Sewage treatment system for dye printing

A sewage treatment system and sludge treatment technology, applied in water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve the complex composition of printing and dyeing wastewater, reduce the content of trace elements in water body, and a single treatment method Unable to achieve the ideal treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

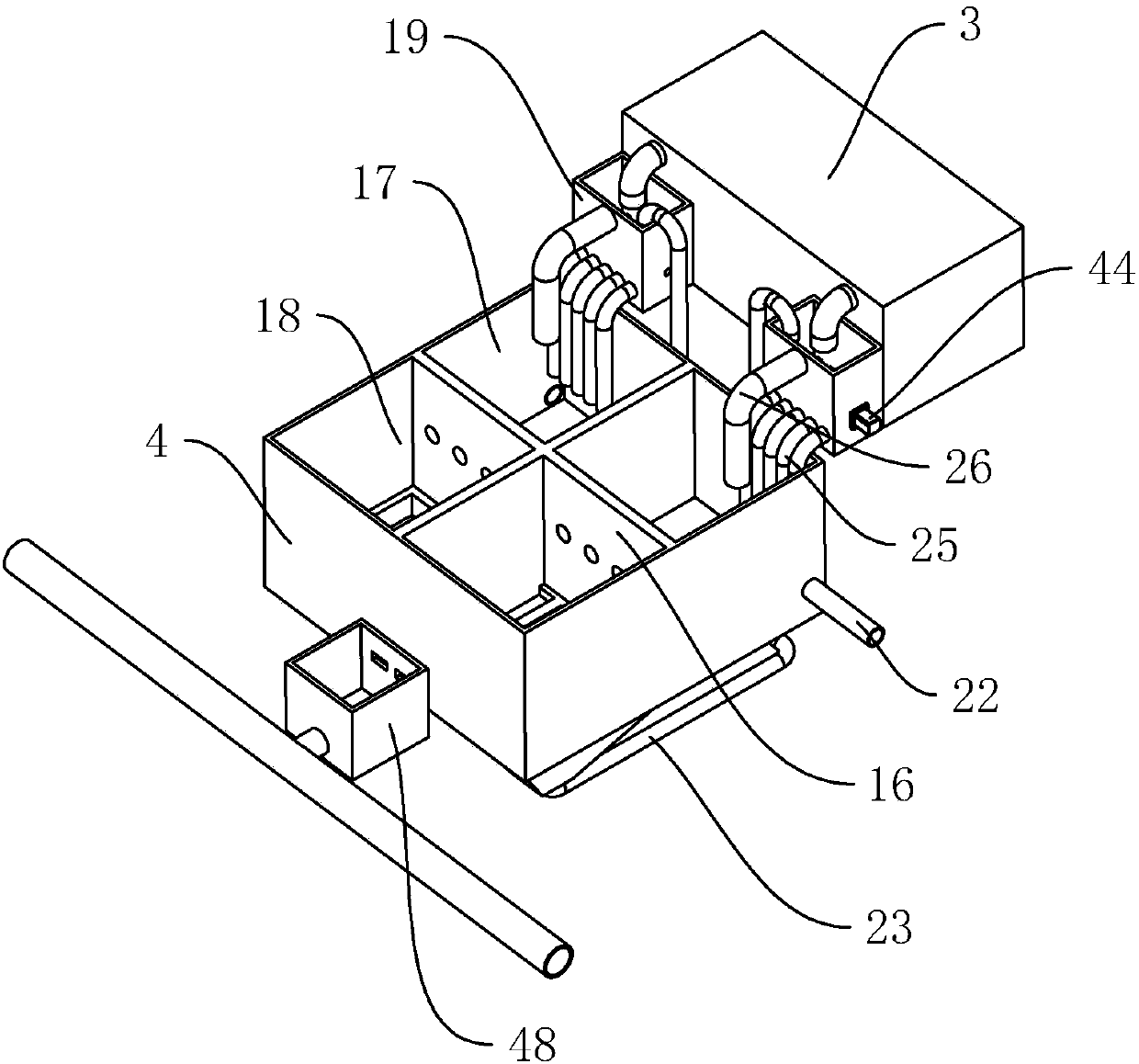

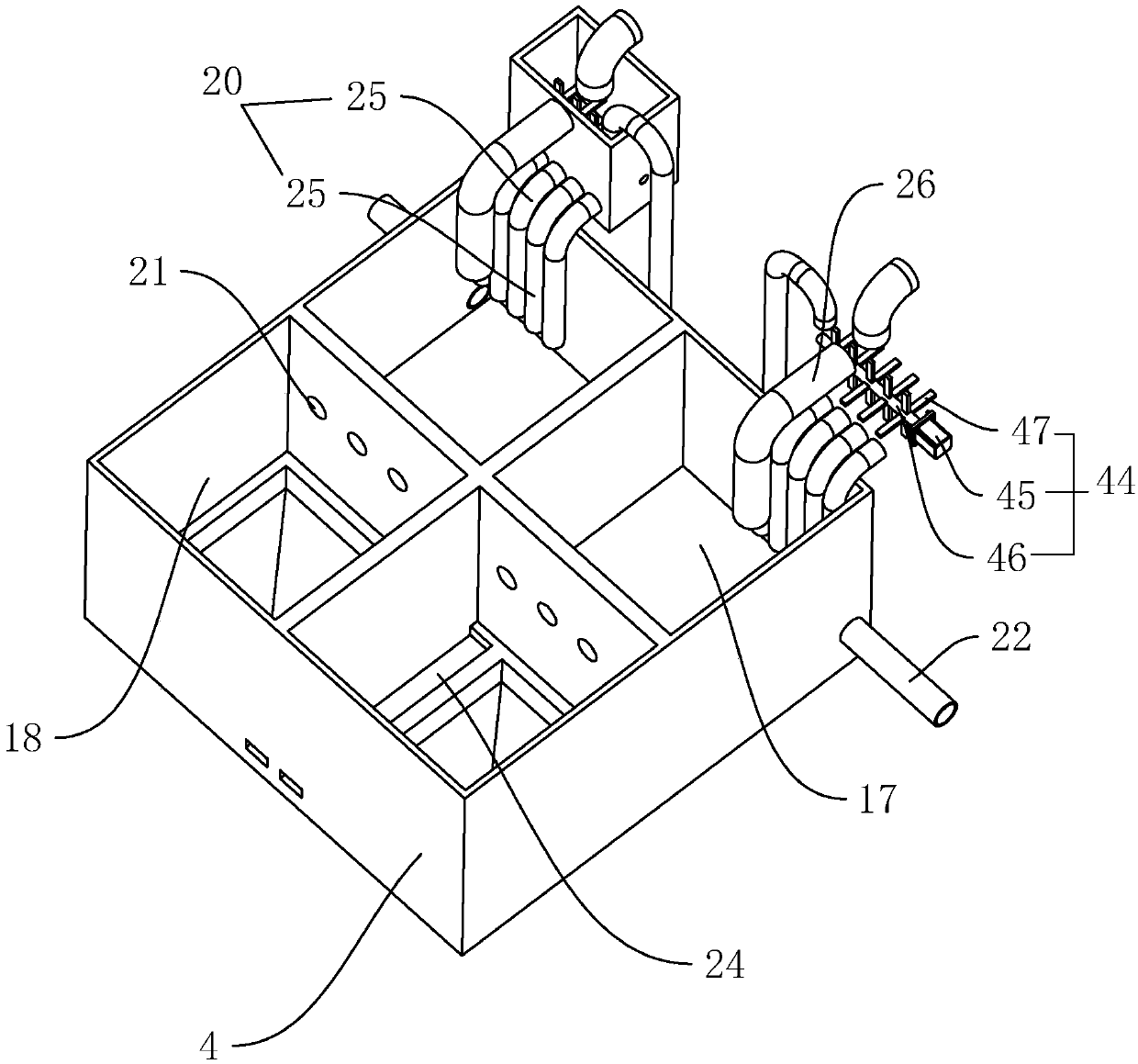

