Silica gel chromatographic packing as well as preparation method and application thereof

A technology of silica gel chromatography and silica gel, which is applied in the field of high-performance liquid chromatography packing materials, can solve the problems of unstable peak area, large baseline noise, and low column efficiency, and achieve the effects of simple preparation method, stable peak area, and high column efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

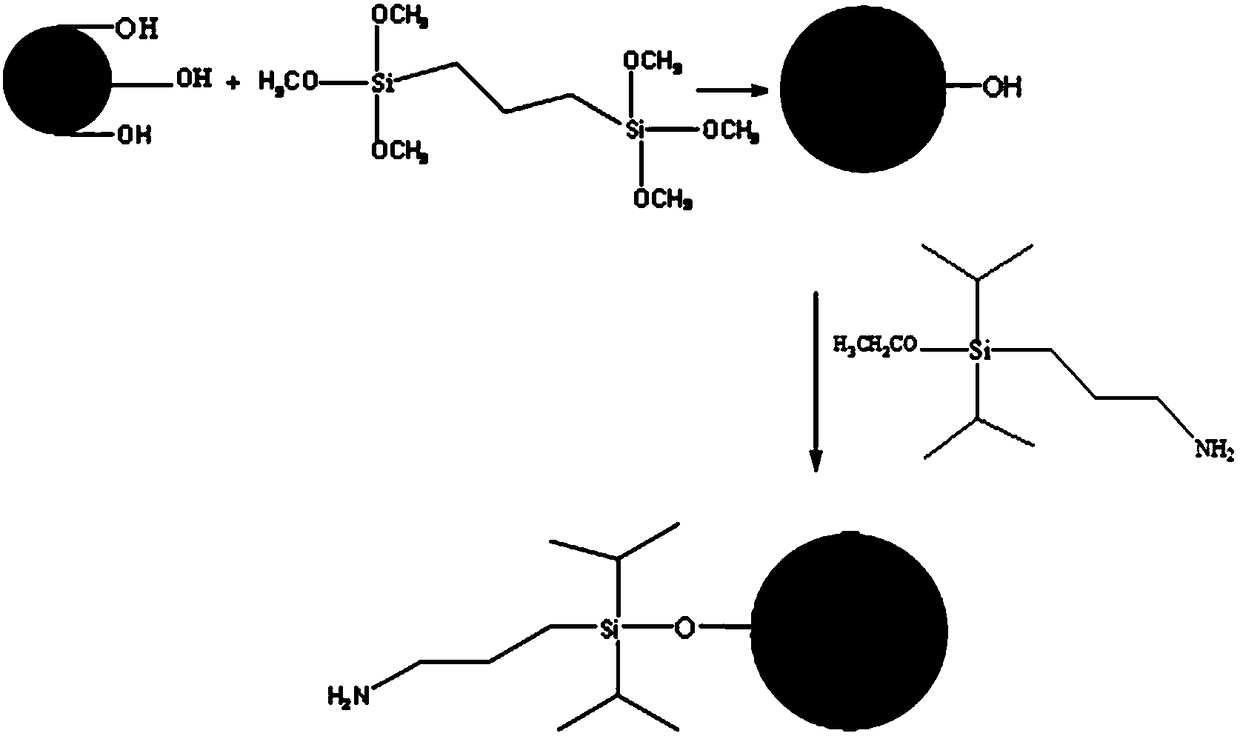

[0042] The present invention also provides a method for preparing the above silica gel chromatographic filler, which includes the following steps:

[0043] The silica gel is activated and pretreated to obtain activated silica gel with silanol on the surface;

[0044] The activated silica gel and the other silane are stirred and refluxed in an organic solvent, and the other silane is bonded to the surface of the activated silica gel to obtain a solution containing organic-inorganic hybrid silica gel; and

[0045] Aminopropyl silane is added to the solution for stirring and reflux reaction, and the aminopropyl silane is bonded to the surface of the organic-inorganic hybrid silica gel to obtain the silica gel chromatographic filler.

[0046] Specifically, the silica gel is preferably a fully porous spherical silica gel, and more preferably an ultra-high purity fully porous spherical silica gel for chromatography. The particle size of the raw material silica gel for activation is preferab...

