Degradable composite material and preparation method thereof

A composite material and raw material technology, applied in the field of degradable composite materials and its preparation, can solve problems such as uneven plant fibers, and achieve the effects of improving mechanical properties, stability, and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

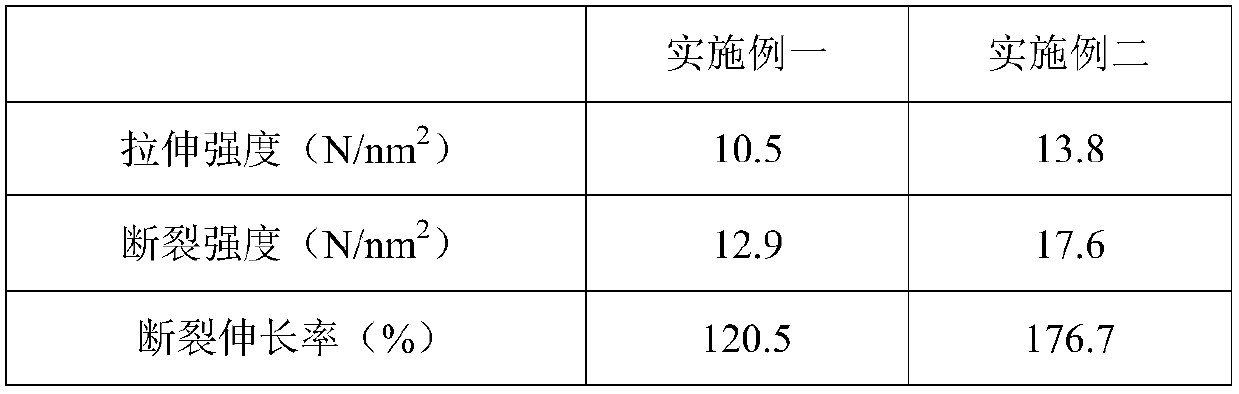

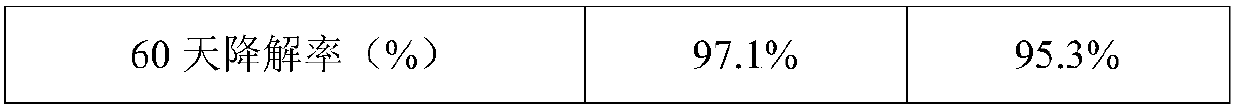

Examples

Embodiment 1

[0020] Take the raw materials of following weight ratio and make:

[0021] 30 parts of polyethylene, 20 parts of bacterial cellulose, 10 parts of cyclodextrin, 30 parts of polylactic acid, 30 parts of polybutylene succinate, 6 parts of zymosan, 2 parts of acetyl chloride, 2 parts of n-octanol, silane 2 parts of coupling agent, 5 parts of chitosan, 5 parts of maleic anhydride grafted polyethylene, 1 part of gum arabic, 1 part of epichlorohydrin, 1 part of acetyl tributyl citrate, and 2 parts of polyvinyl acetate.

[0022] Prepare as follows:

[0023] (1) Add bacterial cellulose, chitosan, acetyl chloride, silane coupling agent, and n-octanol to the reaction vessel, react for 6 hours at 80°C, wash the reaction product with water until neutral, and put Put it into a freeze dryer and dry for 12 hours, pulverize with a ball mill until the particle size is below 200 mesh, and sieve to obtain the modified bacterial cellulose powder.

[0024] (2) Add polyethylene, cyclodextrin, zymo...

Embodiment 2

[0028] Take the raw materials of following weight ratio and make:

[0029] 40 parts of polyethylene, 30 parts of bacterial cellulose, 20 parts of cyclodextrin, 40 parts of polylactic acid, 40 parts of polybutylene succinate, 14 parts of zymosan, 6 parts of acetyl chloride, 8 parts of n-octanol, silane 10 parts of coupling agent, 12 parts of chitosan, 15 parts of maleic anhydride grafted polyethylene, 8 parts of gum arabic, 6 parts of epichlorohydrin, 6 parts of acetyl tributyl citrate, and 8 parts of polyvinyl acetate.

[0030] Prepare as follows:

[0031] (1) Add bacterial cellulose, chitosan, acetyl chloride, silane coupling agent, and n-octanol to the reaction vessel, react for 3 hours at 120°C, wash the reaction product with water until neutral, and put Put it into a freeze dryer and dry it for 120 hours, pulverize it with a ball mill until the particle size is below 200 mesh, and sieve to obtain the modified bacterial cellulose powder.

[0032] (2) Add polyethylene, cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com