Dendritic polymer-modified magnetic microspheres with uniform particle sizes and preparation method and application thereof

A technology of magnetic microspheres and polymers, applied in the field of functional materials, can solve the problems of uneven particle size, time-consuming, and many steps, and achieve good dispersion and stability, great application prospects, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

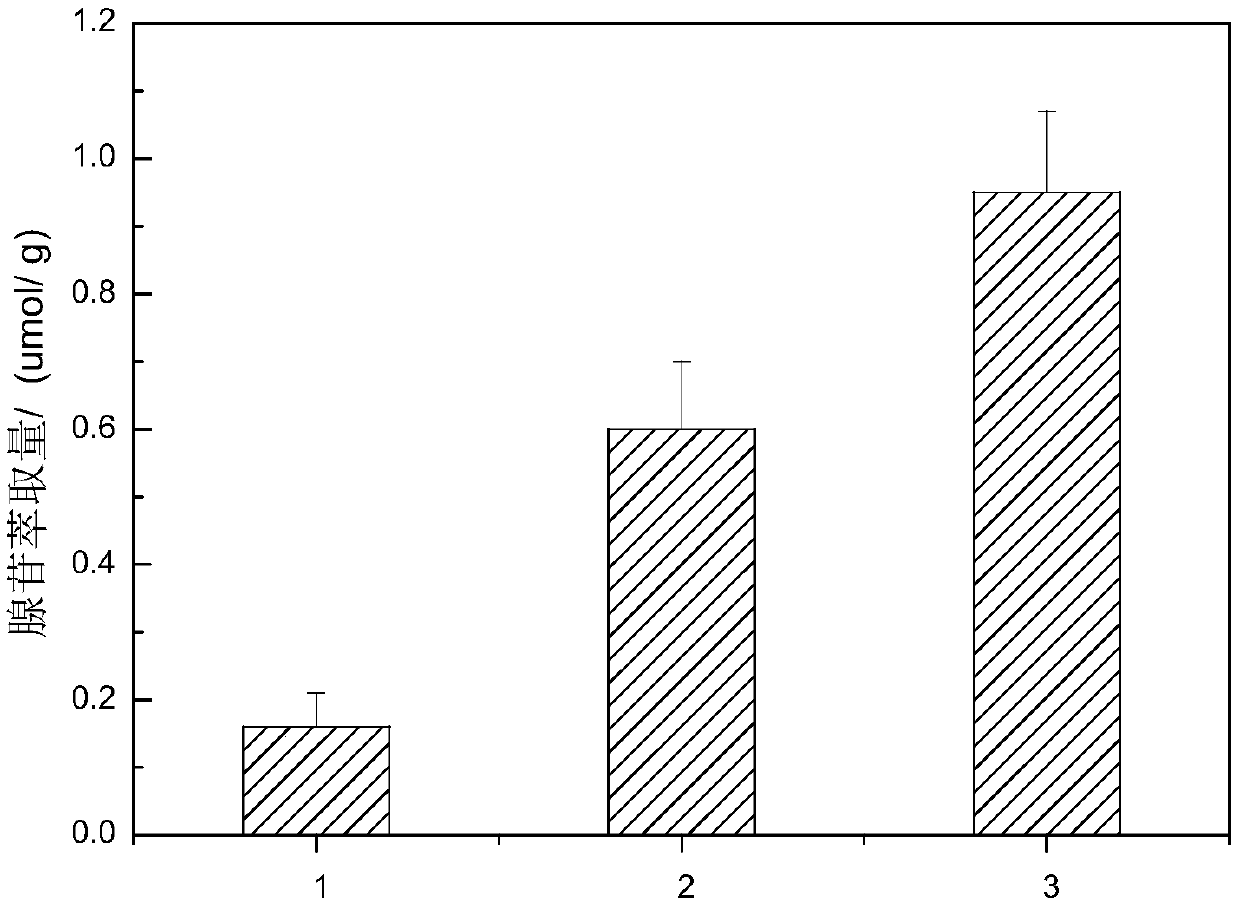

[0035] The present invention also provides a preparation method of dendritic polymer modified magnetic microspheres with uniform particle size, the method comprising the following steps: S100, preparing a solution for synthesizing magnetic microspheres; S200, uniformly dispersing the dendritic polymer In the solution for synthesizing magnetic microspheres; S300, synthesizing the mixed solution obtained in step S200 into dendrimer-modified magnetic microspheres by a one-pot hydrothermal synthesis method. Such as figure 1 The transmission electron micrograph of the magnetic ferric oxide microspheres modified by the fourth generation of PAMAM dendrimers; as image 3 The fourth generation of PAMAM dendrimer modified magnetic iron ferric oxide microspheres modified boric acid to the extraction amount of adenosine ( image 3 Middle 3), and background literature Chem.Eur.J.2006,12,6341. The extraction amount of adenosine ( image 3 Middle 1), background literature CN103157447B post...

