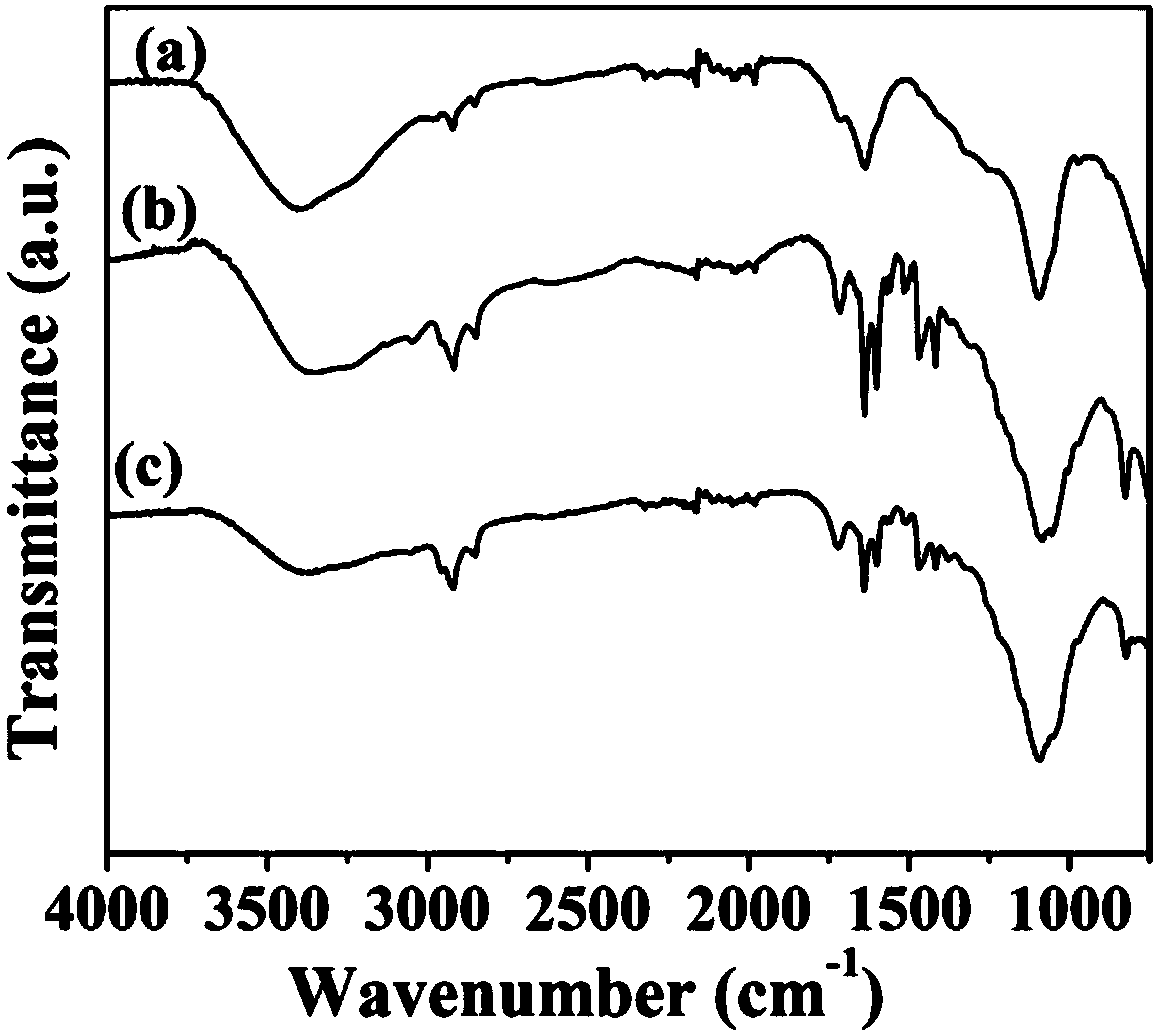

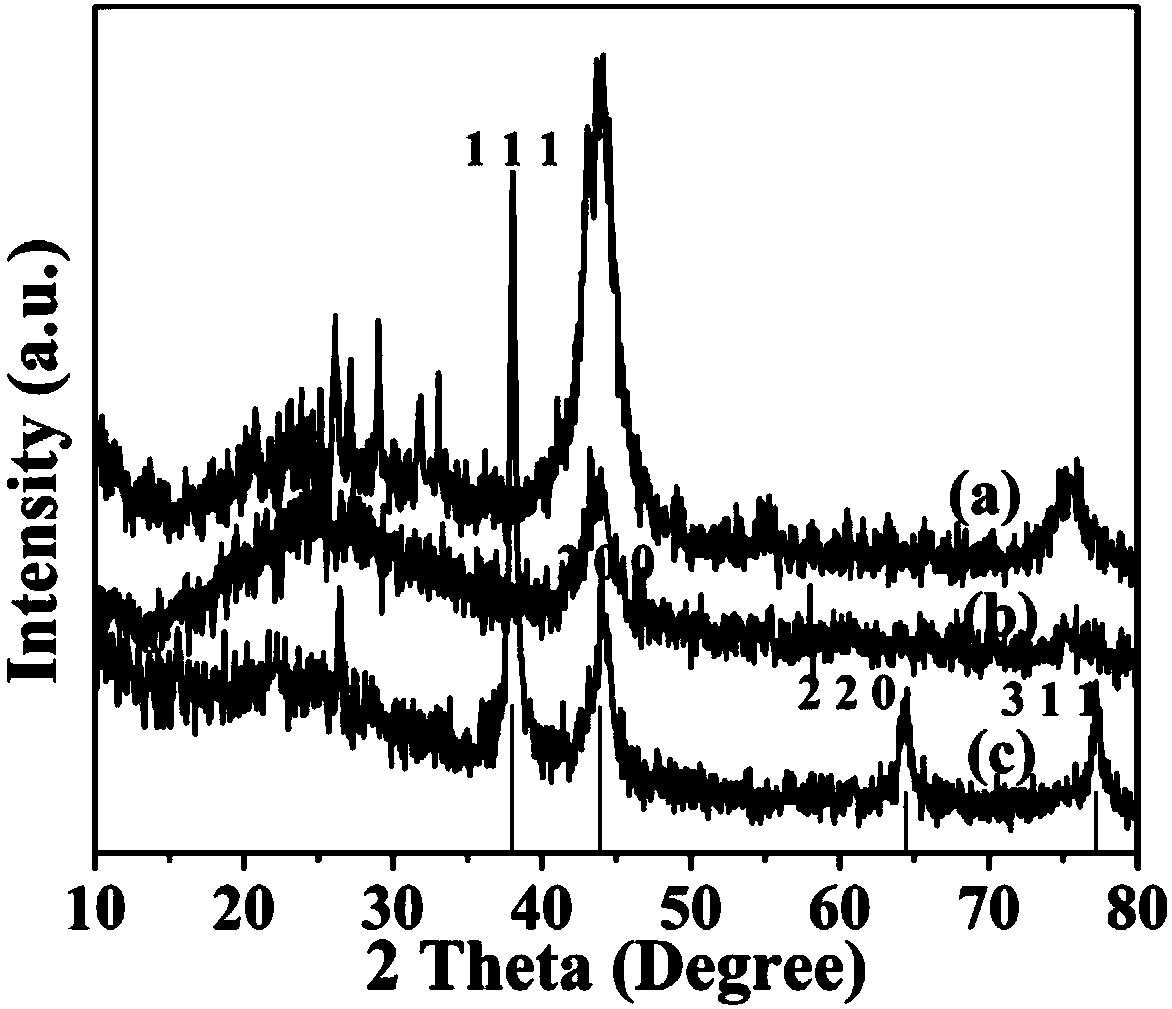

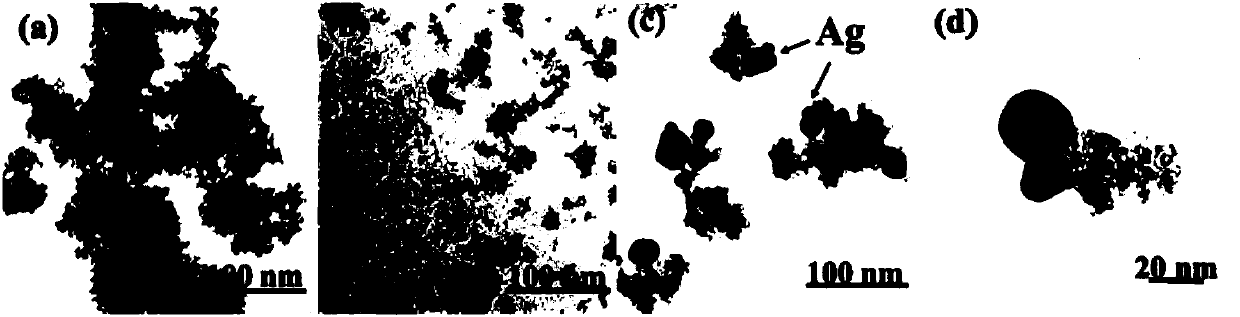

[0035] The preparation method of silver / cationic copolymer modified nano-diamond composite particle comprises the following steps:

[0036] a. Preparation of PVP-co-HEMA: Azobisisobutyronitrile (AIBN) was used as a thermal initiator, 4-vinylpyridine and hydroxyethyl methacrylate were mixed, heated and stirred, and the resulting mixture was precipitated in hexane three times and dried in vacuo.

[0037] b. ND was reacted with bromopropyltrimethoxysilane in aqueous alcohol solution, and the product (BrND) was centrifuged, washed and dried.

[0038] c.BrND reacts with PVP-co-HEMA in ethanol, and add excess hexyl bromide to fully quaternize PVP-co-HEMA, the product (QND) is