Preparation method of silk fibroin material of composite nano-grade hydroxyapatite and application of silk fibroin material in repairing bone fracture parts

A technology of nano-hydroxyapatite and hydroxyapatite, which is applied in the fields of material science and clinical medicine, can solve problems such as inability to use, human discomfort, and corrosivity of bone tissue, and achieve simple methods, speed up repair, and promote proliferation and differentiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

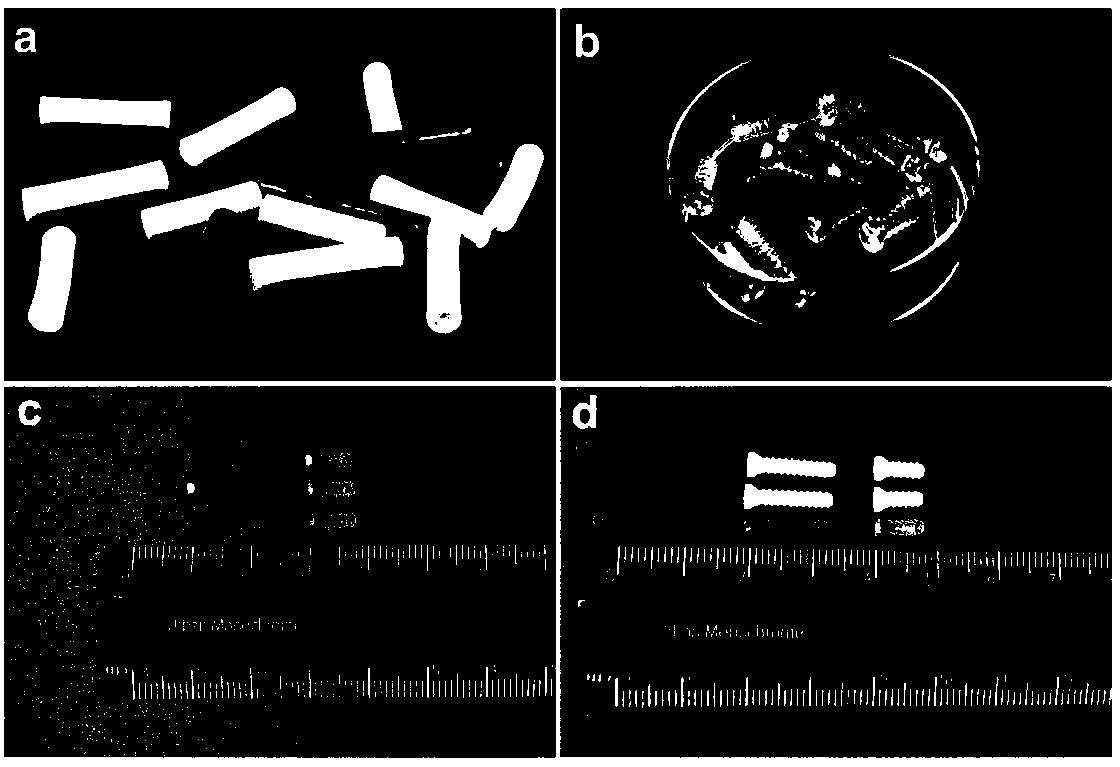

[0031] Silkworm cocoons are degummed by steaming 0.005wt% sodium carbonate aqueous solution for 0.5h, and the degummed silk is dissolved in 9.3mol / L lithium bromide solution. The silk fibroin solution dissolved in lithium bromide was dialyzed in distilled water for 3 days and then freeze-dried to obtain a white foamy silk fibroin sample. The foamy silk fibroin is crushed and mixed into nano-sized hydroxyapatite (HA), and the mixture is made into a mixture in which HA accounts for 0% to 75% by weight of the total mass of HA and SF, and the mixture is dissolved in hexafluoroisopropanol to prepare A 25 wt% solution was obtained. Pour the silk fibroin / nanometer hydroxyapatite mixed solution into a pre-designed mold (the mold is made of polymer material polypropylene and is cylindrical, so as to make a cylindrical composite material at last), Then placed in methanol solvent for self-assembly regeneration. The methanol-treated material was air-dried and machined into bone screws. ...

