High-adhesion-strength low-temperature curing conductive silver adhesive used for piezoelectric composite material and preparation method of adhesive

A technology of piezoelectric composite materials and conductive silver glue, applied in the direction of conductive adhesives, applications, adhesives, etc., can solve the problem that the bonding strength and welding adhesion cannot be maximized, and the bonding strength between the silver layer and the solder joint Poor bonding strength, long curing time and other problems, to achieve the effect of low cost, high bonding strength of silver layer and solder joint, and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

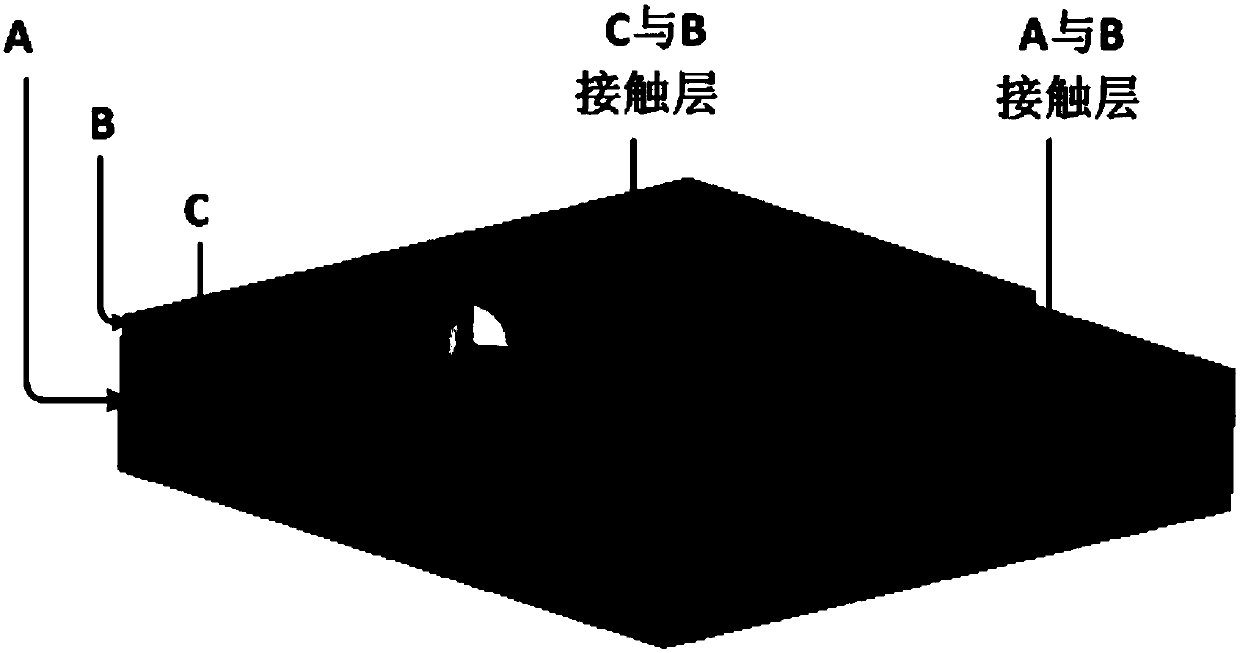

Image

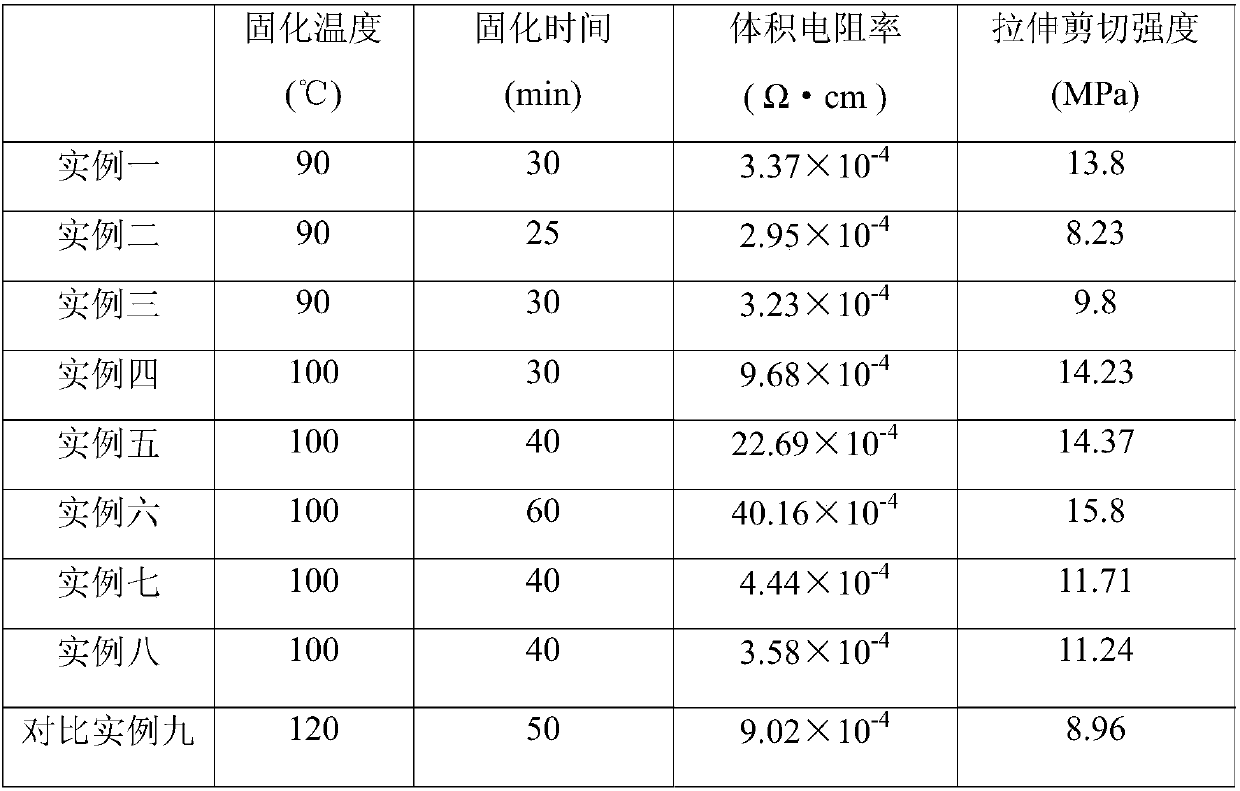

Examples

example 1

[0025] Step 1: Stir the epoxy resin, curing agent and other additives in proportion at room temperature for 5-10 minutes to make them fully mixed, and place them in a vacuum incubator for defoaming treatment to obtain the corresponding resin matrix solution. According to relevant theoretical analysis and a large number of experimental verification comparisons, it is found that when epoxy resin: curing agent: other additives = 100:150:10 (mass ratio), the conductivity and adhesion are better.

[0026] Step 2: First preheat the weighing bottle, then add a certain amount of solvent dropwise, then take a certain amount of prepared resin matrix solution, then add nano-silver powder in batches, and stir for 20-30 minutes until a silver-white slurry is formed . According to relevant theoretical analysis and a large number of experimental verification comparisons, the amount of solvent taken accounts for 8-15% of the total, the resin matrix solution accounts for 17-37% of the total, a...

example 2

[0030] Example two: Take epoxy resin: curing agent: other additives = 100:200:10, the implementation of steps and the use of reagents are all unchanged according to example one.

example 3

[0031] Example three: take epoxy resin: curing agent: other additives = 100:180:10, the implementation of steps and the use of reagents are all unchanged according to example one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com