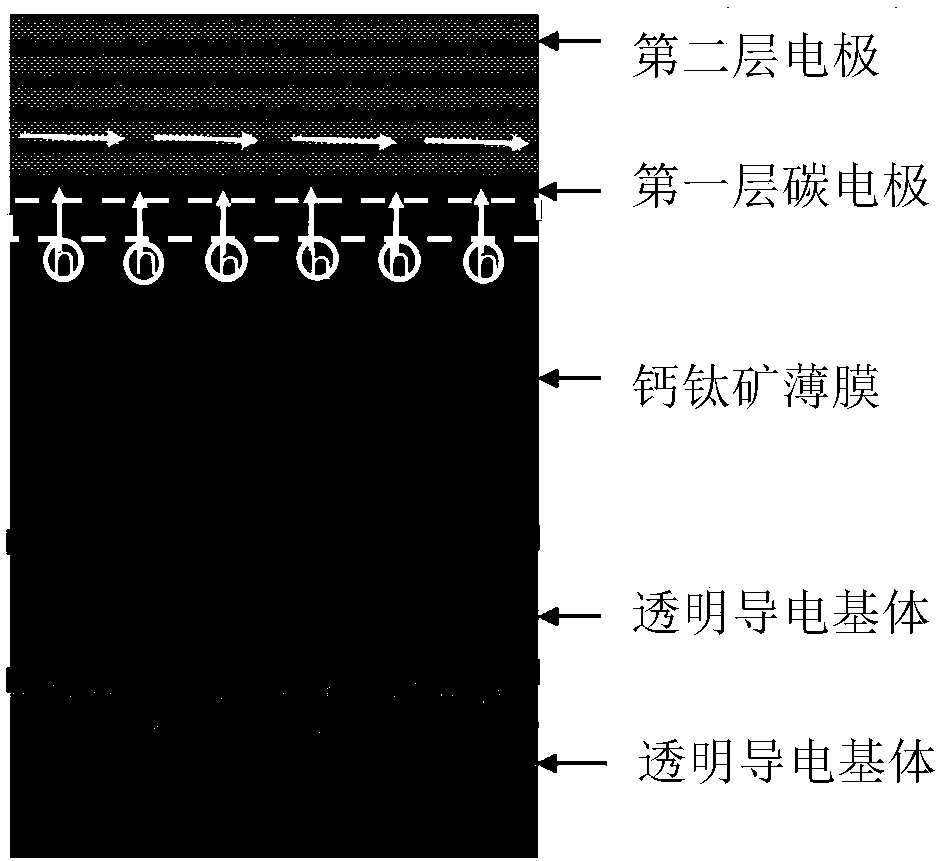

Double-electrode perovskite solar battery and preparation method thereof

A technology for solar cells and double-layer electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of reduced contact area, increased probability of electron and hole recombination in perovskite thin films, and inability to take into account the contact of perovskite thin films and the Carbon electrode conductivity and other problems, to achieve the effect of improving performance and good lateral charge transfer function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. On the ITO (tin-doped indium oxide) substrate, spin-coat TiO 2 Precursor, sintered at 450°C for half an hour to form TiO 2 (electron transport layer);

[0045] 2. In TiO 2 Spin-coat FAPbI on 3 Precursor. Dry to prepare a layer of film, that is, perovskite film;

[0046] 3. Prepare carbon paste A, wherein the conductive fine filler is 50nm carbon black particles, the binder is polyacrylate, and the solvent is chlorobenzene; the mass ratio of conductive fine filler to adhesive is 5:1; the mass of solid phase and solvent The ratio is 1:2.

