Green and environment-friendly nano film and application thereof in metal corrosion resistance field

A nano-film, green and environmentally friendly technology, applied in the direction of electrolytic organic material coating, etc., can solve the problem of not being able to completely isolate the penetration of water molecules, and achieve the effect of simple and practical preparation process, environmental friendliness, and not easy to be oxidized and decomposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: preparation of green environment-friendly nano film

[0035] Material preparation: pure copper (Shanghai Hongxin Metal Material Co., Ltd., purity greater than 99.95%), copper sheet with a size of 50mm×20mm×0.3mm, and the copper sheet is sprayed with 2.5μm, 1.5μm and 0.5μm diamond polishing agents in turn Polish and polish to a mirror-like surface, then immerse in acetone and ultrasonically clean for 15 minutes to degrease and remove other organic pollutants, then rinse with deionized water and absolute ethanol in sequence, and then blow dry with nitrogen.

[0036] 6-N,N-Dibutylamine-1,3,5-triazine-2,4-thiol monosalt (DBN)

[0037] Specific preparation process:

[0038] (1) Electrodeposition coating: the test temperature is room temperature, and the composition of the plating solution: 6-N,N-dibutylamine-1,3,5-triazine-2,4-thiol monosalt (DBN) and carbonic acid Sodium is used as a mixed solution of supporting electrolyte, and the concentration of DBN in t...

