Hydrotalcite tablet and preparation method thereof

A technology of magnesium carbonate tablets and aluminum magnesium carbonate, which is applied in the directions of aluminum/calcium/magnesium active ingredients, pharmaceutical formulations, medical preparations with non-active ingredients, etc. problem, to achieve the effect of improving disintegration speed, low production cost, and satisfying antacid power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

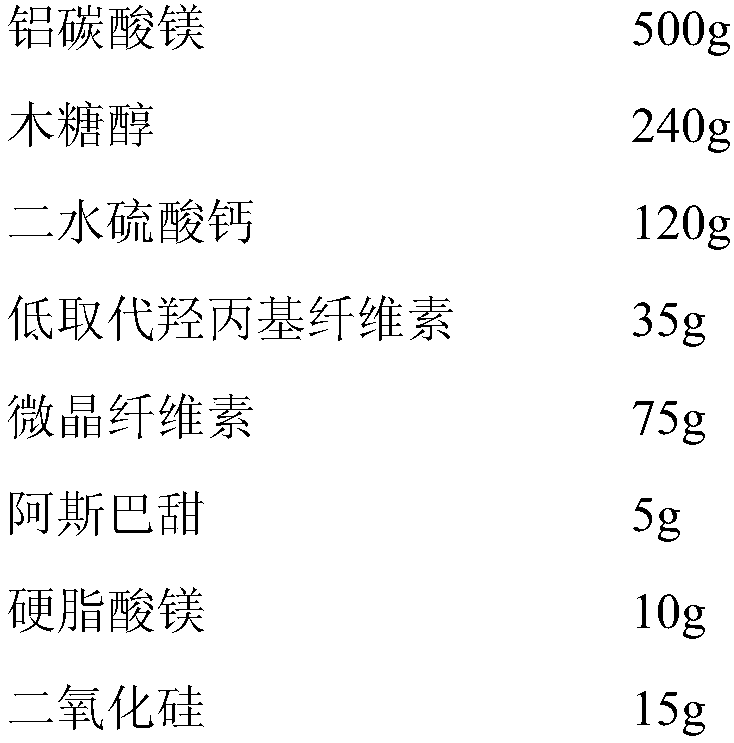

[0022] Dosage per 1000 tablets:

[0023]

[0024] Preparation:

[0025] (1) Control the particle size of aluminum magnesium carbonate, xylitol, calcium sulfate dihydrate, low-substituted hydroxypropyl cellulose, microcrystalline cellulose, aspartame, magnesium stearate and silicon dioxide to 120 μm;

[0026] (2) Aluminum magnesium carbonate, xylitol, calcium sulfate dihydrate, low-substituted hydroxypropyl cellulose, microcrystalline cellulose, aspartame, magnesium stearate and silicon dioxide are added to Mixed in the mixer for 30 minutes to obtain the total mixture;

[0027] (3) The total mixture is directly compressed into tablets, each tablet weighs 1 g, and the compression force is 35 kN.

