A kind of nano tin/carbon composite material and preparation method thereof

A carbon composite material, nano-tin technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as the inability to guarantee effective suppression, the inability to guarantee the uniform distribution of tin, and the inability to guarantee the distribution of tin. , to achieve the effects of low cost, simple operation, and inhibition of hydrogen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

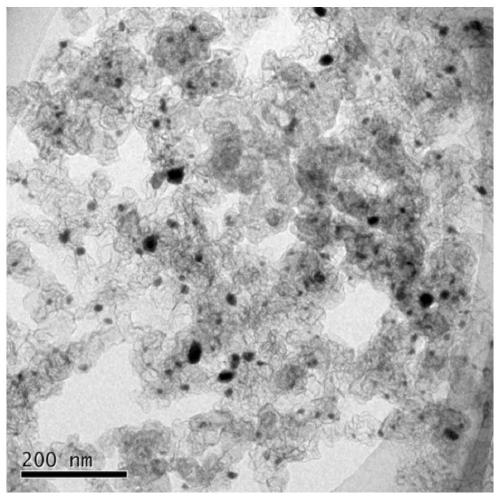

Image

Examples

Embodiment 1

[0046] step one

[0047] Add 100 ml of deionized water to a 250 ml beaker, then dissolve 1.2 g of sodium hydroxide, add 4.8 g of EDTA-Na and stir to dissolve, then add 2.32 g of tin nitrate, and ultrasonically obtain a clear solution for 30 minutes.

[0048] step two

[0049] Add 3g of conductive carbon black, then stir for 2 hours to disperse the carbon powder evenly, and finally remove the aqueous solution by suction filtration, step 3

[0050] The obtained solid was vacuum-dried at 60° C. for 12 hours, and then calcined in an argon atmosphere at 280° C. for 30 minutes.

[0051] step four

[0052] The resulting sample was redispersed in water at 30°C, and 50ml of 3g L -1 aqueous sodium borohydride solution. After the dropwise addition, react for 3 minutes, and quickly filter the reaction solution with deionized water and ethanol, and then repeatedly wash with deionized water and ethanol to obtain product A-nano-tin / carbon composite material (3.6 g). In product A, the pa...

Embodiment 2

[0057] Add 40 ml of propylene glycol to a 100 ml beaker, add 0.8 g of tin chloride, and obtain a clear solution by ultrasonication for 30 minutes, then add 1 g of carbon fiber, and then stir for 1.5 hours to disperse the carbon powder evenly. After drying under vacuum for 10 hours, it was calcined at 350° C. for 40 minutes in a nitrogen atmosphere. The resulting sample was redispersed in water at 30°C, and 40ml of 1.5g L -1 Sodium borohydride solution in isopropanol. After the dropwise addition, react for 2 minutes, and quickly filter the reaction solution with deionized water and ethanol to wash repeatedly to obtain the final product. In the final product, the particle size of the tin is 5-15nm.

[0058] Get this product 0.1g, common conductive carbon and tin are mixed and weighed 0.1g according to the ratio of this product, and the tin-carbon composite material (comparative example 1) 0.1g of equal proportion prepared by conventional direct liquid phase method; Add 0.8g re...

Embodiment 3

[0060] Add 120ml of deionized water to a 250ml beaker, add 3.8g of sodium alginate, stir to dissolve, add 2.1g of tin nitrate, and ultrasonically obtain a clear solution for 40 minutes, then add 2.4g of carbon nanotubes, and then stir for 2.5 hours to become carbon powder Disperse evenly, and finally remove the aqueous solution by suction filtration, vacuum-dry the obtained solid at 60°C for 14 hours, and then calcinate at 330°C for 30 minutes in an argon atmosphere. The resulting sample was redispersed in water at 30°C, and 30ml of 2g L -1 aqueous sodium borohydride solution. After the dropwise addition, react for 2 minutes, and quickly filter the reaction solution with deionized water and ethanol to wash repeatedly to obtain the final product. In the final product, the particle size of the tin is 8-20nm.

[0061] Get this product 0.1g, common conductive carbon and tin are mixed and weighed 0.1g according to the ratio of this product, and the tin-carbon composite material (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com