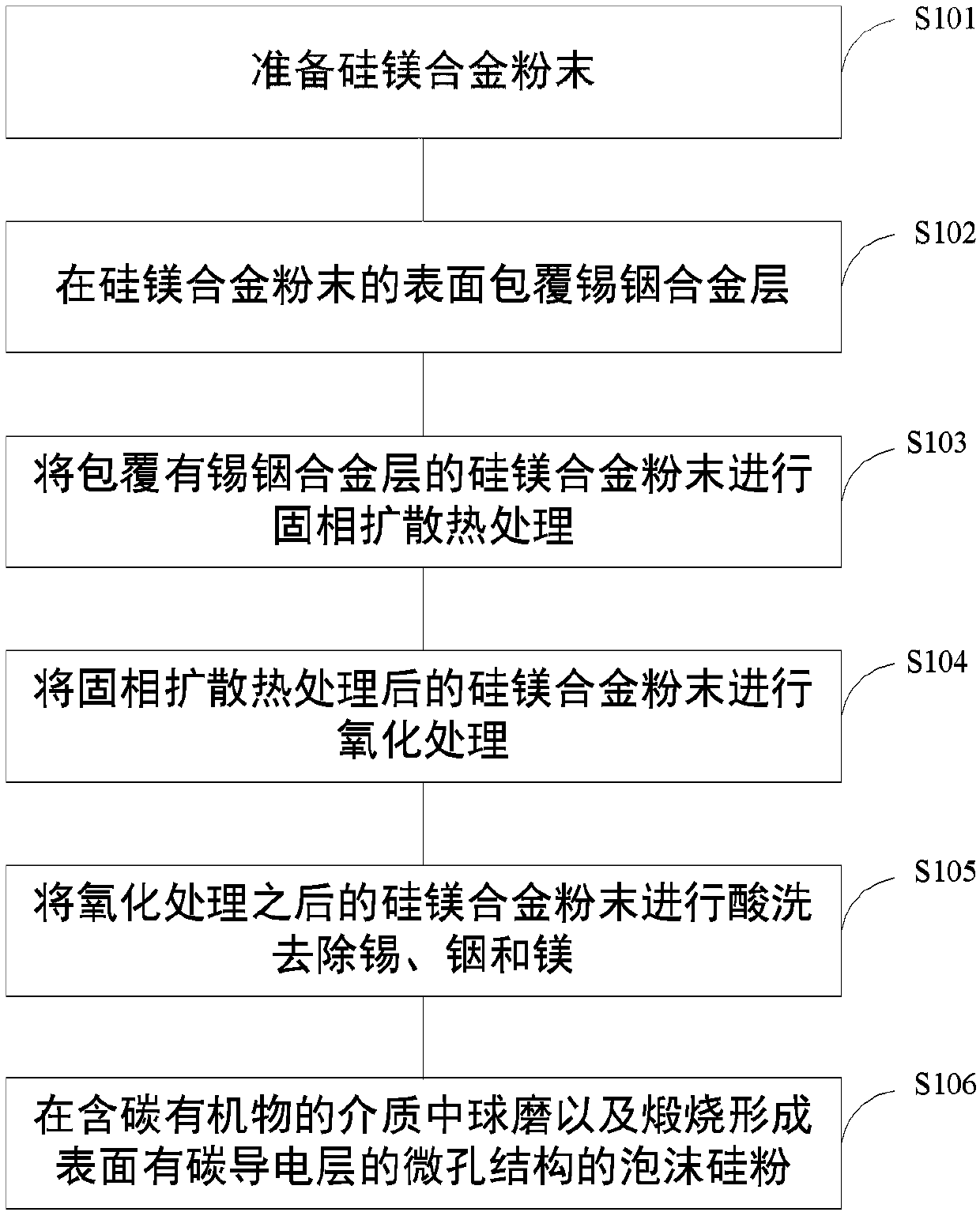

Method for preparing foam-shaped silicon powder by using silicon magnesium particles coated with tin indium alloy and silicon powder

A tin-indium alloy and foam-like technology, which is applied in the field of preparation of foam silicon powder, can solve the problems of difficulty in controlling the particle size of nano-silicon powder, low powder preparation efficiency, and difficult process control, etc., to eliminate the problem of powder overburning and crystallization The effect of reducing the risk of surface oxidation and ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The preparation method of the embodiment of the present invention is not limited to the smelting, mixing and ball milling, heat treatment, and pickling methods described above, and can also be completed by methods known to those skilled in the art, and the ball milling medium in the powder crushing process is not limited to asphalt Acetone solution, asphalt tetrahydrofuran solution, polyvinyl alcohol aqueous solution and PI / NMP solution, organic polymer compounds known to those skilled in the art can also be added to obtain a certain carbon conductive layer on the surface of silicon powder.