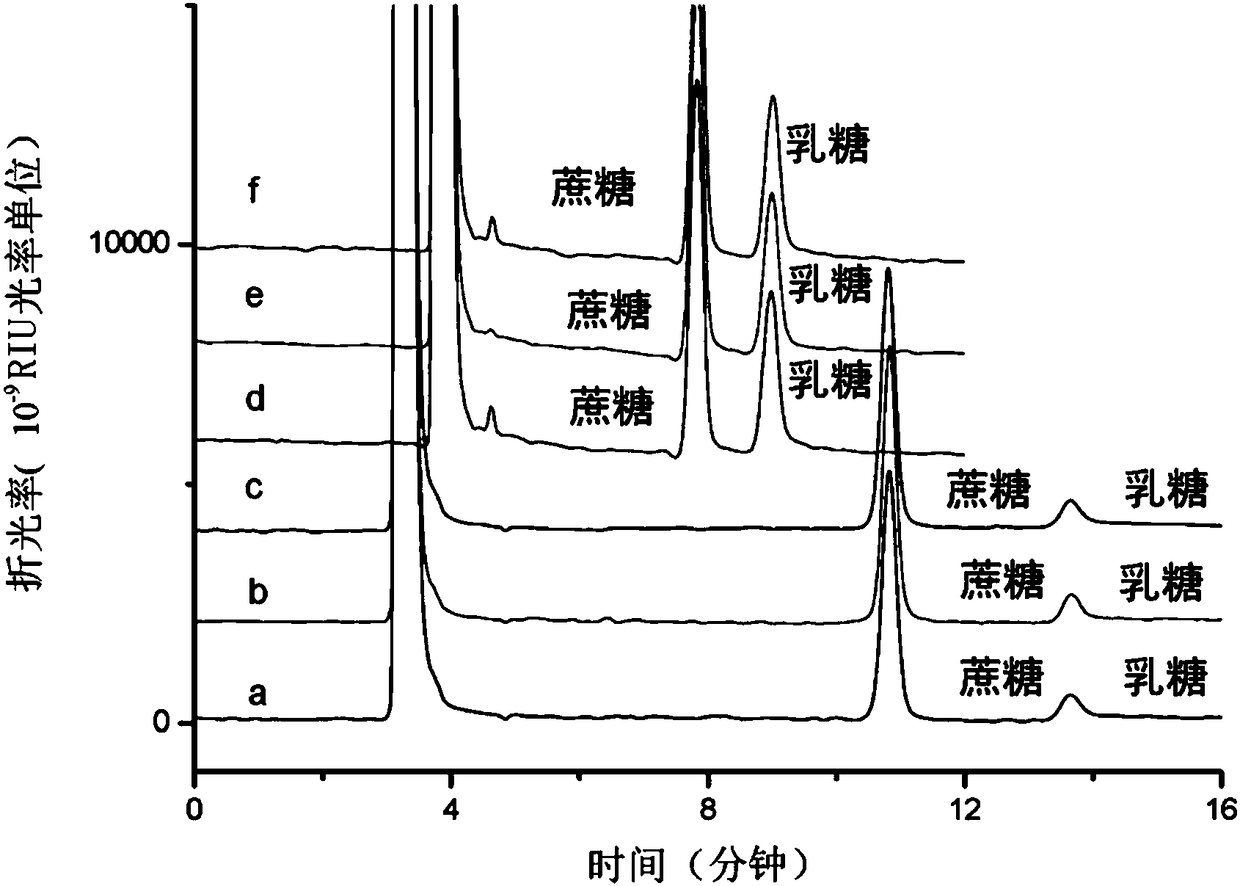

Embodiment 1

[0056] Example 1 Preparation of silica gel chromatography packing

[0057] figure 1 It is a schematic diagram of the method for preparing silica gel chromatography packing in Example 1. The specific preparation method includes the following steps:

[0058] (1) Add 100 g of silica gel (5 μm, purchased from Japan DAISO) into a 2L glass material reaction vessel, and add 1000 mL of distilled water, stir for 30 minutes, and filter, and repeat this step twice. Then add 1000 mL of 0.08% hydrofluoric acid aqueous solution with a mass ratio of 0.08%, stir for 24 hours and wash with distilled water to neutrality, finally add 1000 mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel A;

[0059] (2) Add the activated silica gel A prepared in "Step (1)" into the glass reaction vessel, and add 800 mL of dry anhydrous toluene solvent, stir well at 170 rpm, and then add 50.0 g of 1,2-bis(三甲 (Oxysilyl) propane B, use an electric heating mantle to heat to 110°C...

