Preparation method of polypropene plastic for high-toughness instrument panel

A polypropylene plastic and instrument panel technology, which is applied in the field of instrument panel, can solve the problems that the toughness cannot meet the demand, etc., and achieve the effects of good heat resistance and aging resistance, large interlayer spacing, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

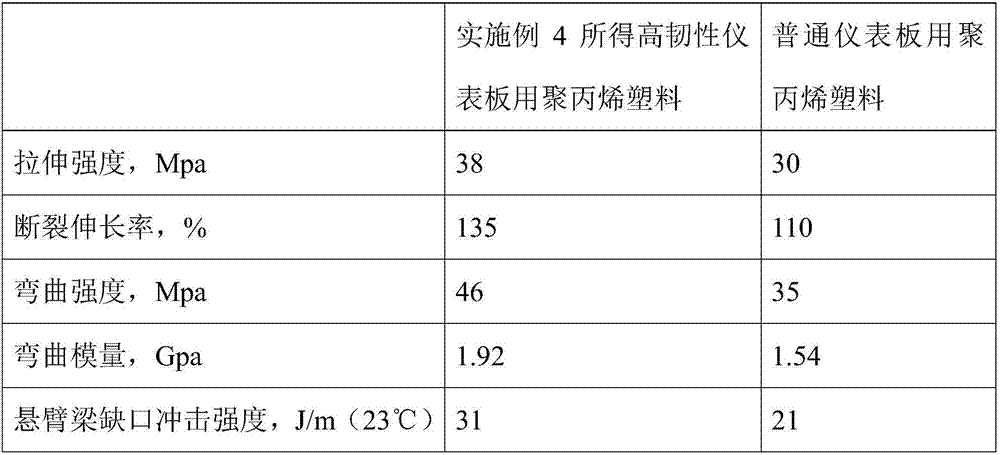

Examples

Embodiment 1

[0016] A preparation method of polypropylene plastic for high-toughness instrument panels, comprising the following steps: 70kg of random copolymer polypropylene, 60kg of nitrile silicone rubber, 15kg of methyl methacrylate-butadiene-styrene terpolymer, 4kg of 1 , 1-bis-(tert-butylperoxy)cyclohexane, 10kg calcium oxide complex, 14kg lignin fiber, 6kg nano bentonite, 18kg heavy calcium carbonate, 6kg coal gangue powder, 10kg mica powder, 1kg antioxidant ODA , 2kg of antioxidant BLE, 3kg of pine tar, 8kg of oxidized polyethylene wax, 4kg of coumarone resin, stirred for 25min, stirring speed of 1800r / min, and then put into a twin-screw extruder with a length-to-diameter ratio of 35:1 Pellet, extruder temperature setting: zone one 175℃, zone two 255℃, zone three 185℃, zone four 255℃, zone five 195℃, zone six 255℃, zone seven 205℃, twin screw extruder speed is 500r / min to obtain polypropylene plastic for high-toughness instrument panels.

[0017] The calcium oxide compound is prepare...

Embodiment 2

[0019] A preparation method of polypropylene plastic for high-toughness instrument panels, including the following steps: 90kg of random copolymer polypropylene, 40kg of nitrile silicone rubber, 25kg of methyl methacrylate-butadiene-styrene terpolymer, 2kg of 1 ,1-Bis-(tert-butylperoxy)cyclohexane, 20kg calcium oxide complex, 8kg lignin fiber, 14kg nano bentonite, 8kg heavy calcium carbonate, 14kg coal gangue powder, 6kg mica powder, 2kg antioxidant ODA , 1kg of antioxidant BLE, 6kg of pine tar, 4kg of oxidized polyethylene wax, 8kg of coumarone resin, stirred for 15min at a stirring speed of 2200r / min, and then put into a twin-screw extruder with a length-to-diameter ratio of 25:1 Pellet, extruder temperature setting: zone one 255℃, zone two 175℃, zone three 255℃, zone four 185℃, zone five 255℃, zone six 195℃, zone seven 255℃, twin screw extruder speed is 350r / min to obtain polypropylene plastic for high tenacity instrument panel.

[0020] The calcium oxide compound is prepared...

Embodiment 3

[0022] A preparation method of polypropylene plastic for high-toughness instrument panels, including the following steps: 85kg of random copolymer polypropylene, 45kg of nitrile silicone rubber, 22kg of methyl methacrylate-butadiene-styrene terpolymer, 2.5 kg1,1-bis-(tert-butylperoxy)cyclohexane, 18kg calcium oxide compound, 10kg lignin fiber, 12kg nano bentonite, 10kg heavy calcium carbonate, 12kg coal gangue powder, 7kg mica powder, 1.8kg anti-aging ODA, 1.3kg antioxidant BLE, 5kg pine tar, 5kg oxidized polyethylene wax, 7kg coumarone resin, stir for 18min at a stirring speed of 2000r / min, and then put it into a twin-screw extruder with an aspect ratio of 28:1 Extrusion granulation, temperature setting of extruder: 220℃ in one zone, 180℃ in two zone, 230℃ in three zone, 190℃ in zone four, 240℃ in zone five, 200℃ in zone six, 250℃ in zone seven, twin screw extrusion The machine speed is 450r / min, and the polypropylene plastic for high-toughness instrument panel is obtained.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com