Preparation method of doping lithium cobalt oxide

A technology of lithium cobaltate and doping elements, which is applied in the field of preparation of modified lithium cobaltate, can solve problems such as different preparation processes, achieve environmental friendliness, simple requirements for calcination equipment, and avoid excessive impurity content of lithium cobaltate products risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

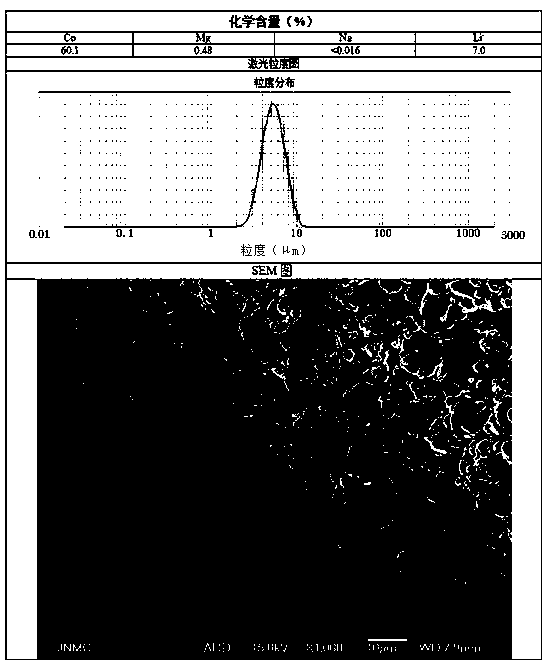

Embodiment 1

[0039] The production steps are the same as above, and the specific parameters in each step are as follows:

[0040] The prepared solution A is a mixed solution of cobalt chloride and lithium chloride, and the cobalt concentration is 1mol / L, and the lithium concentration is 1.2mol / L.

[0041] The prepared B solution is 1.2mol / L ammonium bicarbonate solution.

[0042] Preparation C solution is 4.9g / L MgCl2 solution, and the doping amount of Mg in the final product is 0.5%.

[0043] Prepare solution D as 2.5mol / L sodium hydroxide solution.

[0044] Prepare E solution as 2mol / L hydrogen peroxide solution.

[0045] At the beginning of the synthesis reaction, the A solution, the C solution, the B solution, and the D solution were added to the reactor in parallel, and the reaction was carried out at a stirring intensity of 250 rpm to prepare cobalt hydroxide and lithium carbonate with uniform distribution of doping elements. mixture. The temperature of reaction system is 60 ℃, a...

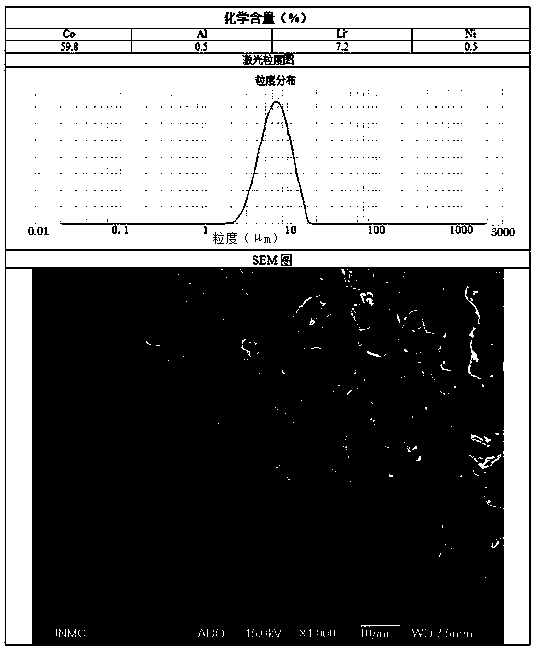

Embodiment 2

[0051] This example is basically the same as Example 1, except that the following adjustment parameters are different:

[0052] The prepared solution A is a mixed solution of cobalt nitrate and lithium nitrate, and the concentration of cobalt is 1.5 mol / L, and the concentration of lithium is 2 mol / L.

[0053] The prepared B solution is 2mol / L ammonium bicarbonate solution.

[0054] Solution C is prepared as 14.7g / L aluminum chloride and nickel nitrate solution, and the doping amount of aluminum and nickel in the final product is about 1% of the final product mass.

[0055] Prepare solution D as 5mol / L sodium hydroxide solution.

[0056] Prepare E solution as 3mol / L hydrogen peroxide solution.

[0057]At the beginning of the synthesis reaction, A solution, C solution, B solution, and D solution were added to the reactor in parallel, and the reaction was carried out at a stirring intensity of 350 rpm to prepare cobalt hydroxide and carbonic acid with uniform distribution of do...

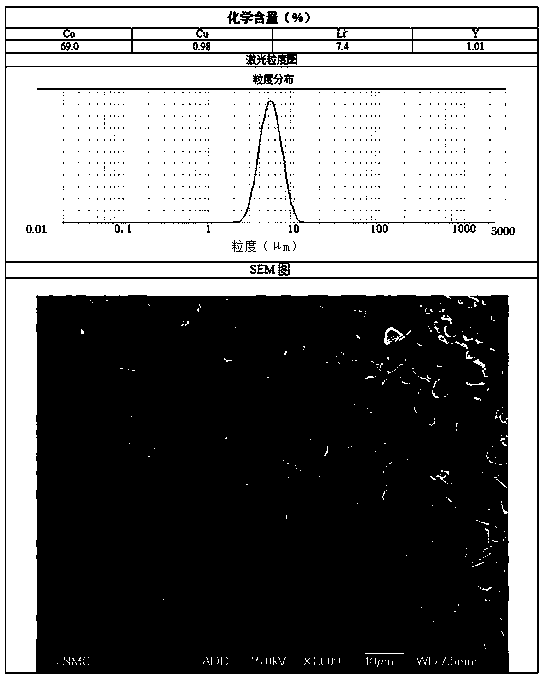

Embodiment 3

[0063] This example is basically the same as Example 1, except that the following adjustment parameters are different:

[0064] The prepared solution A is a mixed solution of cobalt sulfate and lithium chloride, and the cobalt concentration is 2mol / L, and the lithium concentration is 2.5mol / L.

[0065] The prepared B solution is 2.5mol / L ammonium bicarbonate solution.

[0066] Preparation C solution is 39.1g / L copper nitrate and yttrium chloride solution, the doping amount of Cu and Y is about 2% of the final product quality.

[0067] Prepare solution D as 4mol / L sodium hydroxide solution.

[0068] Prepare E solution as 4mol / L hydrogen peroxide solution.

[0069] At the beginning of the synthesis reaction, A solution, C solution, B solution, and D solution were added into the reactor in parallel, and the reaction was carried out at a stirring intensity of 450 rpm. The temperature of the reaction system was 75°C, and the flow rate of the B solution was A solution 0.65 times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com