Negative electrode material preparation method, negative electrode material, negative electrode piece and lithium ion battery

A negative electrode material, ionic liquid technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of blocking lithium ion transmission, large specific surface area of materials, and impact on battery life, so as to improve the charging rate and service life, avoid The effect of huge specific surface area, easy production and commercial use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the negative electrode material provided by the application is described in detail below, and the specific steps of the method include:

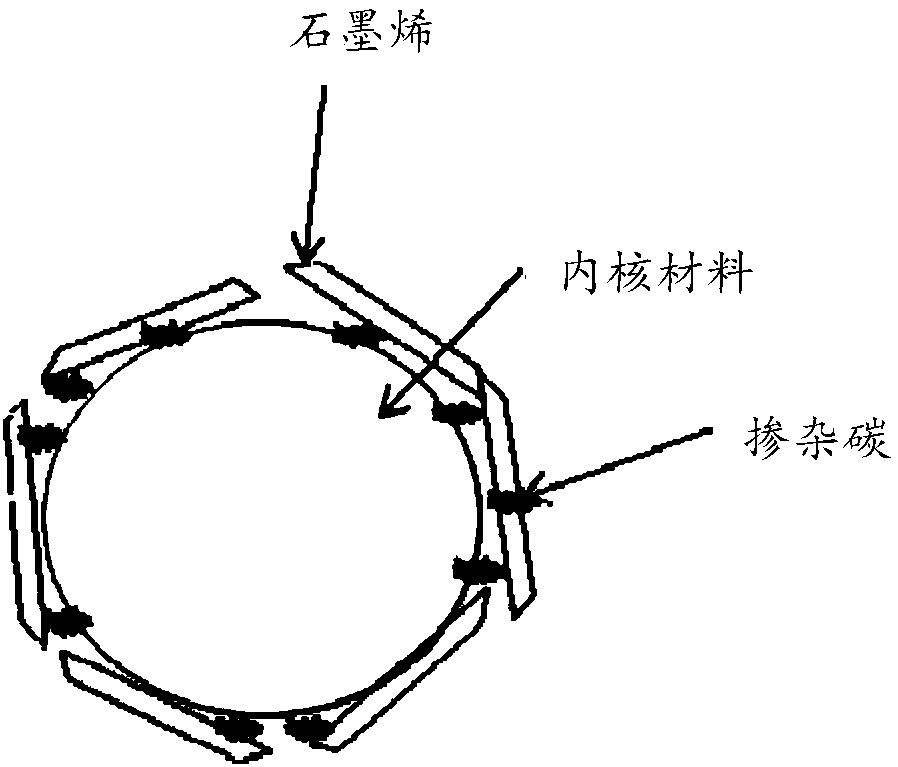

[0052] Step 110 , mixing and heating the inner core material with the heteroelement-containing polymer or the heteroelement-containing ionic liquid, so that the heteroelement-containing polymer or the heteroelement-containing ionic liquid coats the inner core material.

[0053] Specifically, in step 110, the core material is mixed with a heteroelement-containing polymer or a heteroelement-containing ionic liquid and heated. For example, a protective gas can be passed into the coating kettle, and the protective gas can be nitrogen. Or other inert gas, and carry out coating treatment at 100-250°C, so that the polymer containing heteroelement or ionic liquid containing heteroelement coats the core material, that is, the polymer coated with heteroelement is obtained or core materials for ionic liquids containing ...

Embodiment 1

[0170] Embodiment 1. Taking graphite as the core material, functionalized graphene is selected from aminated graphene, and the polymer containing heteroelements is selected from polypyrrole as an example for illustration. The specific steps are as follows:

[0171] Step 201, preparation of aminated graphene: at room temperature, take a mixture of 360ml of sulfuric acid and 40ml of phosphoric acid, slowly add 10g of natural graphite to the mixture, then add 18g of potassium permanganate into the mixture, and control the addition speed , so that the reaction temperature is controlled between 35 and 40°C. After the addition is complete, stir for 12 hours when the system is warming up to 50°C. After the reaction system is cooled to room temperature, introduce 30w% hydrogen peroxide dissolved in 3ml into the reaction solution 400ml of ice water solution, the mixed solution was filtered, the filter residue was washed with 30w% hydrochloric acid, and diluted with distilled water to pH...

Embodiment 2

[0175] Embodiment 2. Taking graphite as the core material, functionalized graphene is selected from aminated graphene, and the ionic liquid containing heteroelements is selected from triphenyl borate as an example for illustration. The specific steps are as follows:

[0176] Step 301, preparation of a negative electrode material doped with carbon-fixed graphene and coated graphite: in a dry atmosphere, 500 g of triphenyl borate and 2 kg of expanded graphite are placed in a coated kettle, under the protection of an inert gas, at a temperature of Stir at 200°C for 3 hours, after uniform mixing, add aminated graphene at a mass ratio of graphite:aminated graphene of 100:10, maintain the temperature of the coating kettle at 200°C, stir for 3 hours, and cool out of the kettle . Obtain triphenyl borate immobilized aminated graphene-coated graphite, place the obtained triphenyl borate immobilized aminated graphene-coated graphite in an atmosphere sintering furnace, feed nitrogen, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com