Thianthrene-containing pentabasic condensed nucleus unit derivative and its synthetic method and application

A synthesis method and derivative technology, applied in the field of five-membered fused ring unit derivatives and their synthesis, can solve the problems of insufficient efficiency of light-emitting materials, and achieve the effects of inhibiting molecular aggregation, conjugation enhancement, and good site selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

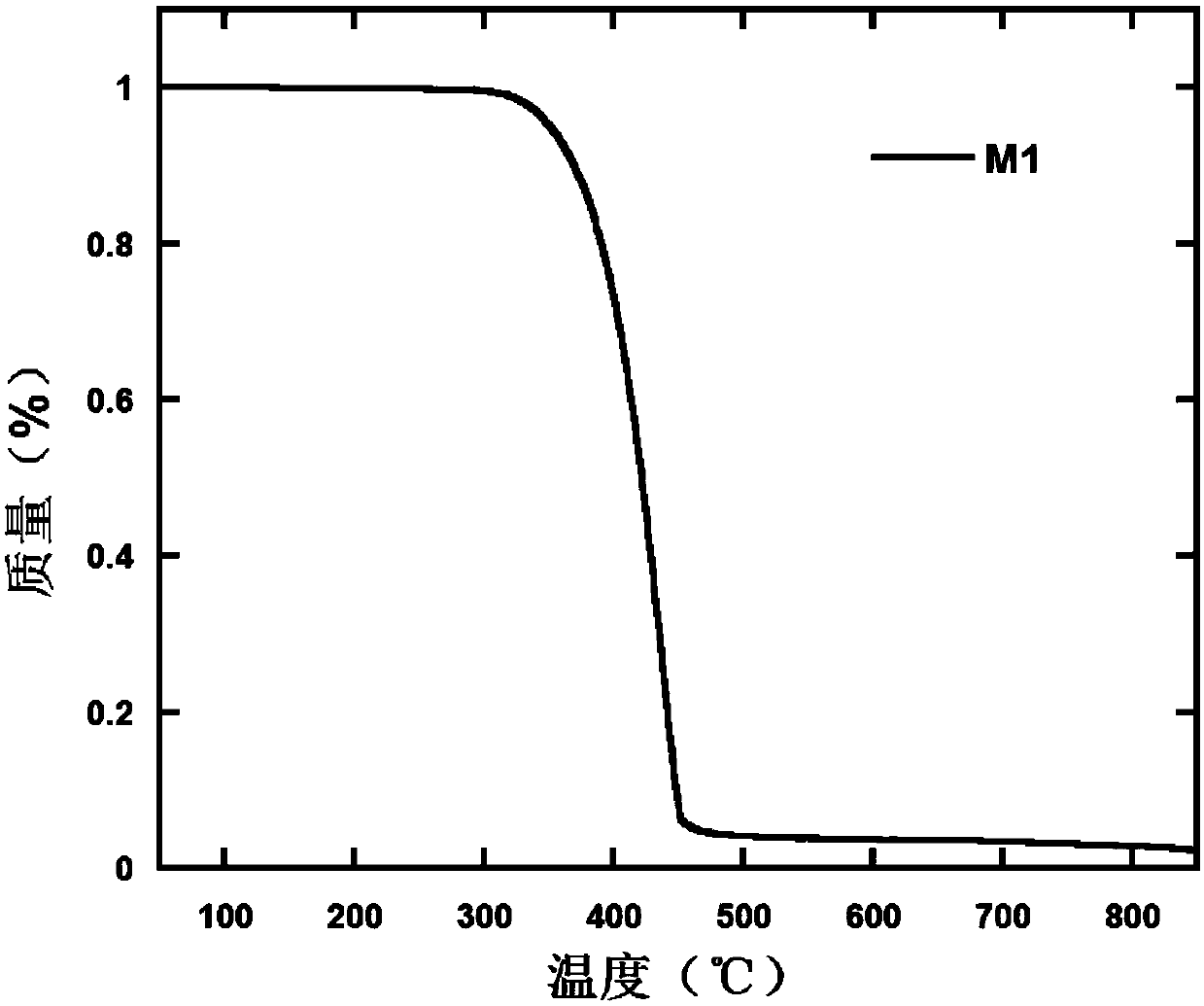

[0033] Synthesis of compounds M1 and M2

[0034] (1) Preparation of compound 1

[0035] Under nitrogen protection, add 3-bromo-dibenzothiophene (2.63g, 10mmol), 1,2-benzenedithiol (1.42g, 10mmol), sodium tert-butoxide (4.81g, 50mmol) into a 300ml two-necked flask , tris(dibenzylideneacetone)dipalladium (458mg, 0.5mmol), bis(2-diphenylphosphophenyl)ether (269mg, 0.5mmol) and 150ml toluene, heated to 80°C and stirred for 12 hours. After the reaction was completed, the product was extracted with dichloromethane, the organic phase was washed with saturated aqueous sodium chloride solution, the solvent was evaporated under reduced pressure, and the crude product was eluted with a mixed solvent of petroleum ether:dichloromethane=8:1 (v / v) Purified by solvent column chromatography to obtain 1.85 g of white solid with a yield of 57%. 1 H NMR, 13 The results of CNMR, MS and elemental analysis showed that the obtained compound was the target product.

