Preparation method of MOF (metal-organic framework)-derived cobalt/carbon nanocomposite

A technology of metal-organic frameworks and composite materials, which is applied in the field of preparation of cobalt/carbon nanocomposites, can solve the problems of high reaction temperature, reaction time, unfavorable large-scale industrial production of MOF precursors, etc., and achieve easy removal and excellent selectivity Adsorption performance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a cobalt / carbon composite material derived from a metal organic framework, specifically comprising the following steps:

[0028] (1) Dissolve 0.484g 4,4′-biphenyldicarboxylic acid and 0.224g KOH in 25mL water to make a solution, dissolve 0.582g cobalt nitrate hexahydrate in 25mL water to make a solution, and then put the two solutions at room temperature Mix and stir for 0.5 hours at a stirring speed of 500r / min, then perform centrifugal washing at a rotational speed of 8000r / min, put them in an oven, and dry at 70°C for 5 hours to obtain a cobalt-based metal-organic framework precursor;

[0029] (2) Put the precursor obtained in step (1) into a quartz boat, use nitrogen as a protective gas in a tube furnace, heat up to 900°C at a heating rate of 5°C / min, keep it for 3 hours and start to cool down, After cooling to room temperature, the black cobalt / carbon nanocomposite material was obtained.

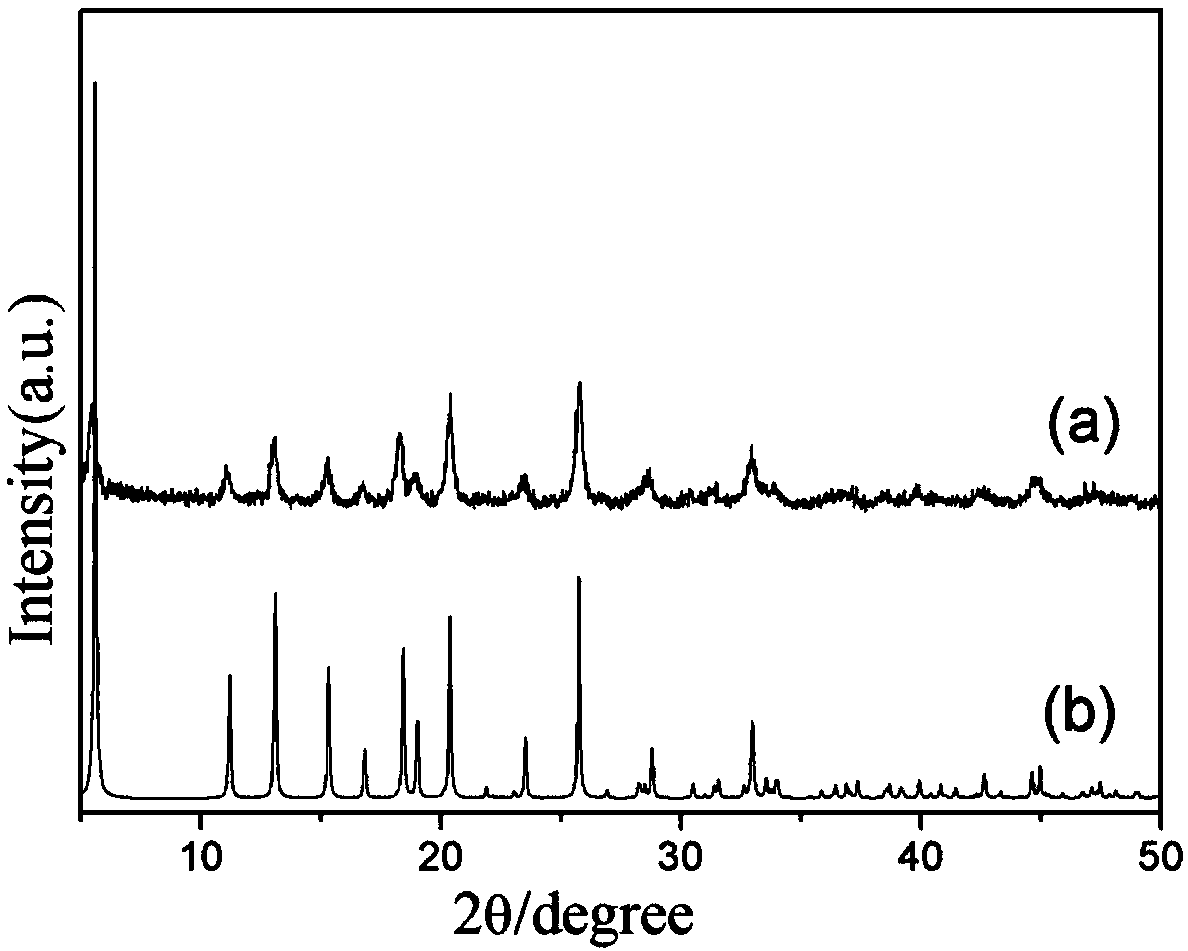

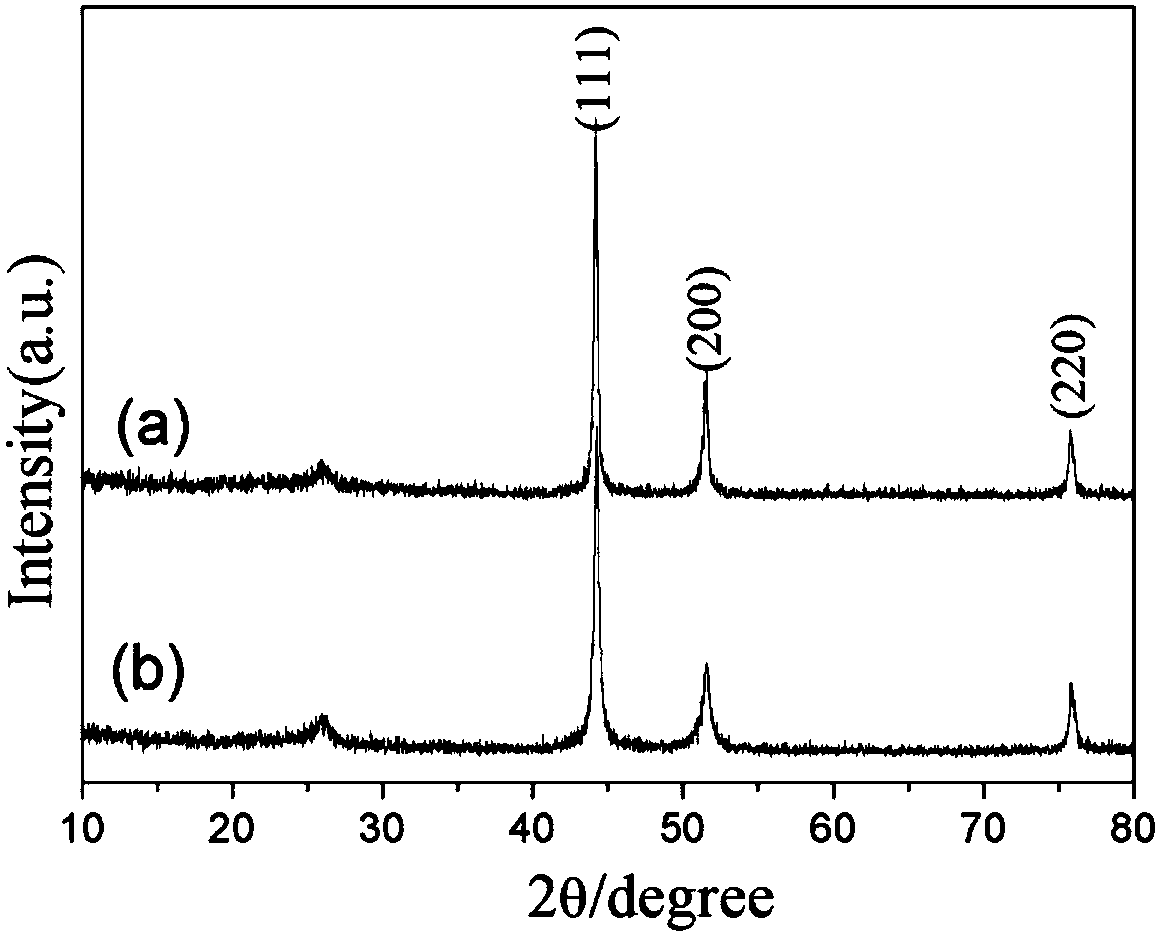

[0030] figure 1 The X-ray powder diffraction (XRD) ...

Embodiment 2

[0033] (1) Dissolve 0.414g of 1,3,5-benzenetricarboxylic acid and 0.24g of NaOH in 50mL of water to form a solution, and dissolve 0.714g of cobalt chloride hexahydrate in 50mL of water to form a solution. Mix and stir at room temperature for 1 hour at a stirring speed of 800r / min, then perform centrifugal washing at a rotating speed of 10000r / min, then put it in an oven, and dry at 80°C for 5 hours to obtain a Co-BTC precursor;

[0034] (2) Put the precursor obtained in step (1) into a quartz boat, use nitrogen as a protective gas in a tube furnace, heat up to 800°C at a heating rate of 5°C / min, keep it for 3 hours and start to cool down, After cooling to room temperature, the black magnetic cobalt / carbon composite was obtained.

