Creep feed for piggies and preparation method of creep feed

A technology of creep feed and piglets, applied in the field of animal husbandry, can solve the problems of growth retardation, decreased feed intake, low feed utilization rate, etc., and achieve the effects of less weaning stress, sweet palatability, and high feed conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

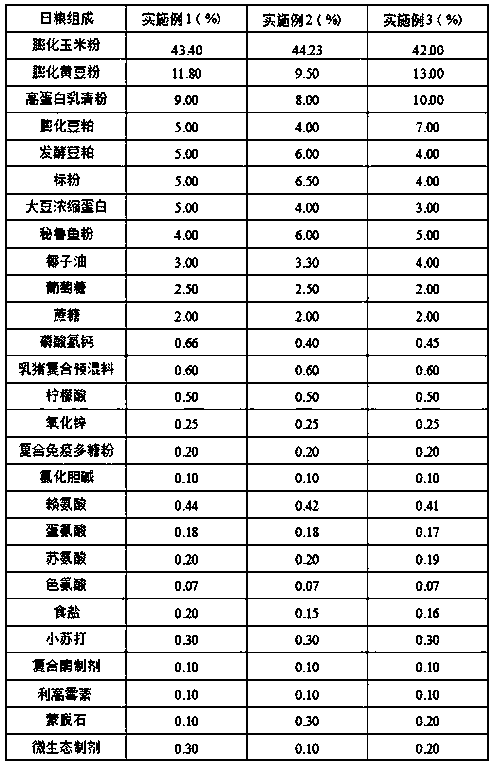

Embodiment 1

[0025] (1) According to the raw material formula in Table 1, salt, calcium hydrogen phosphate, citric acid, choline chloride, suckling pig compound premix, compound immune polysaccharide powder, lysine, methionine, threonine, tryptophan, Zinc oxide, ligomycin, montmorillonite, baking soda, compound enzyme preparation (composed of cellulase, phytase, lipase, β-glucanase and xylanase in a mass ratio of 2:1: 1:2:2 composition) and probiotics are pre-mixed into additive semi-finished products, ready for use;

[0026] (2) Grind extruded corn flour, extruded soybean meal, extruded soybean meal, fermented soybean meal and Peruvian fish meal according to the raw material formula in Table 1. The crushing sieve hole is required to be 1.0mm; the raw material crushing and sieving rate must reach more than 95%; The additive semi-finished product obtained in step (1) is finally added with high-protein whey powder, standard powder, soybean protein concentrate, glucose, coconut oil and sucros...

Embodiment 2

[0029] (1) According to the raw material formula in Table 1, salt, calcium hydrogen phosphate, citric acid, choline chloride, suckling pig compound premix, compound immune polysaccharide powder, lysine, methionine, threonine, tryptophan, Zinc oxide, ligomycin, montmorillonite, baking soda, compound enzyme preparation (composed of cellulase, phytase, lipase, β-glucanase and xylanase in a mass ratio of 3:2: 2:2:3 composition) and the probiotics are pre-mixed into additive semi-finished products, ready for use;

[0030] (2) Grind the extruded corn flour, extruded soybean meal, extruded soybean meal, fermented soybean meal and Peruvian fish meal according to the raw material formula in Table 1. The crushing sieve hole is required to be 1.5mm; the raw material crushing and sieving rate must reach more than 95%; The additive semi-finished product obtained in step (1) is finally added with high-protein whey powder, standard powder, soybean protein concentrate, glucose, coconut oil an...

Embodiment 3

[0033] (1) According to the raw material formula in Table 1, salt, calcium hydrogen phosphate, citric acid, choline chloride, suckling pig compound premix, compound immune polysaccharide powder, lysine, methionine, threonine, tryptophan, Zinc oxide, riscomycin, montmorillonite, baking soda, compound enzyme preparation (composed of cellulase, phytase, lipase, β-glucanase and xylanase in a mass ratio of 3:1: 1:2:2 composition) and probiotics are pre-mixed into additive semi-finished products, ready for use;

[0034](2) Grind extruded corn flour, extruded soybean meal, extruded soybean meal, fermented soybean meal and Peruvian fish meal according to the raw material formula in Table 1. The crushing sieve hole is required to be 1.2mm; the crushing and sieving rate of raw materials should reach more than 95%; The additive semi-finished product obtained in step (1) is finally added with high-protein whey powder, standard powder, soybean protein concentrate, glucose, coconut oil and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com