Embodiment 2

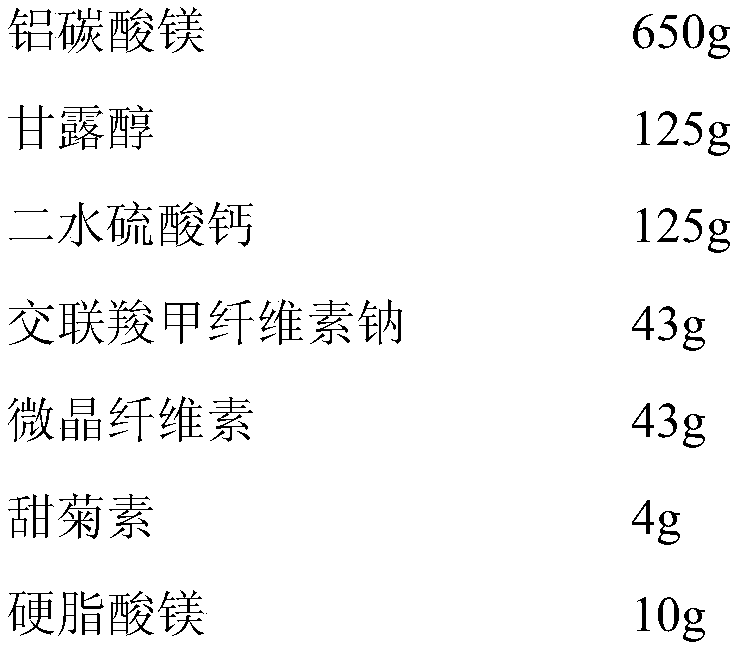

[0029] Dosage per 1000 tablets:

[0030]

[0031] Preparation:

[0032] (1) the particle size of aluminum magnesium carbonate, mannitol, calcium sulfate dihydrate, croscarmellose sodium, microcrystalline cellulose, stevia and magnesium stearate is controlled at 150 μm;

[0033] (2) Aluminum magnesium carbonate, mannitol, calcium sulfate dihydrate, croscarmellose sodium, microcrystalline cellulose, stevioside and magnesium stearate are taken by weighing recipe quantity, add in mixer and mix for 15 minutes to obtain total mixture;

[0034] (3) The total mixture is directly compressed into tablets, each tablet weighs 1 g, and the compression force is 30 kN.

Embodiment 3

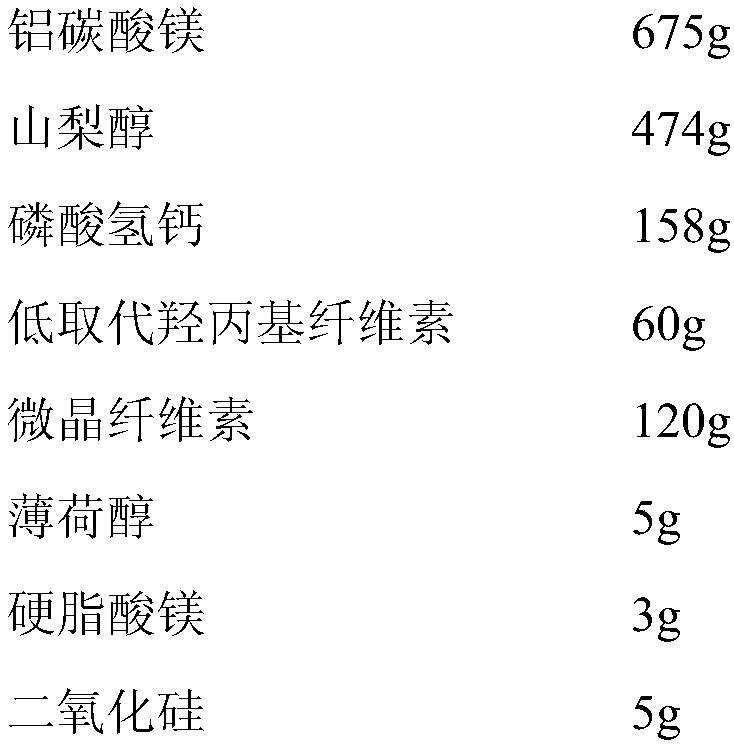

[0036] Dosage per 1000 tablets:

[0037]

[0038] Preparation:

[0039] (1) Control the particle size of aluminum magnesium carbonate, sorbitol, calcium hydrogen phosphate, low-substituted hydroxypropyl cellulose, microcrystalline cellulose, menthol, magnesium stearate and silicon dioxide at 160 μm;

[0040] (2) Weigh aluminum magnesium carbonate, sorbitol, calcium hydrogen phosphate, low-substituted hydroxypropyl cellulose, microcrystalline cellulose, menthol, magnesium stearate and silicon dioxide, add to the mixer and mix 45 minutes to get the total mixture;

[0041] (3) The total mixture is directly compressed into tablets, each tablet weighs 1.5 g, and the compression force is 45 kN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com