Embodiment 2

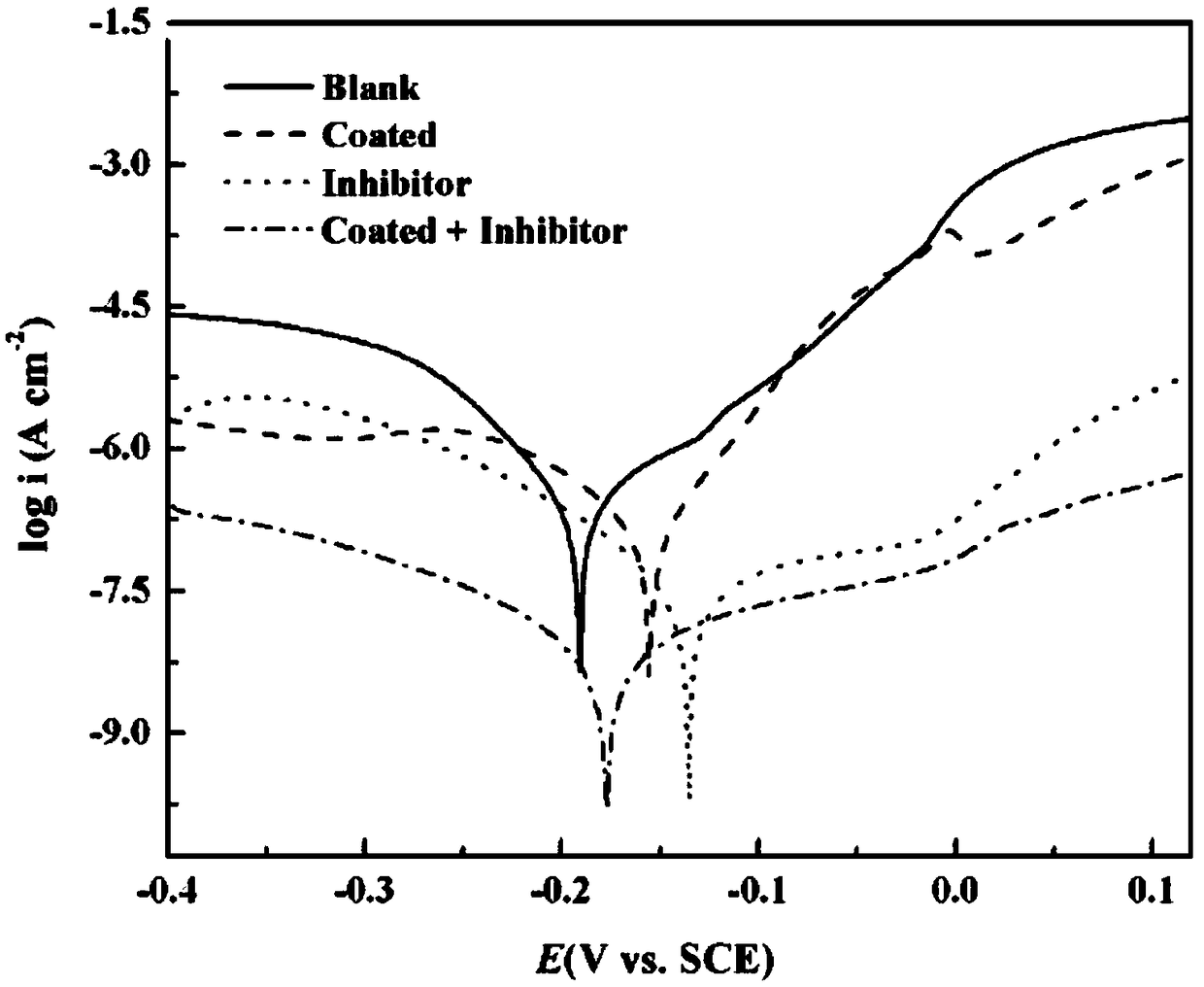

[0042] The sample prepared by embodiment 1 is immersed in the corrosive medium to detect its related properties, wherein the measurement of electrochemical parameters is carried out on the Wuhan Koster CS310 type electrochemical workstation, and the experiment adopts a standard three-electrode electrolytic cell, including a working electrode (copper electrode ), counter electrode (graphite electrode, size 50mm×30mm×3mm) and reference electrode (saturated calomel electrode SCE). Wherein, the reference electrode is connected to the electrolytic cell with a Lukin capillary salt bridge, all measured potentials are relative to the potential of the saturated calomel electrode (SCE), and the corrosion medium is 3.5wt% NaCl solution (simulated seawater).

[0043] Before the test, wrap the sample with polyimide tape so that the exposed area is 1cm 2 For the working electrode, first put the working electrode in the corrosive medium and soak it for about 0.5h, and then measure the change...