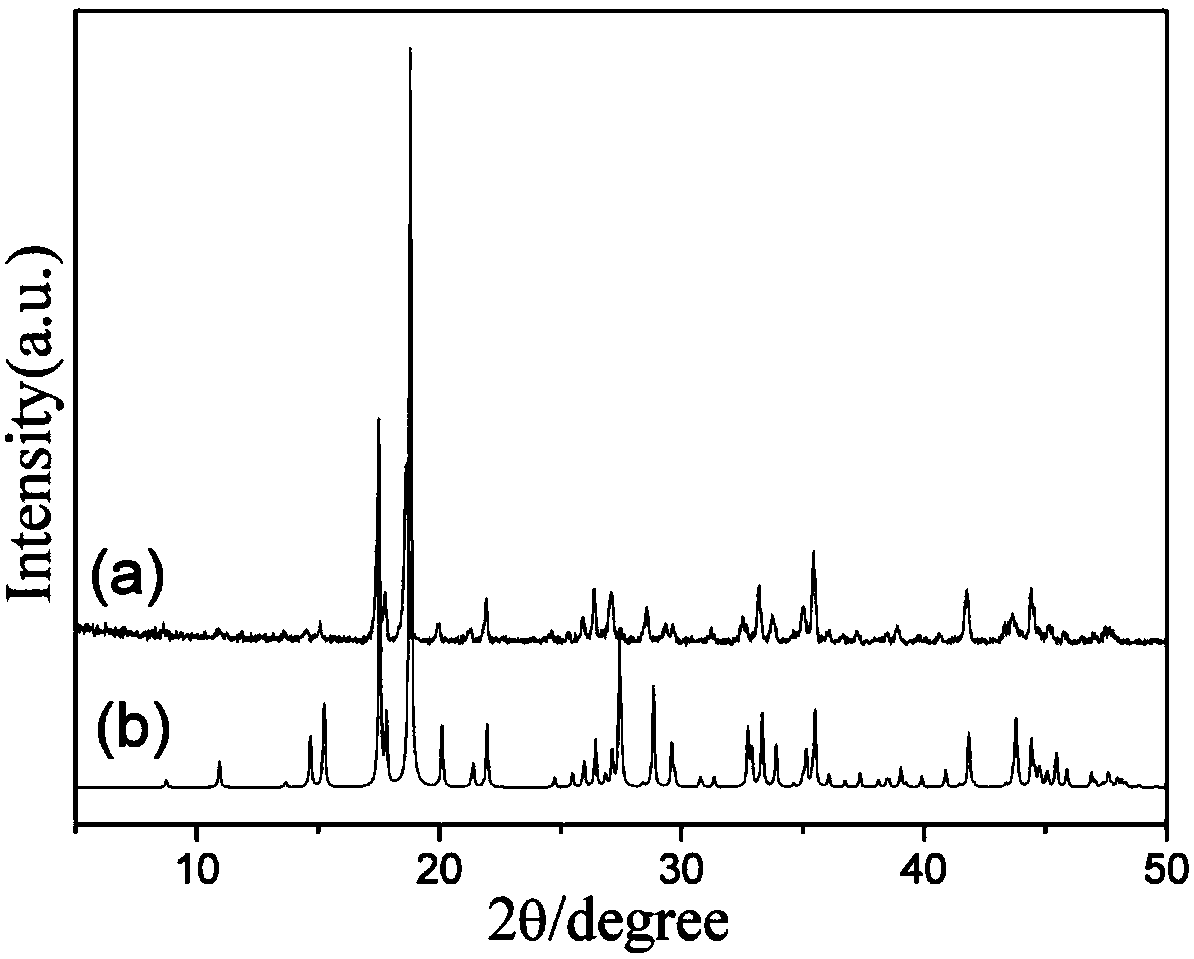

[0035] figure 2 The X-ray powder diffraction (XRD) spectrum of the cobalt-based metal-organic framework precursor prepared for this embodiment, from figure 2 It can be seen from the figure 2 The XRD patterns of simulated Co-BTC in b are consist...

Embodiment 3

[0040] The specific experimental procedure of the present embodiment is the same as in Example 1, except that 0.582g of cobalt nitrate hexahydrate is changed to 0.498g of cobalt acetate tetrahydrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com