Nitrogen, phosphorus and sulfur co-doped mesoporous carbon spheres and preparation method of mesoporous carbon spheres

A mesoporous carbon and co-doping technology, which is applied in the preparation of carbon materials, mesoporous carbon spheres and its preparation, can solve the problems of single channel distribution, poor electrical conductivity, disordered structure, etc., and achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

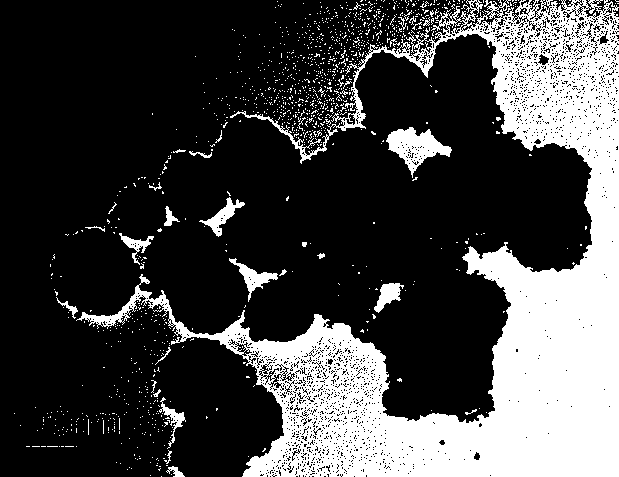

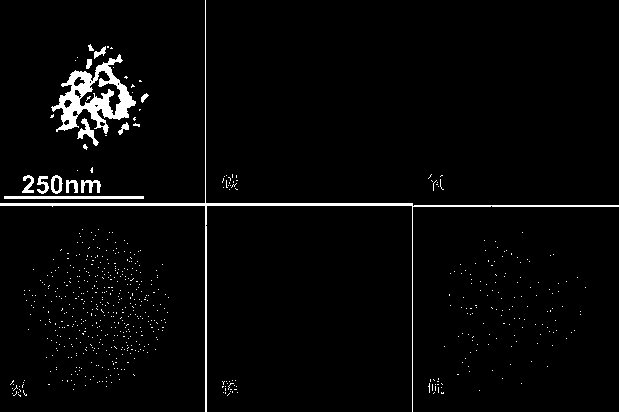

Image

Examples

Embodiment 1

[0020] Example 1: Disperse 2.55g of silica sol, 0.56g of aniline solution and 2.12g of phytic acid solution in 140mL of water, add 7mL of 1M hydrochloric acid solution, wherein the molar ratio of phytic acid to aniline is 3:10, The mass ratio of silicon to aniline is 1:1, and the volume percentage of hydrochloric acid is 5%. After stirring for a certain period of time, slowly add ammonium persulfate solution dropwise at 5°C, wherein the molar ratio of ammonium persulfate to aniline is 1:1, and let stand to react After 24 hours, the polyaniline / phytic acid / ammonium persulfate / silica polymer was obtained by drying. The polyaniline / phytic acid / ammonium persulfate / silicon dioxide polymer is placed in a tube furnace, under the protection of pure nitrogen or argon inert gas to achieve the next step of temperature-controlled high-temperature calcination, the calcination temperature is 800 ° C, and the holding time is 2 hours; The heating rate is 2°C / min, and the inert gas flow rate i...

Embodiment 2

[0021] Example 2: Disperse 5.00g of silica sol, 0.56g of aniline solution and 2.24g of phytic acid solution in 140mL of water, add 14mL of 1M hydrochloric acid solution, wherein the molar ratio of phytic acid to aniline is 3:5, The mass ratio of silicon to aniline is 2:1, and the volume percentage of hydrochloric acid is 10%. After stirring for a certain period of time, slowly add ammonium persulfate solution dropwise at 5°C, wherein the molar ratio of ammonium persulfate to aniline is 1:1, and let stand to react After 24 hours, the polyaniline / phytic acid / ammonium persulfate / silica polymer was obtained by drying. The polyaniline / phytic acid / ammonium persulfate / silicon dioxide polymer is placed in a tube furnace, under the protection of pure nitrogen or argon inert gas to achieve the next step of temperature-controlled high-temperature calcination, the calcination temperature is 800 ° C, and the holding time is 2 hours; The heating rate is 2°C / min, and the inert gas flow rate ...

Embodiment 3

[0022] Example 3: Disperse 2.52g of silica sol, 0.56g of aniline solution and 2.24g of phytic acid solution in 140mL of water, add 7mL of 3M hydrochloric acid solution, wherein the molar ratio of phytic acid to aniline is 3:10, The mass ratio of silicon to aniline is 1:1, and the volume percentage of hydrochloric acid is 5%. After stirring for a certain period of time, slowly add ammonium persulfate solution dropwise at 5°C, wherein the molar ratio of ammonium persulfate to aniline is 1:4, and let stand to react After 24 hours, the polyaniline / phytic acid / ammonium persulfate / silica polymer was obtained by drying. The polyaniline / phytic acid / ammonium persulfate / silicon dioxide polymer is placed in a tube furnace, under the protection of pure nitrogen or argon inert gas for next step of temperature-controlled high-temperature calcination, the calcination temperature is 900°C, and the holding time is 4h; The heating rate is 5°C / min, and the inert gas flow rate is 50mL / min to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com