Expansible ceramic silicone rubber composite material and preparation method thereof

A technology of composite materials and silicone rubber, which is applied in the field of rubber materials, can solve the problems of low thermal stability, heat release rate, inability to meet the expansion seal, and no seal expansion, so as to increase the preparation reaction speed, improve the mechanical properties, reduce the ceramic The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

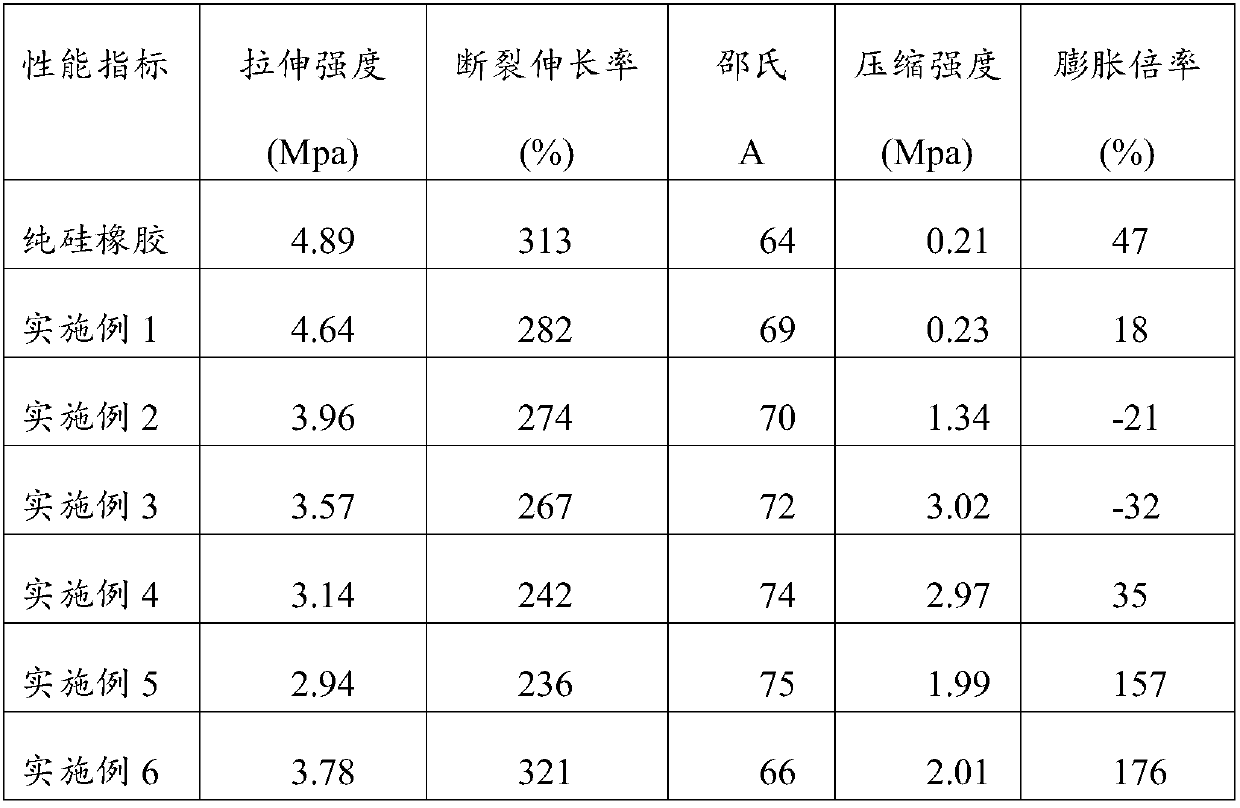

Examples

Embodiment 1

[0026] A kind of preparation method of expansion porcelain silicon rubber composite material of the present invention, comprises the following steps:

[0027] 1) Mix 100g of methyl vinyl silicone rubber raw rubber, 20g of porcelain filler, and 30g of reinforcing filler in a twin-roller mixer for 10 minutes, mix well, and the molecular weight of the methyl vinyl silicone rubber raw rubber is greater than 500,000, the porcelain filler is made of mica, and the reinforcing filler is calcium carbonate. The above 20g porcelain filler is dried in an oven at 80°C for 7 hours to ensure that the porcelain material is fully dried and the prepared porcelain silicone rubber has good physical and chemical properties. properties, especially mechanical and electrical properties;

[0028] 2) Add 2g of vulcanizing agent to the above mixture to obtain mixed rubber, and the sheet is produced. The above vulcanizing agent is selected from 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (commonly known...

Embodiment 2

[0031] 1) Blend 100g of methyl vinyl silicone rubber raw rubber with 18g of porcelain filler, 10g of flux, and 25g of reinforcing filler in an internal mixer for 10 minutes, and mix evenly. The molecular weight is greater than 500,000, kaolin is used as the porcelain filler, the flux is a mixture of glass powder with a melting point of 500°C and glass powder with a melting point of 400°C in a ratio of 1:1, and white carbon black is used as a reinforcing filler;

[0032] 2) Add 2g of methyl silicone oil to the above-mentioned internal mixer and continue blending to form a uniformly mixed rubber;

[0033] 3) Add 2.5g of vulcanizing agent to the above-mentioned uniformly mixed rubber, and release the sheet. The above-mentioned vulcanizing agent is selected from 2,4-benzoyl dichloride oxide (commonly known as double 2,4);

[0034] 4) Vulcanize the mixed rubber obtained in the above 3) at 160°C and 12Mpa pressure for 12 minutes to make the required sample and perform a performance ...

Embodiment 3

[0036] 1) Mix 100g of methyl vinyl silicone rubber raw rubber, 10g of porcelain filler, 20g of flux, and 28g of reinforcing filler in a twin-roller mixer for 15 minutes, and mix well; the methyl vinyl silicone rubber raw The molecular weight of the glue is greater than 500,000. Aluminum hypophosphite is used as the porcelain filler. The flux is a mixture of glass powder with a melting point of 500°C and glass powder with a melting point of 400°C in a ratio of 1:1. The reinforcing filler is zinc oxide, The combination of titanium dioxide, the combination ratio is 1:1.

[0037] 2) Add 3g of methyl silicone oil into the mixer to continue blending;

[0038] 3) 3g of vulcanizing agent is added to the mixture obtained in the above step 2) to form a mixed rubber, and the sheet is produced; the above-mentioned vulcanizing agent is selected from dicumyl peroxide (commonly known as DCP);

[0039] 4) Vulcanize the mixed rubber obtained in the above 3) at 120°C and 16Mpa pressure for 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com