Amino acid aldehyde Schiff base feed additive and feed

A technology of amino acid aldehyde Schiff base and amino acid aldehyde Schiff, applied in animal feed, additional food elements, applications, etc., can solve the problems of easy oxidation, volatilization, and polymerization of aldehydes, so as to promote animal growth, Stable properties and the effect of preventing feed mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In a 2000L reaction kettle, add 1500kg of deionized water and 146kg of lysine, stir and dissolve quickly, pump 132kg of 99% cinnamaldehyde (molar ratio 1:1), react for 60 minutes, cool and crystallize, and centrifuge to obtain light yellow lysine. Amino acid cinnamaldehyde lysine Schiff base 260kg, detected by liquid chromatography (standard samples purchased from the United States sigma company) cinnamaldehyde lysine Schiff base content: 94.3%, yield 94.3% or more.

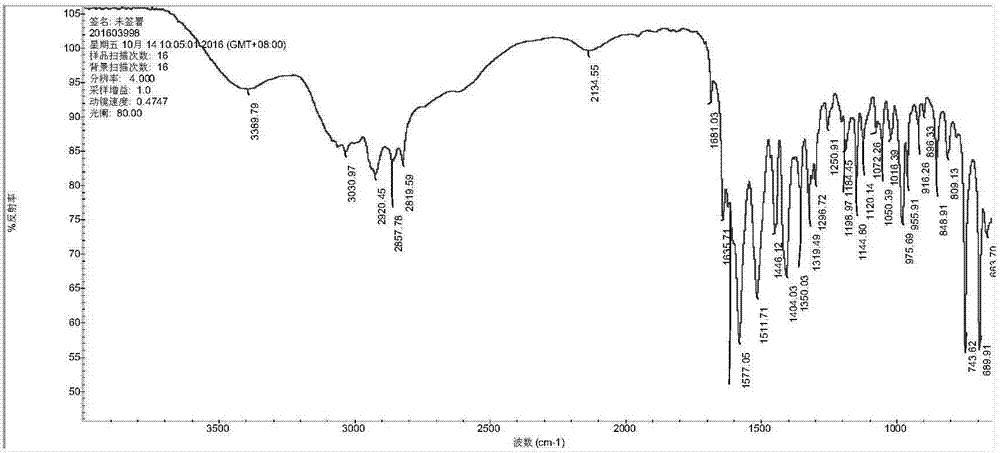

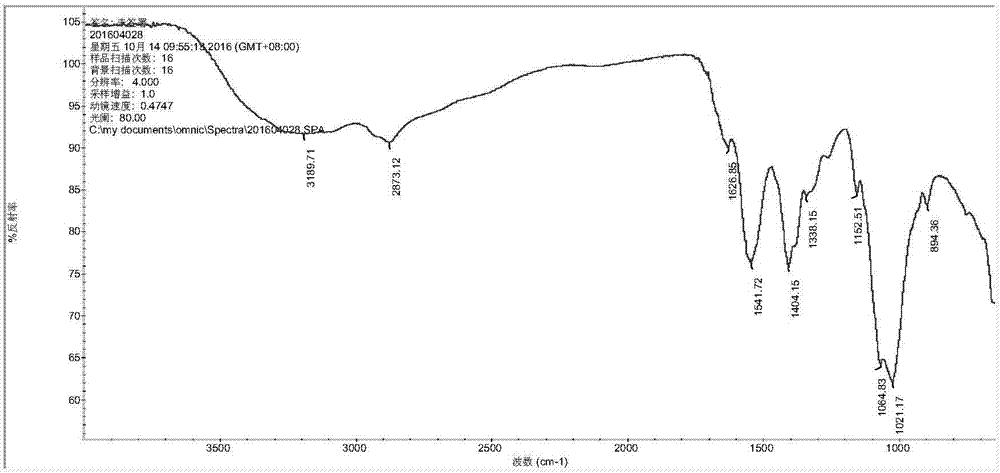

[0051] Infrared spectrum detection of cinnamaldehyde and cinnamaldehyde lysine Schiff base, the results are shown in figure 1 and figure 2 , figure 1 is the infrared spectrum of cinnamaldehyde lysine Schiff base, figure 2 Infrared spectrum of cinnamaldehyde.

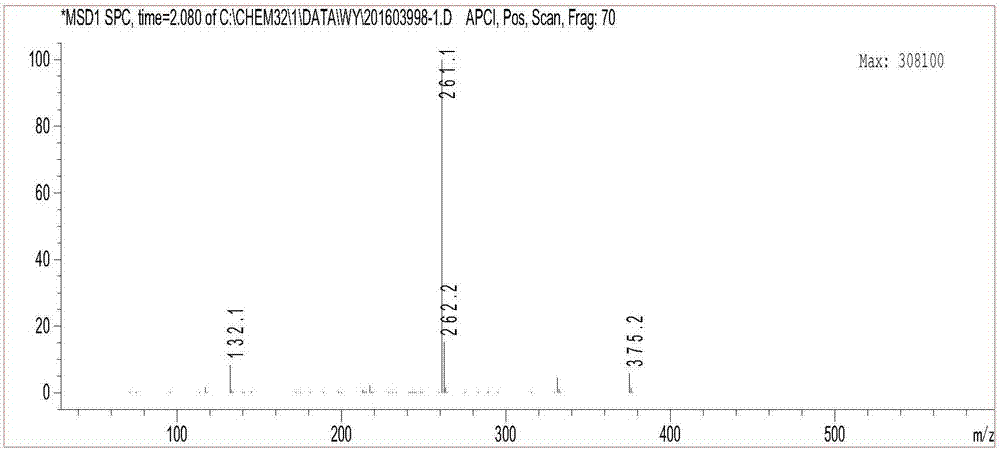

[0052] And the cinnamaldehyde lysine Schiff base is carried out to gas chromatography-mass chromatography detection, the results are shown in image 3 , image 3 It is the GC-MS spectrum of cinnamaldehyde lysine Schiff base. Depend on image...

Embodiment 2

[0054] The 260kg cinnamaldehyde lysine Schiff base and maltodextrin 50kg mixed granulation that embodiment 1 produces, contain the granule 310kg of cinnamaldehyde lysine Schiff base, use 8% polyacrylic acid resin in coating vulcanized bed Carry out coating with 16% monoglyceride stearate, 2% polyethylene glycol ethanol solution, three kinds of coating materials allow particle weight gain 6%, obtain coating cinnamaldehyde lysine Schiff base particle 328kg, menses The content of cinnamaldehyde lysine Schiff base detected by phase chromatography (the standard sample was purchased from Sigma, USA) was 74.7%.

Embodiment 3

[0056] In a 2000L reactor, add 1500kg of deionized water and 146kg of lysine, stir and dissolve quickly, pump 132kg of 99% cinnamaldehyde (molar ratio 1:1), and react for 60 minutes to obtain lysine Schiff containing cinnamaldehyde The reaction solution of alkali, wherein, contains cinnamaldehyde lysine Schiff base 260kg in the described reaction solution.

[0057] Slowly pump 300 kg of an aqueous solution containing 125 kg of copper sulfate pentahydrate into the cinnamaldehyde lysine Schiff base reaction solution prepared above, maintain pH 7.2-7.5, and react for 1.5 hours. A large amount of green precipitates are formed, which are centrifuged and dried to obtain 300kg cinnamaldehyde lysine Schiff base copper compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com