centrifuged, washed, dried, and quaternized by adding excess hexyl bromide The degree is improved, the dispersibility of ND and the antibacterial performance of cationic polymer are improved.

[0039] d. Disperse the QND prepared above in distilled water and mix with AgNO 3 The aqueous solution is mixed and b...

Embodiment 1

[0041] Step a: Azobisisobutyronitrile AIBN is used as a thermal initiator to synthesize a copolymer by free radical polymerization. The molar ratio of 4-vinylpyridine monomer to hydroxyethyl methacrylate is 70 / 30. The mixture was stirred and heated in an oil bath at 60°C for 24 hours. Finally, the reaction mixture was precipitated three times in hexane and dried in a vacuum oven to obtain a pale yellow product.

[0042] Step b: Weigh raw material ND100mg and add to 20mL alcohol aqueous solution (V 乙醇 :V 水 =9:1), then add silane coupling agent (bromopropyltrimethoxysilane) according to 10% (10mg) of ND mass, stir magnetically at 50°C for 24h, centrifuge the product, wash three times with deionized water, Dry in a vacuum oven at 60°C.

[0043]Step c: Dissolve 50mg BrND in 20ml ethanol solution, add 50mg copolymer PVP-co-HEMA, react at 70°C for 24h, then add excess bromide hexane (0.12g) to make it fully quaternized, centrifuge the product, and use Washed three times with et...

Embodiment 2

[0053] Step a: The molar ratio of 4-vinylpyridine monomer to hydroxyethyl methacrylate is 95 / 5.

[0054] Step d: Mass ratio, nano-diamond: silver nitrate: sodium citrate = 1: 1.2: 1.4, keep the solution boiling for 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com