Embodiment 1

[0043] Embodiment 1: Obtained ferroferric oxide magnetic microspheres according to the following preparation method:

[0044] 1.0 parts by weight of ferric chloride hexahydrate, 2.0 parts by weight of anhydrous sodium acetate, and 1 part by weight of the fourth-generation PAMAM dendrimers are successively dissolved in 35.0 parts by weight of ethylene glycol solution, mixed uniformly, and transferred to hydrothermal Reactor, the hydrothermal reaction temperature is 200°C. The reaction time was 6 hours. The prepared magnetic microspheres are washed 3-5 times with methanol, 3-5 times with ethanol, 3-5 times with water and 3-5 times with ethanol. Vacuum dry at 50°C for 12 hours for later use.

[0045] Such as figure 1 as shown, figure 1 It is a transmission electron micrograph of the fourth-generation PAMAM dendrimer-modified magnetic ferric oxide microspheres. It can be seen from the figure that its particle size is uniform, about 100nm.

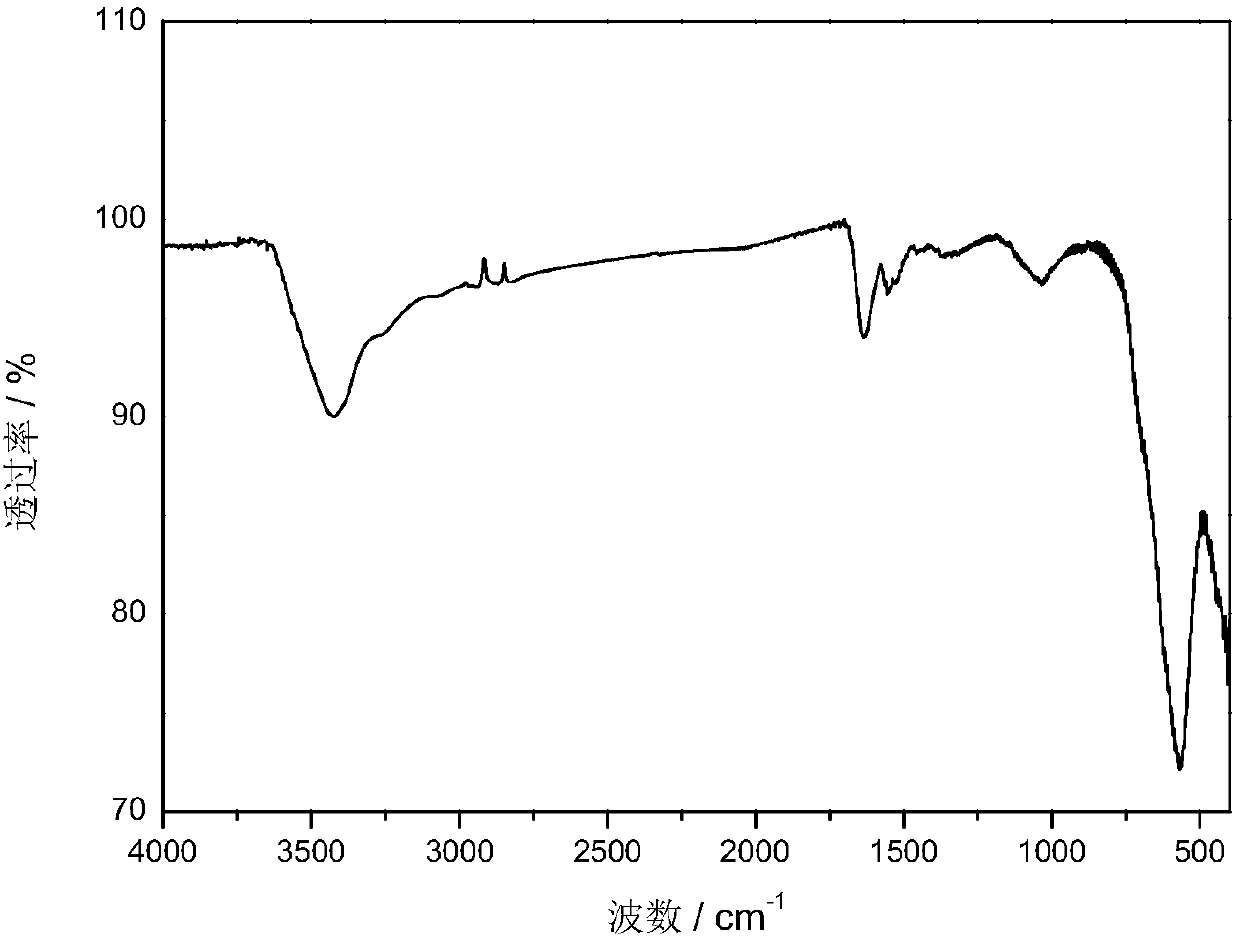

[0046] figure 2 Infrared image of m...

Embodiment 2

[0047] Embodiment 2: Preparation of cobalt oxide magnetic microspheres:

[0048] 2.0 parts by weight of cobalt chloride hexahydrate, 10 parts by weight of anhydrous sodium acetate, and 2 parts by weight of dendrimers are successively dissolved in 45 parts by weight of ethylene glycol solution, mixed uniformly, transferred to a hydrothermal reaction kettle, and hydrothermally The reaction temperature is 300°C. The reaction time was 8 hours. The prepared magnetic microspheres are washed 3-5 times with methanol, 3-5 times with ethanol, 3-5 times with water and 3-5 times with ethanol. Vacuum dry at 50°C for 12 hours for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com