High performance magnesium matrix composite based on laser 3D printing forming and preparation method thereof

A technology of 3D printing and composite materials, which is applied in the field of high-performance magnesium-based composite materials and its preparation, and can solve problems affecting powder spreading performance, high saturated vapor pressure, and affecting powder spreading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

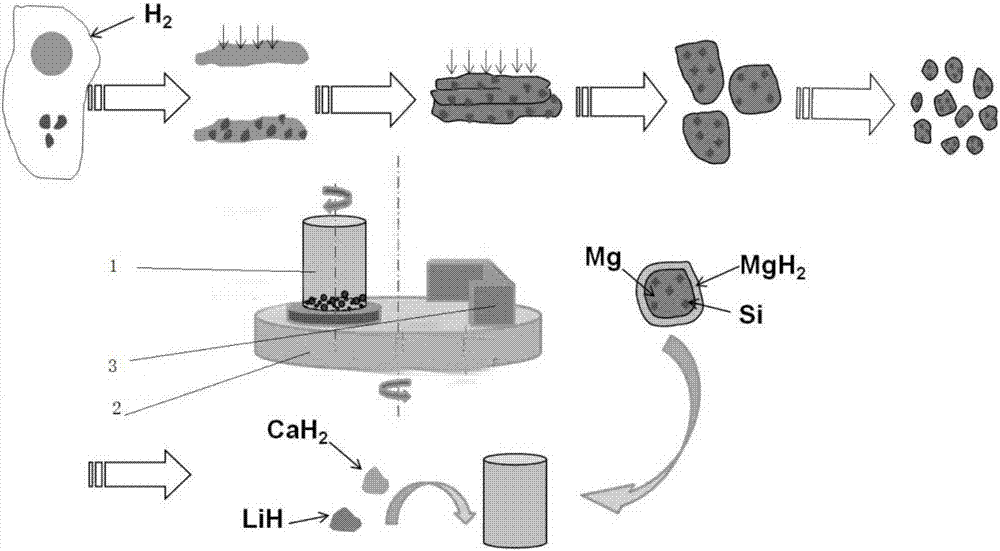

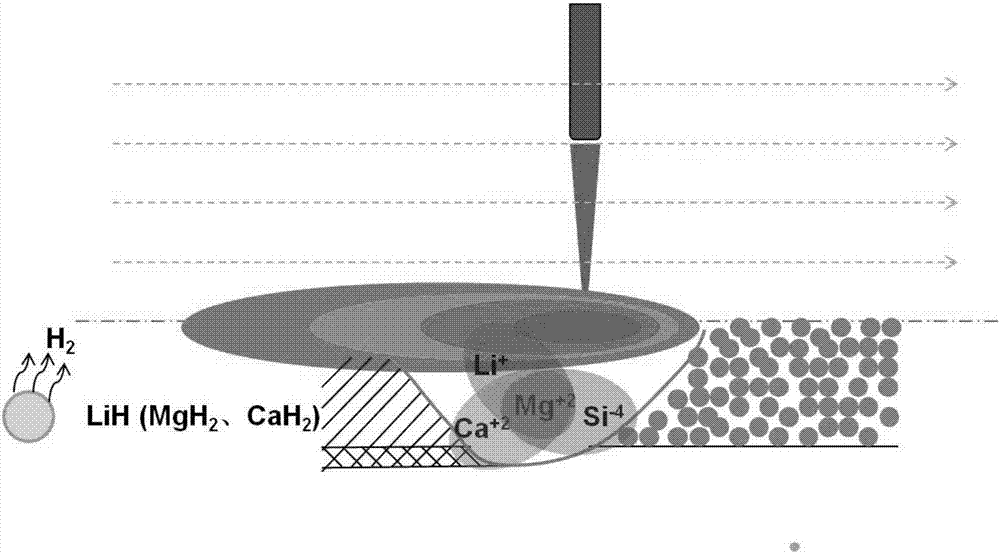

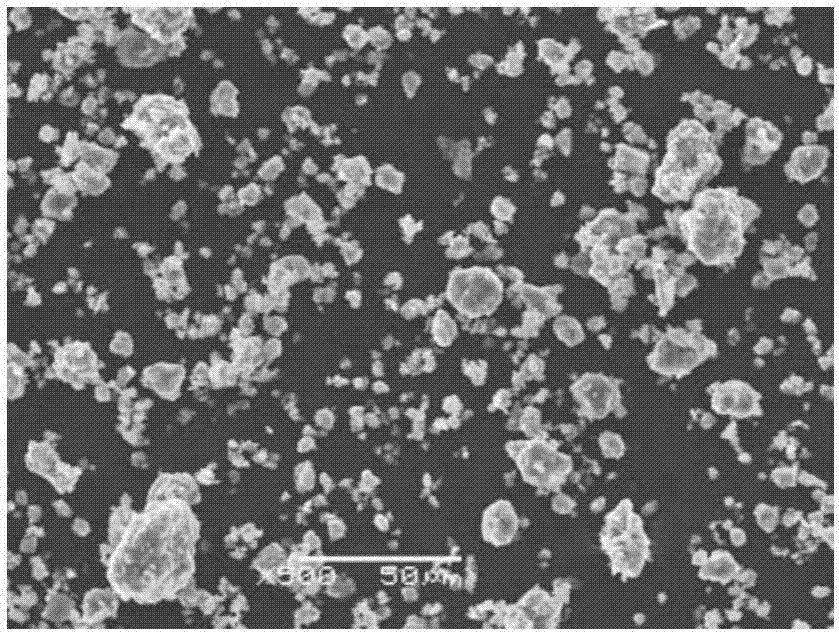

[0053] The present invention is a high-performance magnesium-based composite material based on laser 3D printing and its preparation method. The preparation process of the magnesium-based composite material includes two stages of mechanical ball milling and powder mixing and laser 3D printing forming and curing:

[0054] (i) Mechanical ball milling: Weigh 2wt.% elemental silicon particles (average particle size of 3 microns) and magnesium matrix powder (average particle size of 20 microns) for proportioning, and place them in a ball mill for mechanical high-energy ball milling. Before the ball milling, the ball mill tank was continuously evacuated and the residual air was exhausted with argon, and then hydrogen gas was introduced into the tank, and the air pressure was controlled at 0.5 Mpa. The ball milling time is set to 8h, the ball milling speed is 250r / min, the ball-to-material ratio in the ball milling process is 8:1, every 15 minutes of ball milling, cooling for 10 minut...

Embodiment 2

[0059] The present invention is a magnesium-based composite material formed based on laser 3D printing. The preparation process of the magnesium-based composite material includes two stages of mechanical ball milling and powder mixing and laser 3D printing forming and curing:

