Modified sodium alginate electrospun fibre hemostatic membrane and preparation method thereof

A technology of sodium alginate and electrospun fibers, which is applied in the fields of pharmaceutical formula, medical science, and absorbent pads, etc., can solve the problems of single molding method and limited application of hemostatic materials, so as to broaden the application range, improve soft compressibility, reduce Effects on discomfort and pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (1) Preparation of thiolated sodium alginate

[0033] Weigh a certain mass of sodium alginate and dissolve it in distilled water to prepare a sodium alginate solution with a mass concentration of 2%, then add a sodium hydroxide solution with a molar concentration of 2mol / L to adjust the pH of the sodium alginate solution to 4, and then press Mass ratio sodium alginate: N-hydroxysuccinimide (NHS): 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC)=1:0.1:0.2 added N-hydroxysuccinimide and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, stirred at room temperature for 2h, and then according to the mass ratio of sodium alginate: cysteine methyl ester Hydrochloride=1:1 Add cysteine methyl ester hydrochloride, stir at room temperature for 12 hours, then add a large amount of absolute ethanol to precipitate the reaction product, filter with suction, and then wash with absolute ethanol 2-3 times, 45 °C and vacuum-dried to obtain mercaptolated so...

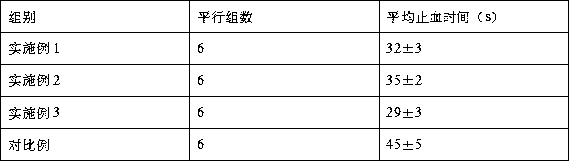

Embodiment 1

[0042] According to the present invention, a modified sodium alginate electrospun fiber hemostatic membrane is prepared according to the above method, wherein: the molecular weight of the polyvinyl alcohol used in the preparation process is 80000, and the molecular weight of the sodium alginate used is 1 × 10 6 kDa; The electrospinning machine used is the TL-192 electrospinning machine produced by Shenzhen Tongli Micro-Nano Co., Ltd. The parameters of the outer fiber film spinning are set as follows: high-voltage power supply voltage: 18kV, winding device rotation speed: 2000 rpm , output pump flow rate: 75 mL / h; the parameters of inner layer composite fiber membrane spinning are set as follows: high voltage power supply voltage 22 kV, winding device rotation speed: 1000 rpm, output pump flow rate: 50 mL / h; calculated by weight parts It is composed of 10 parts of polyvinyl alcohol and 5 parts of thiolated alginic acid.

Embodiment 2

[0044] According to the present invention, a modified sodium alginate electrospun fiber hemostatic membrane is prepared according to the above method, wherein: the molecular weight of the polyvinyl alcohol used in the preparation process is 80000, and the molecular weight of the sodium alginate used is 1 × 10 6 kDa; The electrospinning machine used is the TL-192 electrospinning machine produced by Shenzhen Tongli Micro-Nano Co., Ltd. The parameters of the outer fiber film spinning are set as follows: high-voltage power supply voltage: 18kV, winding device rotation speed: 2000 rpm , output pump flow rate: 100 mL / h; the parameters of inner layer composite fiber membrane spinning are set as follows: high voltage power supply voltage: 22kV, winding device rotation speed: 1500 rpm, output pump flow rate: 75 mL / h; by weight parts It consists of 20 parts of polyvinyl alcohol and 10 parts of thiolated alginic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com