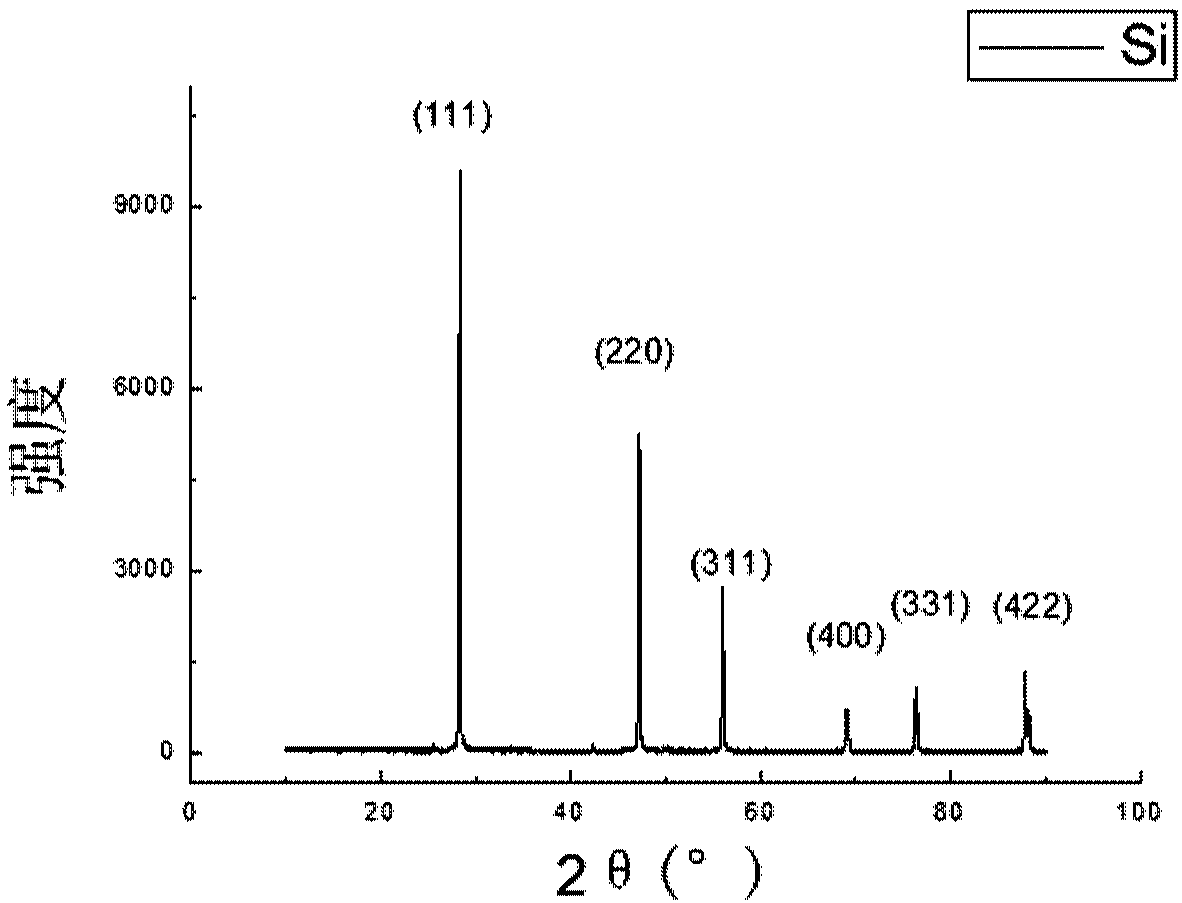

[0068] According to another aspect of the embodiments of the present invention, there is also provided a foamed silicon powder, which includes silicon powder particles, the silicon powder particles have a plurality of microporous structures, and the size of the micropores is 3 nm to 500 nm. The primary particle size is less than 200nm. The smaller the particle size of the primary p...

Embodiment 1

[0074] (1) Choose a small intermediate frequency vacuum smelting furnace, according to the capacity of the smelting graphite crucible, prepare silicon blocks and magnesium blocks at a ratio of 1 kg per furnace, containing 30-35% silicon (mass percentage), and put the ingredients in the argon atmosphere. Silicon and a small amount of massive magnesium are melted. While controlling the temperature of the melt at 1100-1200°C during the smelting process, the remaining metal magnesium blocks are added step by step. After the final heat preservation for 2-5 minutes, pour into the furnace at 250-300°C Preheated cast iron molds to obtain silicon-magnesium alloy ingots;

[0075] (2) Take out the cooled silicon-magnesium alloy ingot, coarsely crush it with a jaw crusher until the particle size is less than 5mm in a dry air atmosphere, vibrate and ball mill it under the protection of a nitrogen atmosphere, and then sieve and classify;

[0076] (3) Select silicon-magnesium alloy powder wi...

Embodiment 2

[0086] (1)(2) is identical with embodiment one;

[0087] (3) The preferred particle size is 200 grams of silicon-magnesium alloy powder of 100-200 mesh, equipped with 1000 grams of coated metal powder in a ratio of 1:5, and the coated metal powder is preferably made of a tin-indium alloy with a particle size of less than 100 mesh containing 25% tin powder, put the above-mentioned silicon-magnesium alloy powder and coated metal powder into a stainless steel tank with a diameter of 185mm, and mix in cemented carbide balls 2-4 times the weight of the above-mentioned mixed powder. The diameter of the cemented carbide ball is 6.12mm. And fill it with nitrogen or argon to protect the seal, and use a common rolling ball mill to mix and mill for 32 hours;

[0088] (4) same as embodiment one;

[0089] (5) same as embodiment one;

[0090] (6) The obtained powder after the diffusion heat treatment is packed into a tubular vacuum furnace, and the oxygen content is 5-20% (volume ratio), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com