Modified silica gel, and preparation method and adsorption application method thereof

A silica gel, modified technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, silicon compounds, etc., can solve the problems of large amount of eluent, waste residue, waste liquid and waste gas, etc., and achieve high content of surface functional groups , the effect of reducing waste, good adsorption selection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

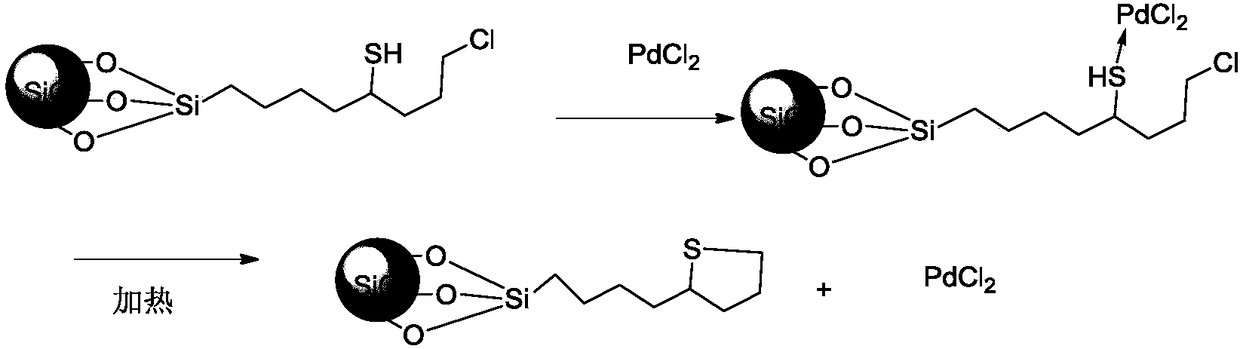

[0042] According to another aspect of the present invention, there is provided a method for preparing modified silica gel, including:

[0043] The acidified silica gel, a solvent, an alkaline reagent, a silane coupling agent containing a mercapto functional group and a halogen are mixed and heated to reflux to obtain the modified silica gel.

[0044] The steps to activate silica gel by acidification treatment include: boiling with 1:1 nitric acid (the volume ratio of concentrated nitric acid to water is 1:1) for three hours, cooling, washing with water until neutral, and then using 1:1 hydrochloric acid (concentrated hydrochloric acid) The volume ratio to water is 1:1) Shaking and soaking for 6 hours, washing with water until no chlorine ions; drying at 160 degrees for 12 hours, cooling in a desiccator to obtain the acidified silica gel.

[0045] According to an embodiment of the present invention, the heating and refluxing is performed under stirring conditions, and the stirring spe...

Embodiment approach

[0046] According to an embodiment of the present invention, the preparation method of the modified silica gel further includes:

[0047] Wash the resulting modified silica gel with toluene, ethyl acetate, ethanol, water, and ethanol successively;

[0048] Dry under reduced pressure at 50-70 degrees Celsius to obtain solid modified silica gel.

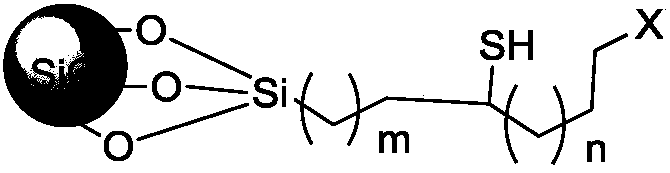

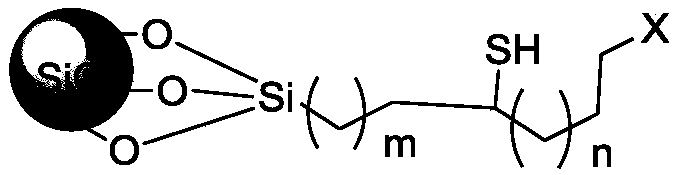

[0049] According to an embodiment of the present invention, the silane coupling agent containing mercapto functional groups and halogens is selected from 1-chloro-8-(trimethoxysilyl)octane-4-thiol, 1-bromo-8 -(Trimethoxysilyl)octane-4-thiol, 1-iodo-8-(trimethoxysilyl)octane-4-thiol, 1-chloro-9-(trimethoxysilyl) Nonane-5-thiol, 1-bromo-9-(trimethoxysilyl)nonane-5-thiol, 1-iodo-9-(trimethoxysilyl)nonane-5-thiol, 1-chloro-10-(trimethoxysilyl)decane-6-mercaptan, 1-bromo-10-(trimethoxysilyl)decane-6-mercaptan, 1-iodine-10-(trimethyl (Oxysilyl)decane-6-thiol, 1-chloro-7-(trimethoxysilyl)heptane-4-thiol, 1-bromo-7-(trimethoxysilyl)heptane- 4-merc...

preparation Embodiment 1

[0056] Add 4.0 kg of silica gel (purchased from Qingdao Bangkai, preferably 200-300 mesh silica gel powder), 12 kg of toluene, 200 g of triethylamine, and 1-chloro-8-(trimethoxysilyl)octane-4 in a 200L kettle. -Mercaptan (purchased from Qufu Jiaye New Chemical Material Co., Ltd.) 3kg;

[0057] Start stirring, stirring speed 200r / min; keep refluxing reaction for 24 hours, reduce to room temperature for filtration;

[0058] Wash with toluene, ethyl acetate, ethanol, water, ethanol in sequence, and dry under reduced pressure at 60 degrees Celsius to obtain 4.06 kg of modified silica gel.

[0059] Elemental analysis was performed on the modified silica gel obtained in Preparation Example 1, and the results were: C (5.13%), H (0.86%), S (1.71%), Cl (1.89%). It was confirmed that after the reaction, the chlorooctane containing the thiol group had been connected to the silica gel. And according to the elemental composition analysis, it can be calculated that the amount of substances conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com