Placenta oligopeptide probiotic composite preparation and preparation method thereof

A compound preparation and probiotic technology, applied in the directions of bacteria, lactobacillus, bifidobacteria, etc. used in food preparation, can solve the problems such as the use, sales and reporting of compound preparations of animal placenta extract and probiotics that have not been found yet, Achieve the effect of enhancing immunity, good thermal stability and low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A compound preparation of animal placenta oligopeptides and probiotics, the specific preparation method of which is as follows:

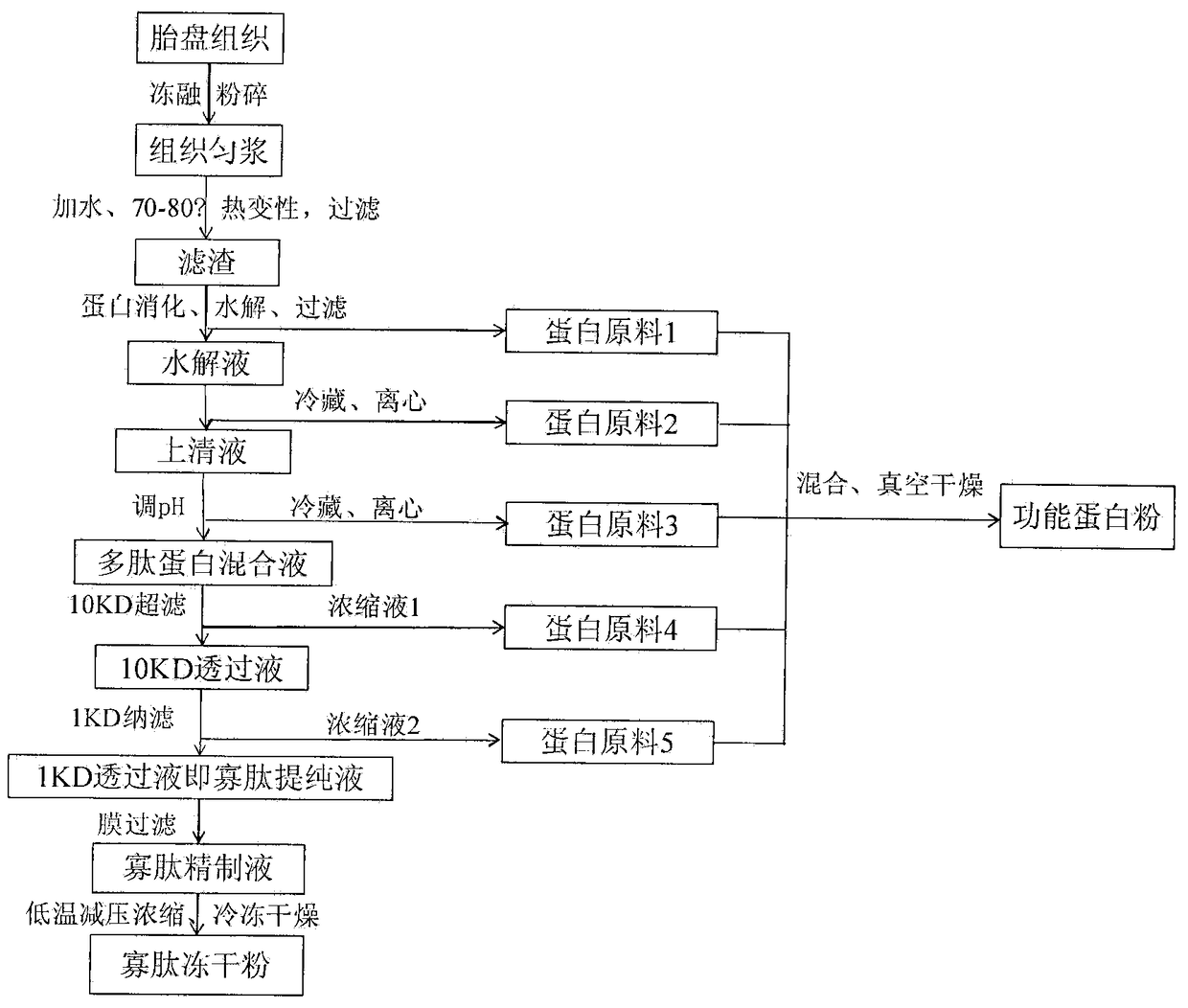

[0039] 1. Extraction process of animal placenta oligopeptides

[0040] (1) Raw material processing: collect the fresh animal placenta and its appendages that have passed the quarantine, and freeze them immediately for 26 hours. Take out the frozen placenta raw material, and when it is thawed to a semi-frozen state, use a meat grinder, a high-speed tissue masher, and a colloid grinder in turn to grind it into a homogenous slurry.

[0041] (2) Mild thermal denaturation: Weigh the raw material after homogenization, add an equal volume of tap water, heat to 70°C while stirring, keep it warm for 10 minutes, filter immediately while it is hot, discard the filtrate, and collect the filter residue.

[0042] (3) Protein hydrolysis: weigh the filter residue and put it in the reaction kettle, add fresh pancreatic pulp with 25% of the weight of the filt...

Embodiment 2

[0053] A compound preparation of animal placenta oligopeptides and probiotics, the specific preparation method of which is as follows:

[0054] 1. Extraction process of animal placenta oligopeptides

[0055] (1) Raw material processing: collect the fresh animal placenta and its appendages that have passed the quarantine, and freeze them immediately for 48 hours. Take out the frozen placenta raw material, and when it is thawed to a semi-frozen state, use a meat grinder, a high-speed tissue masher, and a colloid grinder in turn to grind it into a homogenous slurry.

[0056] (2) Mild thermal denaturation: Weigh the raw material after homogenization, add an equal volume of tap water, heat to 80°C while stirring, keep it warm for 15 minutes, filter immediately while it is hot, discard the filtrate, and collect the filter residue.

[0057] (3) Protein hydrolysis: weigh the filter residue and put it in the reaction kettle, add fresh pancreatic pulp with 30% weight of the filter resi...

Embodiment 3

[0068] A compound preparation of animal placenta oligopeptides and probiotics, the specific preparation method of which is as follows:

[0069] 1. Extraction process of animal placenta oligopeptides

[0070] (1) Raw material processing: collect the fresh animal placenta and its appendages that have passed the quarantine, and immediately freeze them for 24 hours. Take out the frozen placenta raw material, and when it is thawed to a semi-frozen state, use a meat grinder, a high-speed tissue masher, and a colloid grinder in turn to grind it into a homogenous slurry.

[0071] (2) Mild thermal denaturation: Weigh the raw materials after homogenization, add an equal volume of tap water, heat to 75°C while stirring, keep warm for 12 minutes, filter while hot, discard the filtrate, and collect the filter residue.

[0072] (3) Protein hydrolysis: weigh the filter residue and put it in the reaction kettle, add fresh pancreatic pulp with 27% of the filter residue weight, add 2.5 times t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com