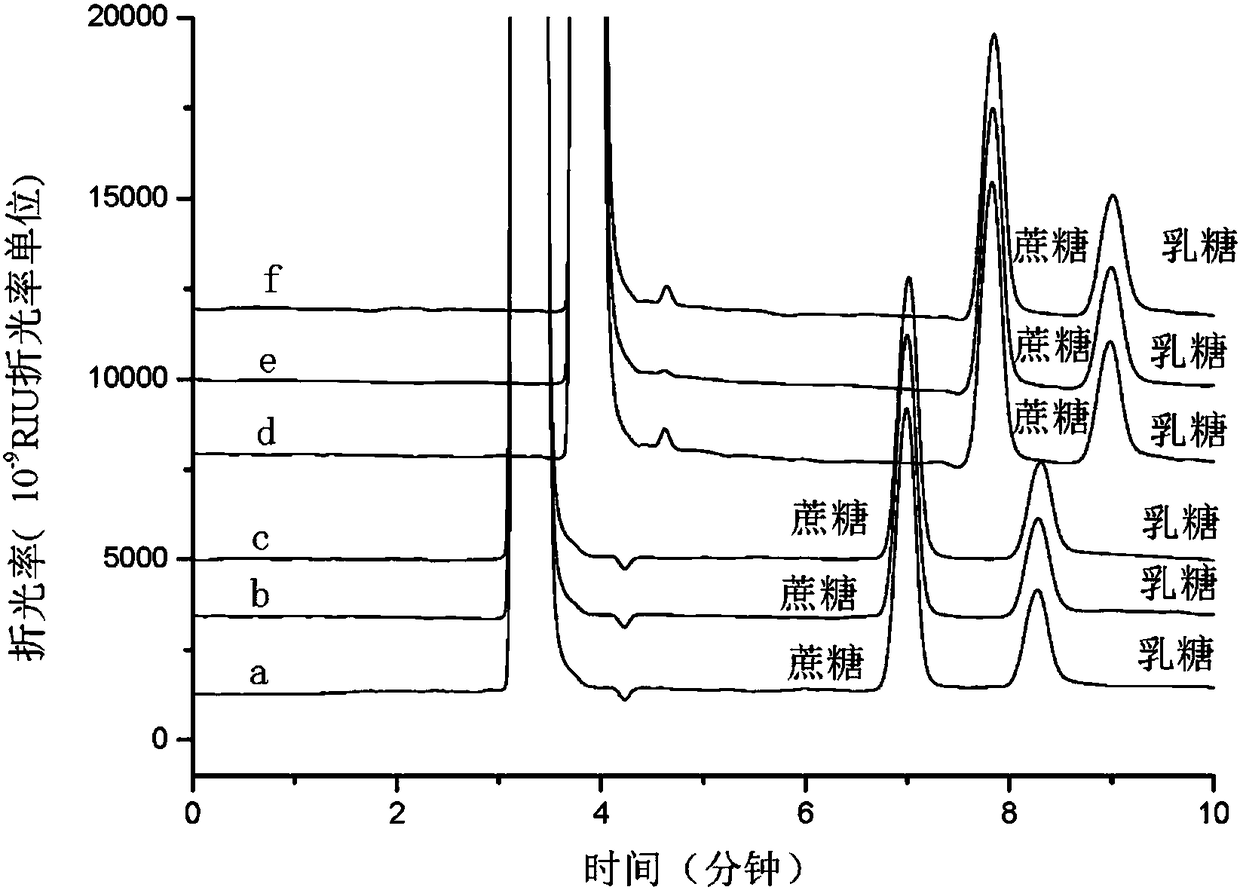

Embodiment 2

[0063] Example 2 Preparation of silica gel chromatography packing

[0064] (1) Add 100 g of silica gel (5 μm, purchased from Japan DAISO) into a 2L glass material reaction vessel, and add 1000 mL of distilled water, stir for 30 minutes, and filter, and repeat this step twice. Then add 1000 mL of 0.08% hydrofluoric acid aqueous solution with a mass ratio of 0.08%, stir for 24 hours and wash with distilled water to neutrality, finally add 1000 mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel;

[0065] (2) Add the activated silica gel prepared in "Step (1)" to the glass reaction vessel, and add 800 mL of dry anhydrous toluene solvent, stir well at 170 rpm, and then add 50.0 g of 1,2-bis(formaldehyde) (Oxysilyl)butane, heated to 110°C with an electric heating mantle, stirred and refluxed for 24 hours to obtain a solution containing organic-inorganic hybrid silica gel, wherein the organic-inorganic hybrid silica gel still contains part of unrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com