A kind of production method of tinned copper powder

A production method and technology of tinned copper, applied in liquid chemical plating, transportation and packaging, coating and other directions, can solve the problems of poor compactness, difficult reaction control, complicated operation, etc., and achieve compact structure, convenient operation and simplified process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

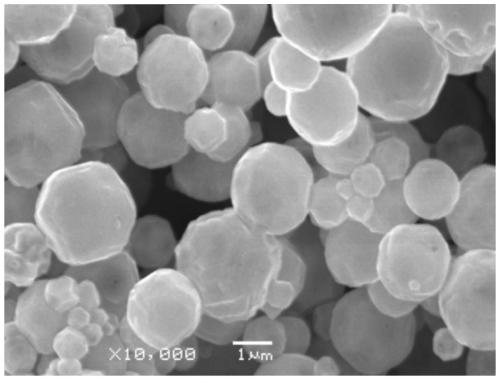

[0050] A production method of tinned copper powder, comprising the following steps:

[0051] 1) Copper powder cleaning: Take 112g of copper powder produced by the company, add 20ml of 5% dilute sulfuric acid and 0.5% detergent-6503 (3g), ultrasonically stir for 15min, filter and clean, and filter out the water for later use;

[0052] 2) Preparation of tin salt solution: add 12g sodium dodecylsulfonate, 80g diethylenetriaminepentaacetic acid, 40g triethylenetetramine, 13g PVP (polyvinylpyrrolidone), 15.6g stannous sulfate in 8L reverse osmosis water, Stir evenly with 500ml alcohol to obtain tin salt stock solution;

[0053] 3) Preparation of the reaction stock solution: then add the cleaned copper powder to the tin salt solution, ultrasonically disperse for 15 minutes, and mix evenly to obtain the reaction stock solution;

[0054] 4) Powder coating: Add 46g of hydrazine hydrate to a 1L beaker and stir well to obtain a reducing agent solution; then drop the reducing agent solut...

Embodiment 2

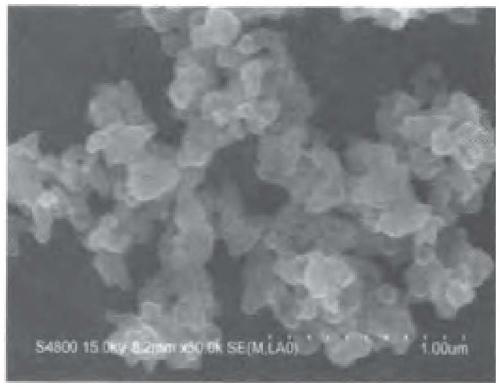

[0057] A production method of tinned copper powder, comprising the following steps:

[0058] 1) Cleaning of copper powder: Take 112g of copper powder produced by the company, add 20ml of 5% dilute sulfuric acid and 0.5% of OP-10 (3g), ultrasonically stir for 15 minutes, filter and clean, and filter out the water for later use;

[0059] 2) Preparation of tin salt solution: add 12g of tartaric acid, 80g of ethylenediaminetetraacetic acid, 40g of ethylenediamine, 13g of polyethylene glycol, and 15.6g of stannous sulfate into 8L of reverse osmosis water, and stir evenly with 500ml of alcohol to obtain tin salt stock solution;

[0060] 3) Preparation of the reaction stock solution: then add the cleaned copper powder to the tin salt solution, ultrasonically disperse for 25 minutes, and mix evenly to obtain the reaction stock solution;

[0061] 4) Powder coating: Add 46g of 1-propanol to a 1L beaker and stir well to obtain a reducing agent solution; then drop the reducing agent solu...

Embodiment 3

[0064] A production method of tinned copper powder, comprising the following steps:

[0065] 1) Cleaning of copper powder: Take 112g of copper powder produced by the company, add 20ml of 5% dilute sulfuric acid and 3g of 0.5% sodium lauryl sulfate, stir ultrasonically for 15min, filter and clean, and filter out the water for later use;

[0066] 2) Preparation of tin salt solution: Add 40 g of triethylenetetramine, 13 g of polyacrylic acid, and 15.6 g of stannous sulfate into 8 L of reverse osmosis water, and stir evenly with 500 ml of alcohol to obtain a tin salt stock solution;

[0067] 3) Preparation of the reaction stock solution: then add the cleaned copper powder to the tin salt solution, ultrasonically disperse for 15 minutes, and mix evenly to obtain the reaction stock solution;

[0068] 4) Powder coating: Add 46g of ethylene glycol to a 1L beaker and stir well to obtain a reducing agent solution; then drop the reducing agent solution into a 5L reaction stock solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com