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

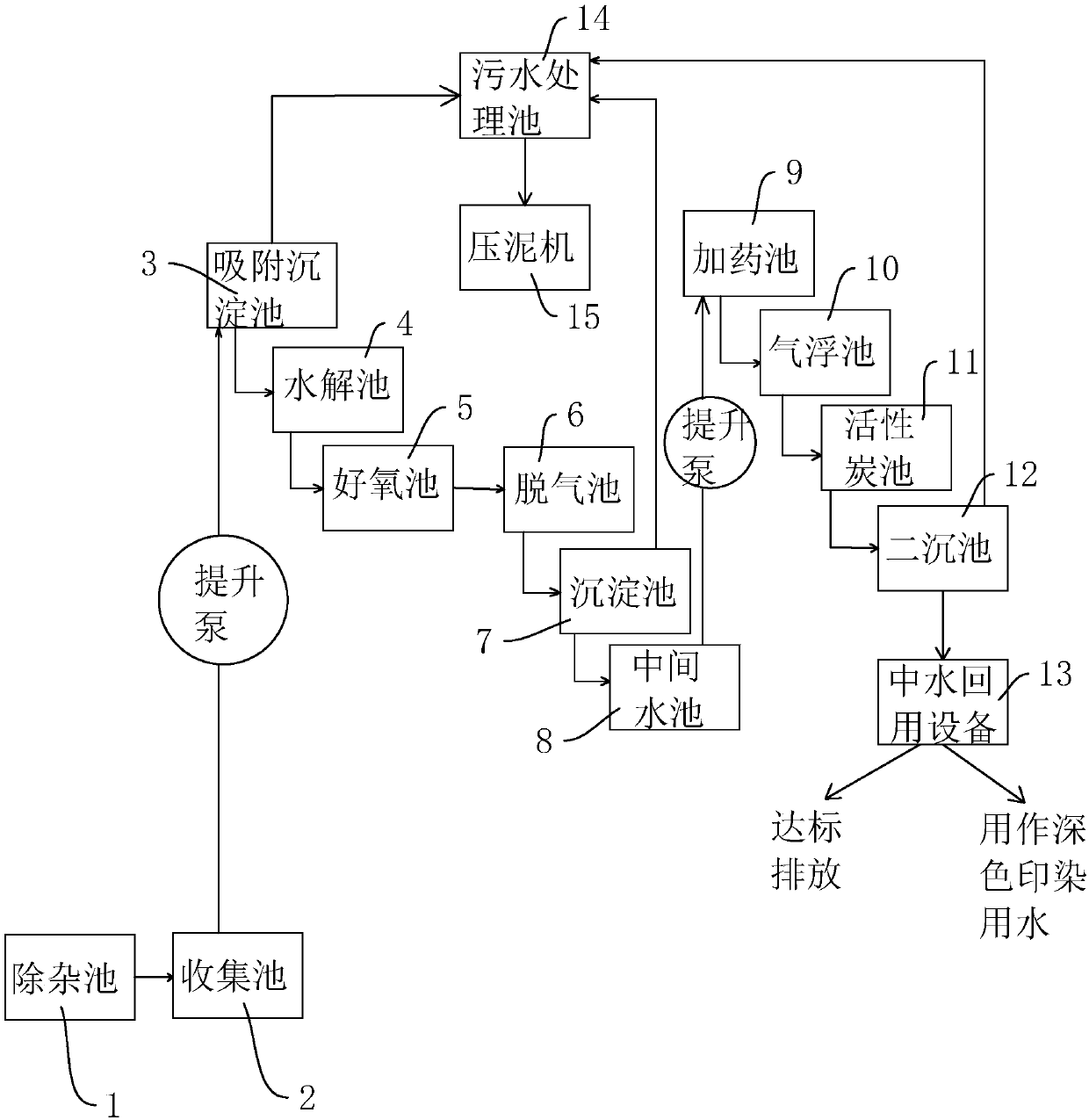

[0045] A sewage treatment system for printing and dyeing, such as figure 1 As shown, its overall process includes:

[0046]The impurity removal pool 1 is equipped with a hair removal machine, and the sewage from the printing and dyeing factory is discharged into the impurity removal pool 1, and the first impurity removal is performed by the hair removal machine, and the fine hairs and larger impurities in the sewage are filtered; Collection pool 2, the sewage after preliminary filtration enters the collection pool 2, the sewage in the impurity removal pool 1 flows into the collection pool 2, and the collection pool 2 is set below the ground; The sewage is sent into the adsorption sedimentation tank 3 located at the highest place through the lifting pump, and the activated sludge is added into the adsorption sedimentation tank 3. The activated sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com