Embodiment 2

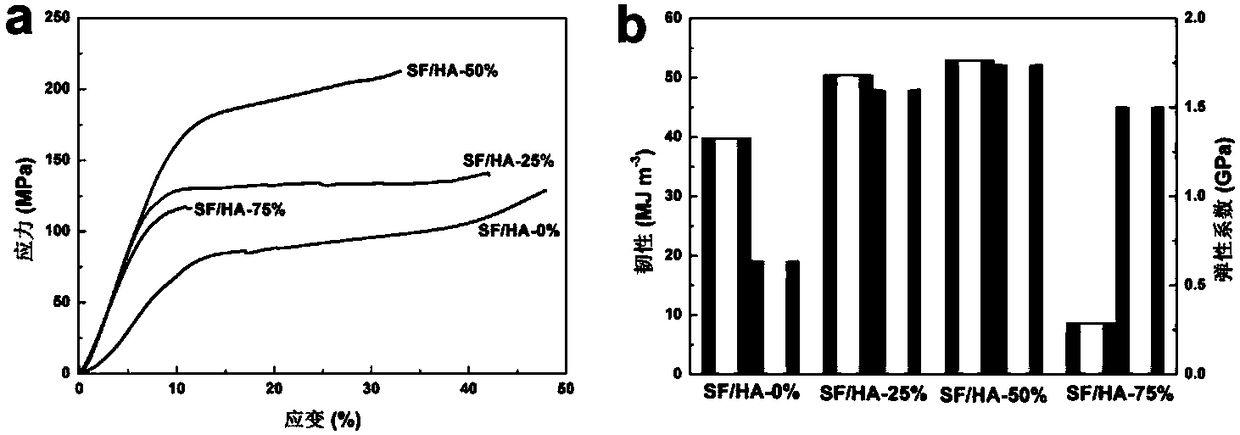

[0033] The silk fibroin / nano-hydroxyapatite composites with different HA contents were made into cylinders with a diameter of 5 mm and a height of 1 cm, and their compressive properties were characterized. figure 2 As shown, we investigate the mechanical properties of the material through compression tests. figure 2 a shows the compressive stress-strain curve of the material, and the results show that the compressive strength and strain of SF-HA0 are 128.2 MPa and 47.9%, respectively. When the nHA content was 50wt%, the compressive strength of the composite reached 212.6MPa, while the compressive strain dropped to 33%. Further increasing the nHA content, the mechanical properties of the composites decreased sharply, indicating that nHA aggregated in the SF matrix. On the other hand, the elastic modulus of the material increases from 0.64GPa (SF / HA-0%) to 1.75GPa (SF / HA-50%); the toughness increases from 39.8MJ m -3 (SF / HA-0%) increased to 52.9MJ m -3 (SF / HA-50%), indicati...

Embodiment 3

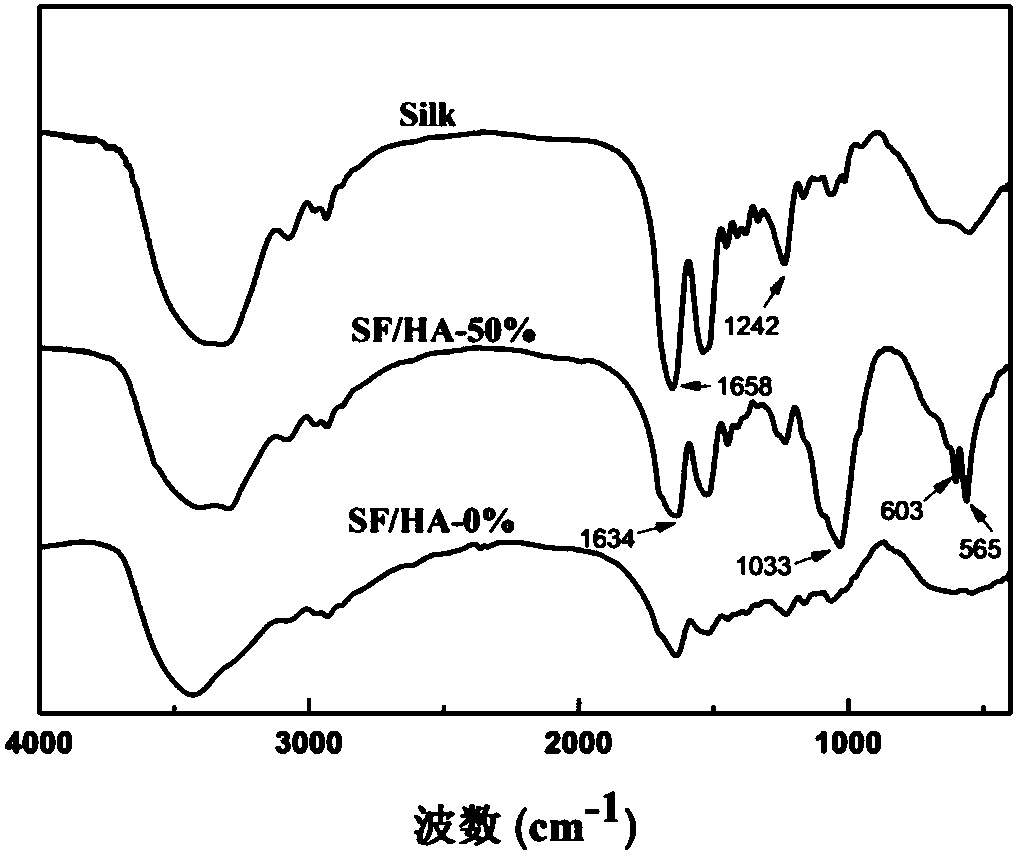

[0035] The silk fibroin / nano-hydroxyapatite composite material obtained in Example 1 was cut into powder, and it was detected by Fourier transform infrared spectroscopy to study the mechanism of performance enhancement of silk fibroin after methanol treatment. image 3 Shown at 1658cm -1 、1545cm -1 and 1242cm -1 The absorption peaks at the positions belong to the characteristic absorption peaks of amide I, amide II and amide III of the silk fibroin molecule (Silk), indicating that its secondary structure is a random coil; after methanol regeneration, the three characteristic peaks are transferred to 1634cm -1 、1520cm -1 and 1230cm -1 , indicating that the silk protein transforms from random coils to β-sheets, which is beneficial to increase the strength of the material. In addition, in the infrared spectrum of the composite material 603cm -1 and 565cm -1 The characteristic absorption of corresponds to the phosphate O-P-O bending vibration, demonstrating the presence of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com