A kind of conductive non-woven fabric and preparation method thereof

A non-woven fabric and fiber web technology, applied in non-woven fabrics, textiles and papermaking, plant fibers, etc., can solve the problems of single function of conductive non-woven fabrics, lack of electrical conductivity, complex production process, etc., to change the preparation performance Problems, low processing cost, and solving the effect of complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

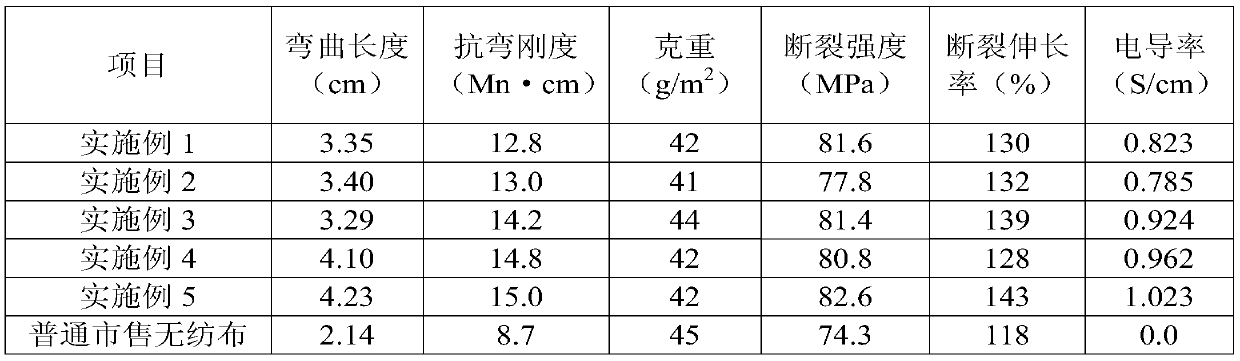

Examples

Embodiment 1

[0036] A conductive non-woven fabric

[0037] Raw material and ingredient composition: (unit: g)

[0038]200g polypropylene fiber, 200g seaweed fiber, 300g composite water-based polyurethane dispersion, 80g methyl hydrogen polysiloxane, 30g nano-titanium dioxide, 30g nano-copper, 10g vinyltriethoxysilane, 10g ethyl p-hydroxybenzoate, Dioctyl adipate 20g, acrylonitrile-butadiene-styrene copolymer 20g.

[0039] Prepared by:

[0040] S10: Preparation of composite water-based polyurethane dispersion: Add the above weight of methylhydrogenpolysiloxane to the above weight of vinyltriethoxysilane and shake in the oscillator for 15s, filter the shaken solution and add the above weight Nano-titanium dioxide and nano-copper are kept at a temperature of 65°C for 10 minutes, and after stirring evenly, they are added to the water-based polyurethane dispersion of the above weight to obtain a composite water-based polyurethane dispersion;

[0041] S20: Fiber web preparation: Weigh the sea...

Embodiment 2

[0044] A conductive non-woven fabric

[0045] Raw material and ingredient composition: (unit: g)

[0046] 300g polypropylene fiber, 300g seaweed fiber, 400g composite water-based polyurethane dispersion, 100g methylhydrogen polysiloxane, 80g nano-titanium dioxide, 80g nano-copper, 40g vinyltrimethoxysilane, 60g ethyl p-hydroxybenzoate, Epoxidized soybean oil 50g, methyl methacrylate-butadiene-styrene copolymer 40g.

[0047] Prepared by:

[0048] S10: Preparation of composite water-based polyurethane dispersion: Add the above weight of methylhydrogenpolysiloxane to the above weight of vinyltrimethoxysilane and shake it in a shaker for 20s, filter the shaken solution and add the above weight The nano-titanium dioxide and nano-copper are kept at a temperature of 80° C. for 15 minutes, and after stirring evenly, they are added to the water-based polyurethane dispersion of the above weight to obtain a composite water-based polyurethane dispersion;

[0049] S20: Fiber web prepara...

Embodiment 3

[0052] A conductive non-woven fabric

[0053] Raw material and ingredient composition: (unit: g)

[0054] 220g polypropylene fiber, 220g seaweed fiber, 320g composite water-based polyurethane dispersion, 80g methylhydrogen polysiloxane, 40g nano-titanium dioxide, 40g nano-copper, 20g vinyltrisilane, 20g ethyl p-hydroxybenzoate, hexadiene Acrylic acid propylene glycol polyester 20g, acrylonitrile-butadiene-styrene copolymer 10g, methyl methacrylate-butadiene-styrene polymer copolymer 10g.

[0055] Prepared by:

[0056] S10: Preparation of composite water-based polyurethane dispersion: Add the above weight of methylhydrogenpolysiloxane to the above weight of vinyltrisilane and shake it in a shaker for 17s, filter the solution after shaking and add the above weight of nano-titanium dioxide and nano-copper, kept at a temperature of 68° C. for 12 minutes, stirred evenly, and added to the water-based polyurethane dispersion of the above weight to obtain a composite water-based pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com