Embodiment 3

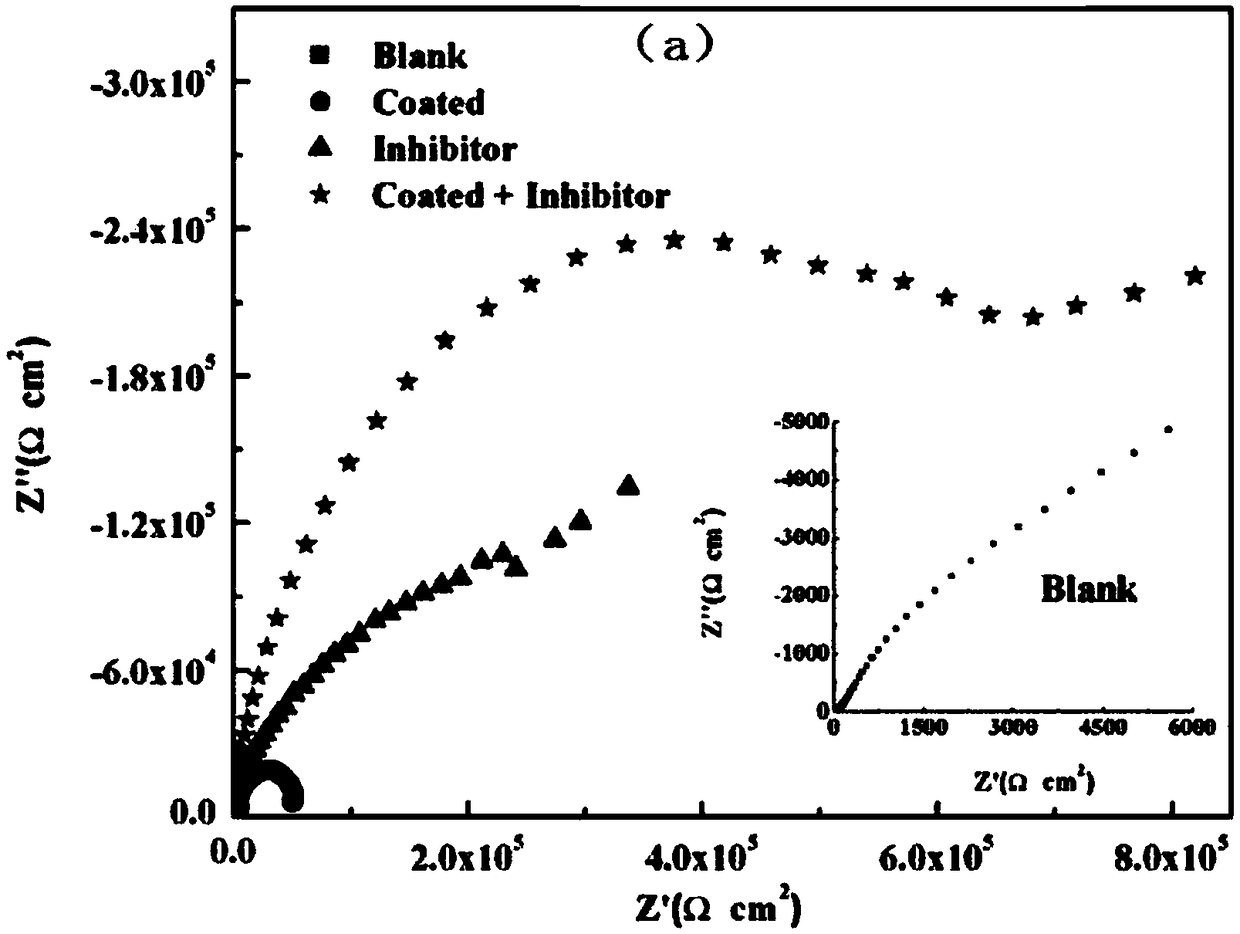

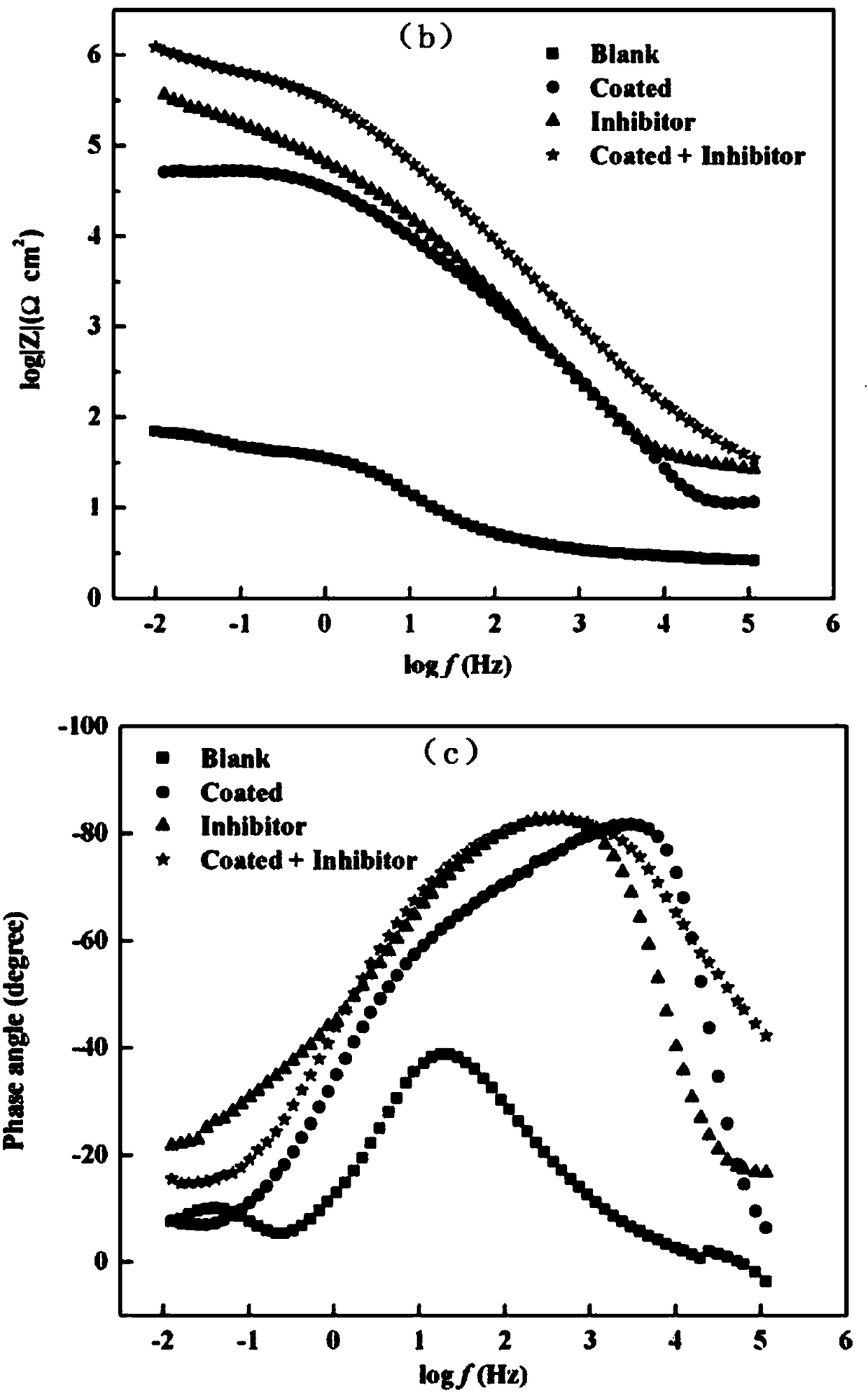

[0055] On the basis of Example 2, in order to further explore the anti-corrosion effect of electrodeposited film combined with adsorption on copper, the electrochemical impedance spectra of copper samples modified by different methods in 3.5% NaCl solution were measured, and the results are as follows figure 2 Shown in the figure are the electrochemical impedance Nyquist spectra of blank copper (without any treatment), electrodeposition coating, DBN adsorption and electrodeposition coating combined with DBN adsorption treatment of pure copper samples in sodium chloride solution, impedance Bode and phase angle diagrams, Z' and Z" in the figure are the real part and imaginary part of the copper electrode surface impedance value, and |Z| is the total impedance of the copper electrode.

[0056] from figure 2 It can be seen in a that all the curves present an irregular compressed semicircular capacitive reactance arc at the high frequency end. The compression deformation of the h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap