Surface active agent containing selenous anions and preparation method and application thereof

A technology of surfactants and anions, applied in the direction of surface active detergent compositions, surface active non-soap compounds and cleaning compositions, chemical instruments and methods, etc., can solve problems such as high safety risks, toxic and side effects, and achieve aquatic organisms Low acute toxicity, low cytotoxicity and skin irritation, excellent free radical scavenging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

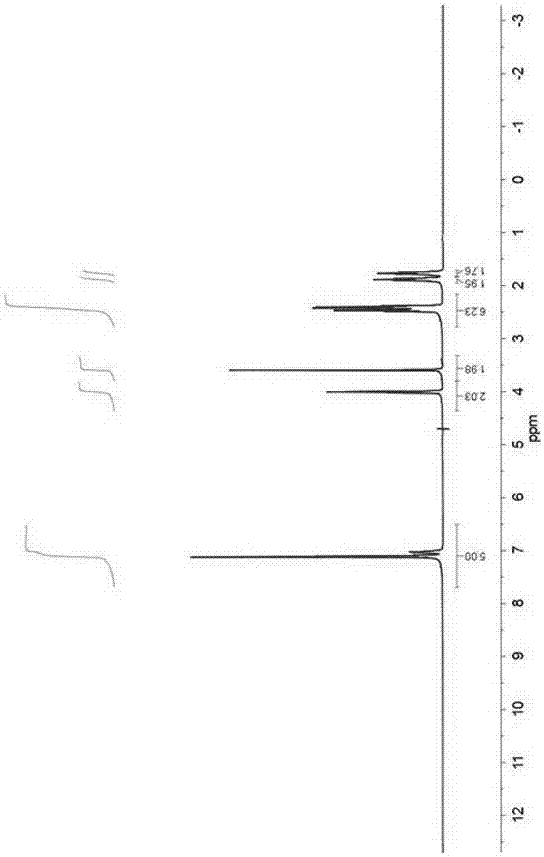

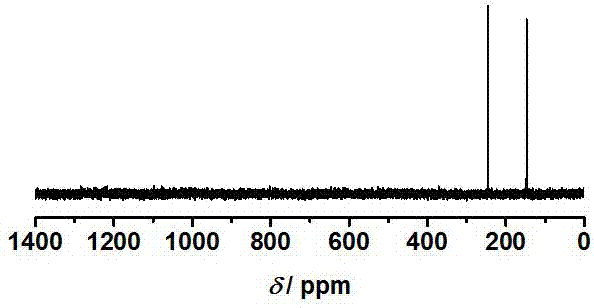

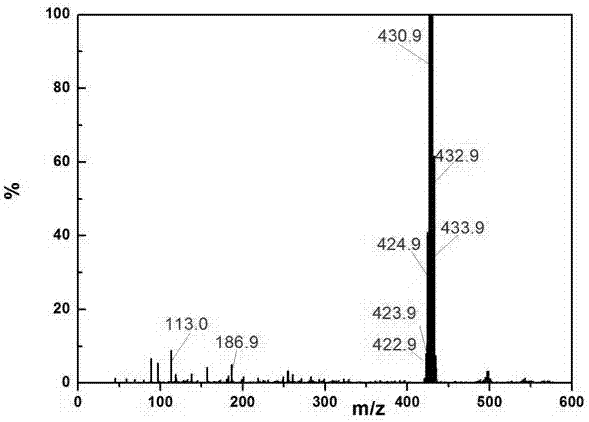

[0042] The preparation method of the diselenium-containing anionic surfactant of this embodiment includes the following steps:

[0043] (1) Preparation of benzylselenyl chloroethane: Dissolve 4.0 g of dibenzyl diselenide (0.012 mol) in 35 mL of tetrahydrofuran under nitrogen protection, and add 2.2 g of sodium borohydride (0.048 mol) in an ice-water bath. ) And reacted in an ice-water bath for 30 minutes, and then add the bromodichloroethane dissolved in tetrahydrofuran to the above system according to the molar ratio of short-chain chlorobromoalkane: dibenzyl diselenide 1:2.1 After reacting in an ice-water bath for 0.5 hours, the organic phase was extracted with dichloromethane. After dehydration and evaporation of the solvent, it was applied to a silica gel column and eluted with a mixed solvent of ethyl acetate and petroleum ether at a volume ratio of 1:10 to obtain benzyl selenium. Benzyl ethane chloro-yellow liquid, the yield of benzylselenyl chloroethane is 92.8%;

[0044] (...

Embodiment 2

[0049] The preparation method of the diselenium-containing anionic surfactant of this embodiment includes the following steps:

[0050] (1) Preparation of benzylselenyl chloropropane: Dissolve 4.0 g of dibenzyl diselenide (0.012 mol) in 35 mL of tetrahydrofuran under the protection of nitrogen, and add 2.2 g of sodium borohydride (0.048 mol) dropwise in an ice-water bath. After reacting in an ice-water bath for 30 minutes, add bromotrichloropropane previously dissolved in tetrahydrofuran according to the molar ratio of short-chain chlorobromoalkane: dibenzyl diselenide 1:2.1 to the above system. After 0.5 hours of reaction in an ice-water bath, the organic phase was extracted with dichloromethane. After dehydration and evaporation of the solvent, it was applied to a silica gel column and eluted with a mixed solvent of ethyl acetate and petroleum ether at a volume ratio of 1:10 to obtain benzylselenoethane Chloro-yellow liquid, the yield of benzylselenyl chloropropane is 94.2%;

[...

Embodiment 3

[0056] The preparation method of the diselenium-containing anionic surfactant of this embodiment includes the following steps:

[0057] (1) Preparation of benzylselenyl chlorobutane: Dissolve 4.0 g of dibenzyl diselenide (0.012 mol) in 35 mL of tetrahydrofuran under the protection of nitrogen, and add 2.2 g of sodium borohydride (0.048 mol) in an ice-water bath. ) And reacted in an ice-water bath for 30 minutes, and then add bromotetrachlorobutane dissolved in tetrahydrofuran to the above system according to the molar ratio of short-chain chlorobromoalkane: dibenzyl diselenide 1:2.1 After reacting in an ice-water bath for 0.5 hours, the organic phase was extracted with dichloromethane. After dehydration and evaporation of the solvent, it was applied to a silica gel column and eluted with a mixed solvent of ethyl acetate and petroleum ether at a volume ratio of 1:10 to obtain benzyl selenium. Ethane chloro-yellow liquid, the yield of benzylselenyl chlorobutane is 93.7%;

[0058] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com