Fast-cured super-early strength polycarboxylate water reducer and preparation method thereof

A technology of strong polycarboxylic acid and water-reducing agent, applied in the field of building admixtures, can solve the problems of unmentioned quick-setting effect, difficult quality control, accelerated cement hydration, etc., to shorten the plastering and initial setting time, promote The effect of cement hydration reaction and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

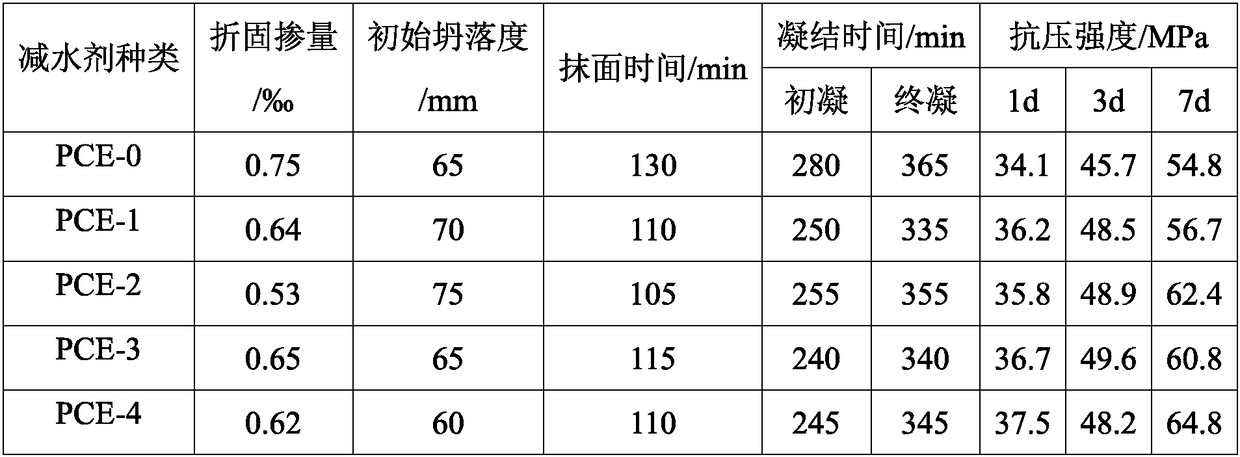

Examples

preparation example Construction

[0026] The preparation method of unsaturated alcohol amine ester small monomer in following embodiment comprises the steps:

[0027] (1) Acrylic acid and N, N-diethylethanolamine are joined in the reaction container that condensing device is housed in molar ratio 2.0: 1.2;

[0028] (2) Inject nitrogen gas while stirring, heat up to 55°C, add p-benzoquinone, stir for 20 minutes, p-quinone accounts for 1.0% of the total mass of acrylic acid and N,N-diethylethanolamine;

[0029] (3) Continue to heat up to 110°C, add phosphorous acid and react at a constant temperature for 4 hours, and phosphorous acid accounts for 1.2% of the total amount of acrylic acid and N,N-diethylethanolamine;

[0030] (4) After the reaction is stopped, the unreacted acrylic acid is distilled off under reduced pressure to obtain the small unsaturated alcohol amine ester monomer.

Embodiment 1

[0032] (1) Each raw material component is weighed by the following parts by weight: 200 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene ether with a molecular weight of 5000, 15 parts by weight of acrylic acid, 4 parts by weight of hydroxyethyl acrylate, unsaturated alcohol 5 parts by weight of urethane small monomer, 2 parts by weight of triplylamine, 0.75 parts by weight of ammonium persulfate, 0.6 parts by weight of sodium formaldehyde sulfoxylate, 0.06 parts by weight of ferrous sulfate, 0.8 parts by weight of thioglycolic acid, 8 parts by weight 32 wt% aqueous sodium hydroxide solution, 1 part by weight of trisodium phosphate, and the rest deionized water, adjusted to 50% solid content.

[0033] (2) acrylic acid and hydroxyethyl acrylate are dissolved in 15 parts by weight of deionized water to obtain the first solution; sodium formaldehyde sulfoxylate is dissolved in 30 parts by weight of deionized water to obtain the second solution; thioglycolic acid is dissolve...

Embodiment 2

[0038] (1) Take each raw material component by weight as follows: molecular weight is 180 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene base ether of 5500, 12 parts by weight of methacrylic acid, 5 parts by weight of hydroxypropyl acrylate, not 7 parts by weight of saturated alcohol amine ester small monomer, 3 parts by weight of tripropenylamine, 0.9 parts by weight of sodium persulfate, Brüggolit TM0.9 parts by weight of FF6, 0.08 parts by weight of ferrous nitrate, 0.4 parts by weight of mercaptoethanol, 9 parts by weight of 32 wt% sodium hydroxide aqueous solution, 3 parts by weight of trisodium phosphate, and the rest are deionized water, adjusted to 50% solid content.

[0039] (2) Dissolve methacrylic acid and hydroxypropyl acrylate in 12 parts by weight of deionized water to obtain the first solution; Brüggolit TM FF6 was dissolved in 30 parts by weight of deionized water to obtain the second solution; mercaptoethanol was dissolved in 30 parts by weight of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com