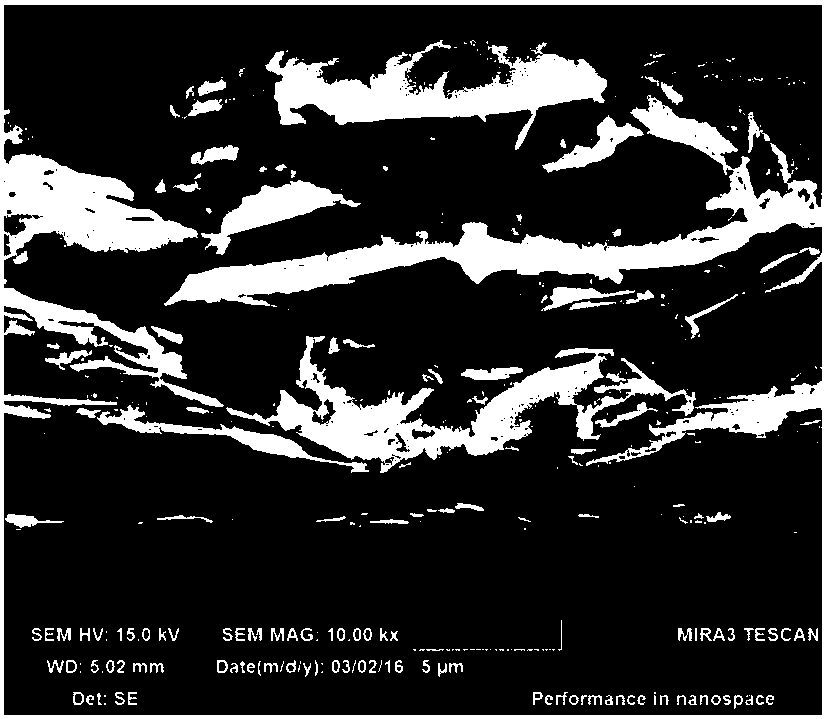

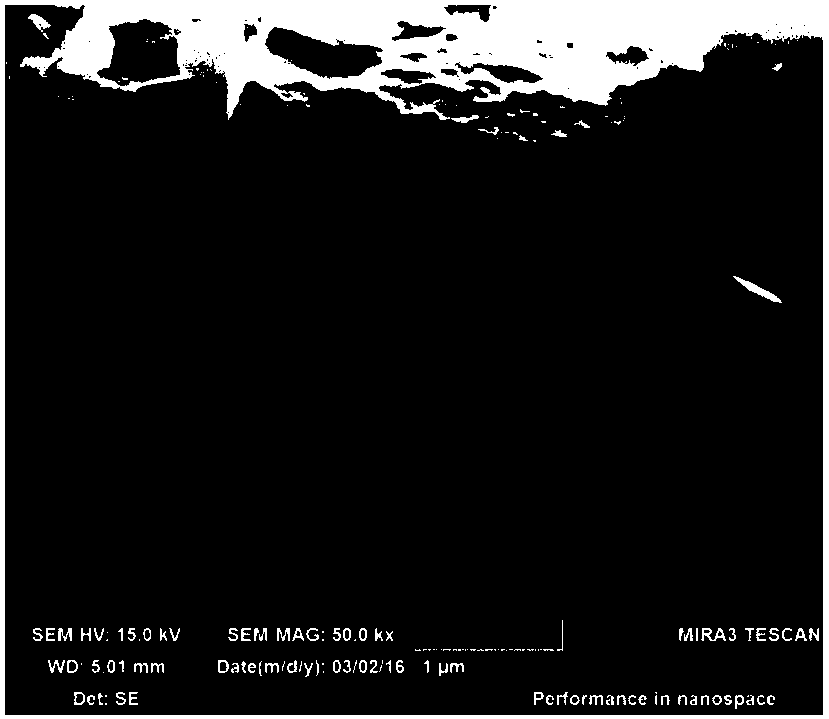

[0047] 4. Scrape a layer of carbon paste A with a thickness of about 3 μm on the perovskite film with a doctor blade method, and then place it on a 100° C. electric heating plate to dry for 10 minutes to obtain the first layer of electrodes.

[0048] 5. On the first layer of electrodes, scrape a layer of directly purchased commercial carbon paste with a thickness of about 15 μm with a thickness of about 15 μm, and then place it...

Embodiment 2

[0051] 1. On the FTO (fluorine-doped tin oxide) substrate, spin-coat SnO 2 Precursor, sintered at 450°C for half an hour to form TiO 2 (electron transport layer);

[0052] 2. On SnO 2 Spin-coat MAPbI on 3 (methylammonium lead iodide) precursor. Dry to prepare a layer of film, that is, perovskite film;

[0053] 3. Prepare carbon paste A, wherein the conductive fine filler is 80nm carbon microspheres, the binder is polyacrylic resin, and the solvent is propylene glycol acetate; the mass ratio of conductive fine filler to binder is 4:1; solid phase and The mass ratio of solvents is 2:1.

[0054] 4. Scrape a layer of carbon paste A with a thickness of about 15 μm on the perovskite film with a scraper method, place it on the first layer of electrodes, and then place it at a temperature of 100 ° C for 15 minutes, and cover it with a layer of graphite paper as the second layer. Layer carbon electrodes, that is, perovskite solar cells made of double-layer electrodes.

[0055] T...

Embodiment 3

[0057] 1. On the FTO substrate, sputter 50nm ZnO film to form TiO 2 (electron transport layer);

[0058] 2. Spin-coating MAPbI on ZnO 3 Precursor. Dry to prepare a layer of film, that is, perovskite film;

[0059] 3. Prepare carbon paste A, wherein the conductive fine filler is carbon fiber with a diameter of 30nm, the binder is polyacrylic acid resin, and the solvent is propylene glycol acetate; the mass ratio of conductive fine filler to binder is 6:1; solid phase and solvent The mass ratio is 1:1.

[0060] 4. Scrape a layer of carbon paste A with a thickness of about 5 μm on the perovskite film with a doctor blade method, and then place it on a 100° C. electric heating plate to dry for 15 minutes to obtain the first layer of electrodes.

[0061] 5. On the first layer of electrodes, use a screen printing layer of commercial conductive silver paste (Saiya paste 01L-2200) with a thickness of about 10 μm, and dry at 80°C for 20 minutes to form a perovskite solar cell with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com