[0060] (i) Mechanical ball milling: Weigh 4wt.% elemental silicon particles (average particle size 5 microns) and magnesium matrix powder (average particle size 30 microns) for proportioning, and place them in a ball mill for mechanical high-energy ball milling. Before the ball milling, the ball mill tank was continuously evacuated and the residual air was exhausted with argon, and then hydrogen gas was introduced into the tank, and the air pressure was controlled at 0.5 Mpa. The ball milling time is set to 10h, the ball milling speed is 300r / min, the ball to material ratio in the ball milling process is 8:1, every 15 minutes of ball milling, cooling for 10 minutes. Weigh 1.5wt.% calcium hydride powder ...

Embodiment 3

[0065] The present invention is a magnesium-based composite material formed based on laser 3D printing. The preparation process of the magnesium-based composite material includes two stages of mechanical ball milling and powder mixing and laser 3D printing forming and curing:

[0066] (i) Mixing powder by mechanical ball milling: weigh 5wt.% elemental silicon particles (average particle size of 6 microns) and magnesium matrix powder (average particle size of 15 microns) for proportioning, and place them in a ball mill for mechanical high-energy ball milling. Before the ball milling, the ball mill tank was continuously evacuated and the residual air was exhausted with argon, and then hydrogen gas was introduced into the tank, and the air pressure was controlled at 0.5 Mpa. The ball milling time is set to 5h, the ball milling speed is 350r / min, the ball-to-material ratio in the ball milling process is 8:1, every 15 minutes of ball milling, cooling for 10 minutes. Weigh 2wt.% cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com