Diamond-magnesium composite heat-radiation material as well as preparation method and application thereof

A composite heat dissipation material and diamond technology, applied in the field of diamond-magnesium composite heat dissipation materials and their preparation, can solve the problems of large interface thermal resistance, heat dissipation materials that cannot meet heat dissipation requirements, and difficult infiltration, etc., and achieve excellent thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a diamond-magnesium composite heat dissipation material, the preparation process is as follows:

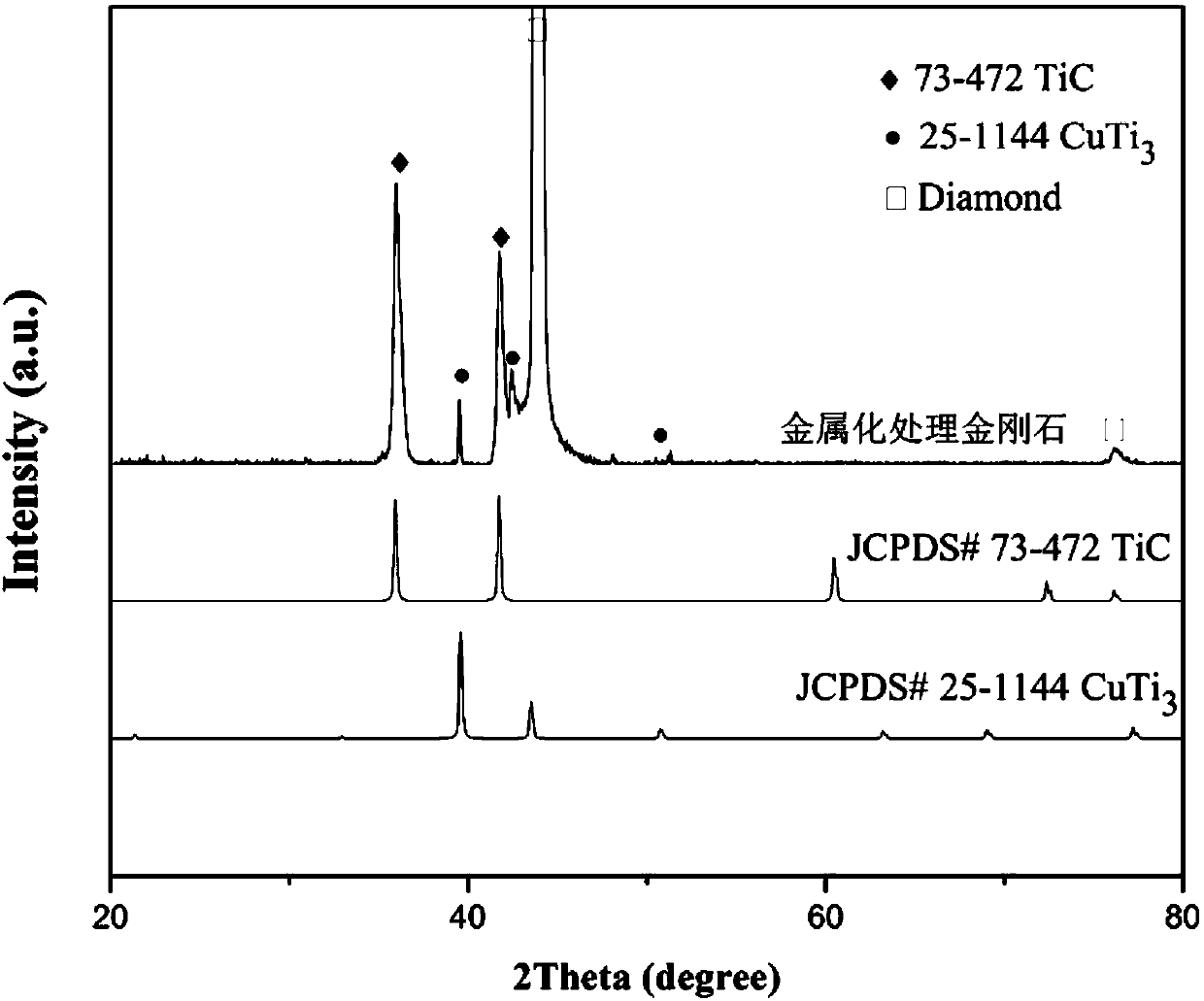

[0037] The preparation of diamond particles modified by the surface gradient layer, the specific process is: pretreatment of diamond raw materials, diamond surface pretreatment process: ultrasonic cleaning of acetone solution for 20 minutes---absolute ethanol ultrasonic cleaning for 20 minutes---deionized water washing to neutral Properties---wash with dilute nitric acid solution for 15 minutes---wash with deionized water until neutral---dry fully. After roughening and cleaning by pickling, clean diamonds are obtained; and mixed molten salt is prepared, specifically, sodium chloride and potassium chloride are mixed evenly according to the mass ratio of 2:1 to obtain mixed molten salt; according to the mass The ratio is 1:12:0.6:0.2. Weigh diamond, mixed molten salt, metal copper powder with a particle size of 1000 nm and titanium powder with a particle s...

Embodiment 2

[0042] In this embodiment, a diamond-magnesium composite heat dissipation material, the preparation process is as follows:

[0043] The preparation of diamond particles modified by the surface gradient layer, the specific process is: pretreatment of diamond raw materials, roughening and cleaning by pickling, to obtain clean diamonds; and preparation of mixed molten salt, specifically sodium chloride and chloride Potassium is mixed evenly according to the mass ratio of 2:1 to obtain mixed molten salt; according to the mass ratio of 1:10:0.08:0.5, respectively weigh diamond, mixed molten salt, and metal copper powder with a particle size of 30 nanometers and titanium powder with a particle size of 80 nanometers. After mixing these four substances evenly, they were kept in a tube furnace at 900°C under a nitrogen atmosphere for 80 minutes. After cooling to room temperature with the furnace, they were taken out and cleaned and dried to obtain a surface gradient layer modification. ...

Embodiment 3

[0047] In this embodiment, a diamond-magnesium composite heat dissipation material, the preparation process is as follows:

[0048] The preparation of diamond particles modified by the surface gradient layer, the specific process is: pretreatment of diamond raw materials, roughening and cleaning by pickling, to obtain clean diamonds; and preparation of mixed molten salt, specifically sodium chloride and chloride Potassium is mixed evenly according to the ratio of mass ratio of 2:1 to obtain mixed molten salt; according to the ratio of mass ratio of 1:15:0.15:0.1, respectively weigh diamond, mixed molten salt, and metal copper powder with a particle size of 30 nanometers and titanium powder with a particle size of 30 nanometers. After mixing these four substances evenly, heat them in a tube furnace at 920°C under a nitrogen atmosphere for 45 minutes, and take them out after cooling to room temperature with the furnace. After cleaning and drying, a surface gradient layer modifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com