[0036] (2) Preparation of Comp...

Embodiment 2

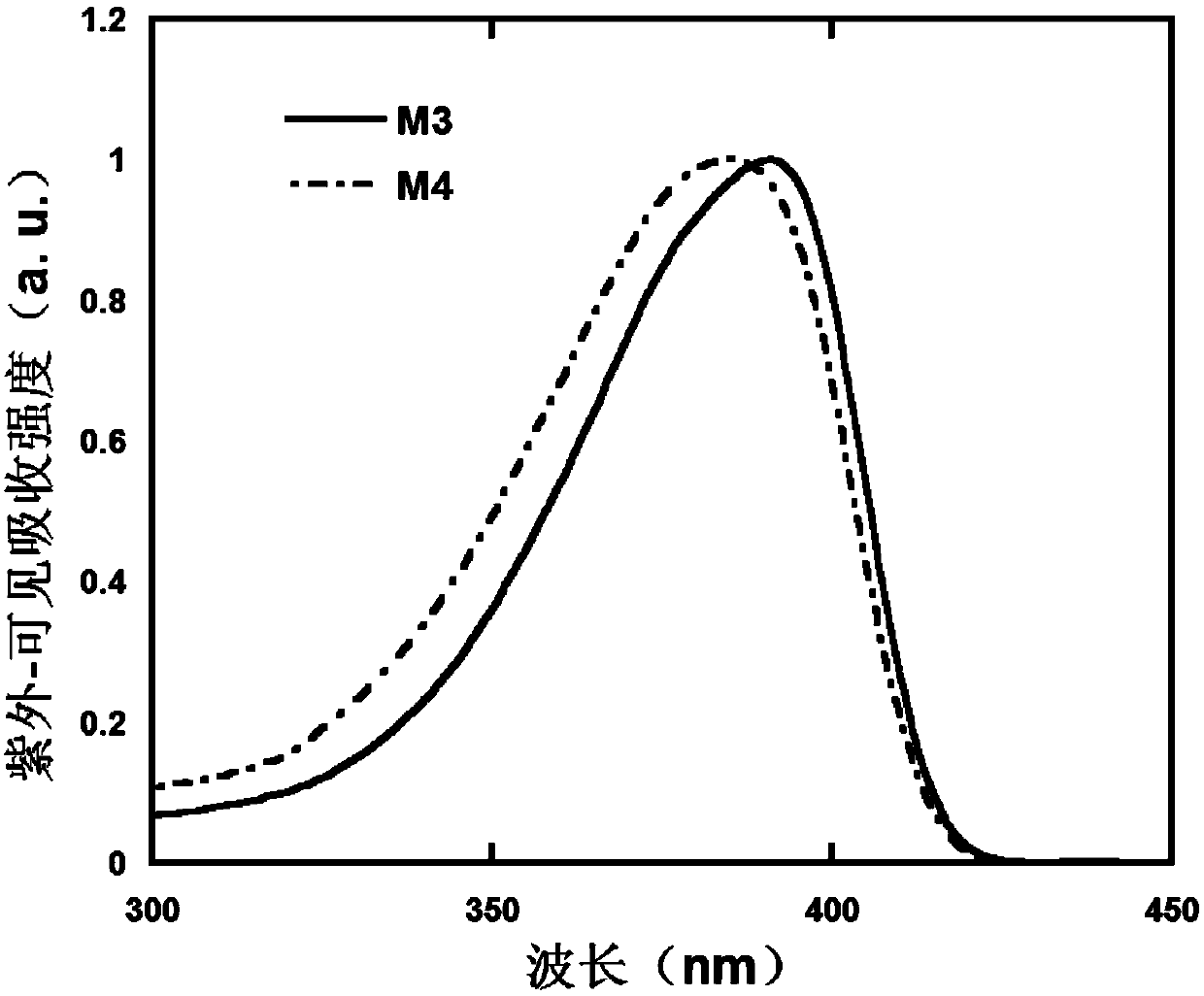

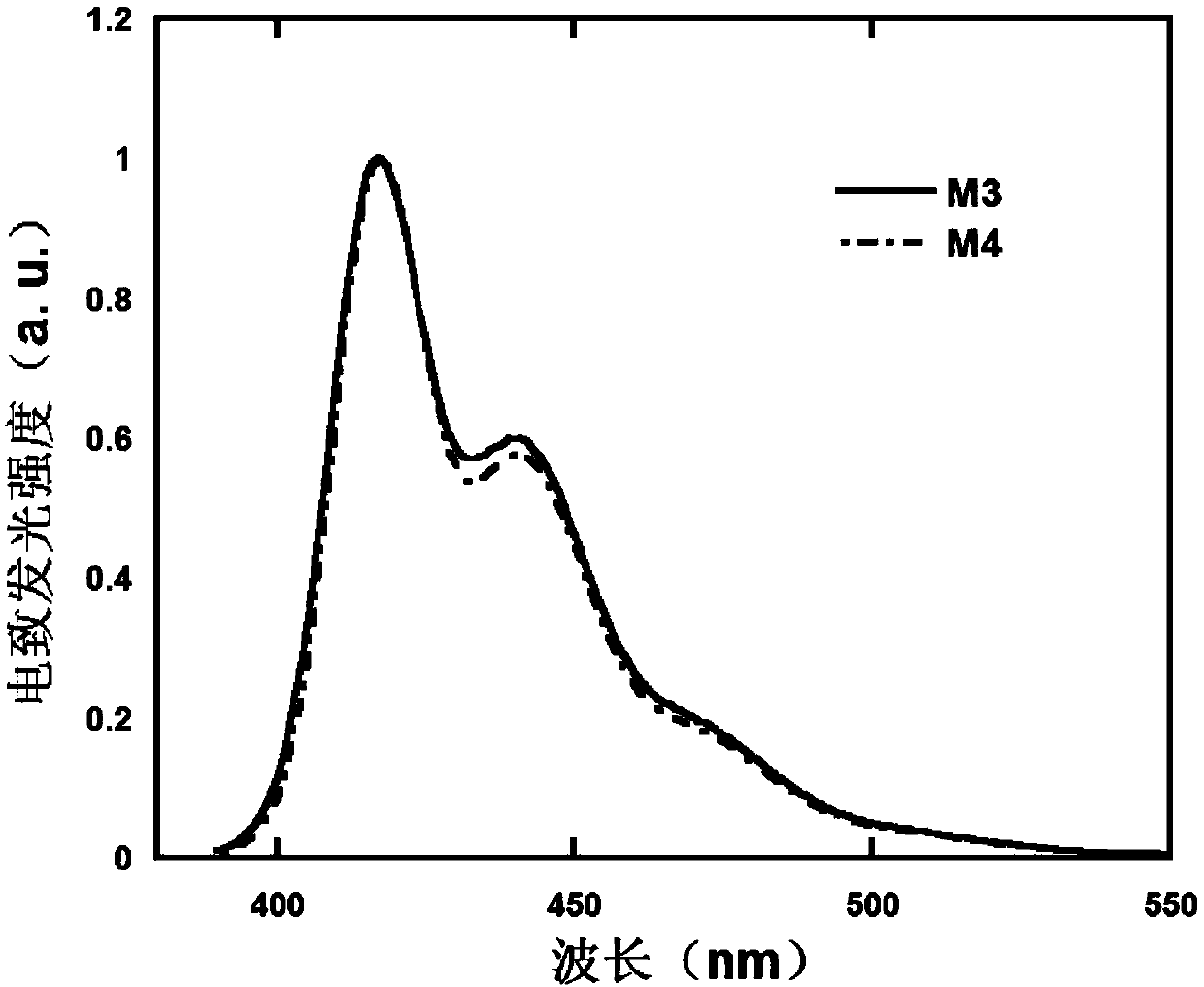

[0047] Synthesis of compounds M3 and M4

[0048] (1) Synthesis of compound 4

[0049] Under nitrogen protection, 2,7-dibromo-9,9-dioctylfluorene (5.48g, 10mmol), 4-(4,4,5,5-tetramethyl-1, 3-dioxo-2-boryl) triphenylamine (2.89g, 10mmol), potassium carbonate (3.45g, 25mmol), tetrakis (triphenylphosphine) palladium (0.58g, 0.5mmol), 12ml deionized water and 120ml of toluene was heated to 80°C for 12 hours. After the reaction is complete, the product is extracted with dichloromethane, washed three times with saturated aqueous sodium chloride solution, and the organic phase solvent is removed, and the crude product is washed with a mixed solvent of petroleum ether:dichloromethane=8:1 (v / v) Purified by column chromatography to obtain 5.51 g of off-white solid with a yield of 77%. 1 H NMR, 13 The results of CNMR, MS and elemental analysis showed that the obtained compound was the target product.

[0050] (2) Synthesis of compound 5

[0051] Under nitrogen protection, compound 4...

Embodiment 3

[0061] Preparation of Compounds M5 and M6

[0062] (1) Preparation of Compound 8

[0063] Under nitrogen protection, 2-iodo-dibenzofuran (2.94g, 10mmol), 4-bromo-1,2-benzenedithiol (2.21g, 10mmol), sodium tert-butoxide (4.81 g, 50mmol), tris(dibenzylideneacetone)dipalladium (458mg, 0.5mmol), bis(2-diphenylphosphophenyl)ether (269mg, 0.5mmol) and 150ml toluene, heated to 50°C and stirred the reaction 8 hours. After the reaction was completed, the product was extracted with dichloromethane, the organic phase was washed with saturated aqueous sodium chloride solution, the solvent was evaporated under reduced pressure, and the crude product was eluted with a mixed solvent of petroleum ether:dichloromethane=8:1 (v / v) Purified by solvent column chromatography to obtain 2.34 g of white solid with a yield of 60%. 1 H NMR, 13 The results of CNMR, MS and elemental analysis showed that the obtained compound was the target product.

[0064] (2) Preparation of Compound 9

[0065] Und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com