Rapid preparation method and application of antibacterial and deodorant polyester yarn

A polyester yarn, deodorizing technology, applied in the direction of rayon manufacturing, single-component polyester rayon, fiber chemical characteristics, etc., can solve the adverse effects on the environment and human health, weak Candida albicans effect, difficult to spin fine Denier and other problems, achieve efficient and durable antibacterial and deodorizing functions, overcome the lack of antibacterial and deodorizing functions, and broaden the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

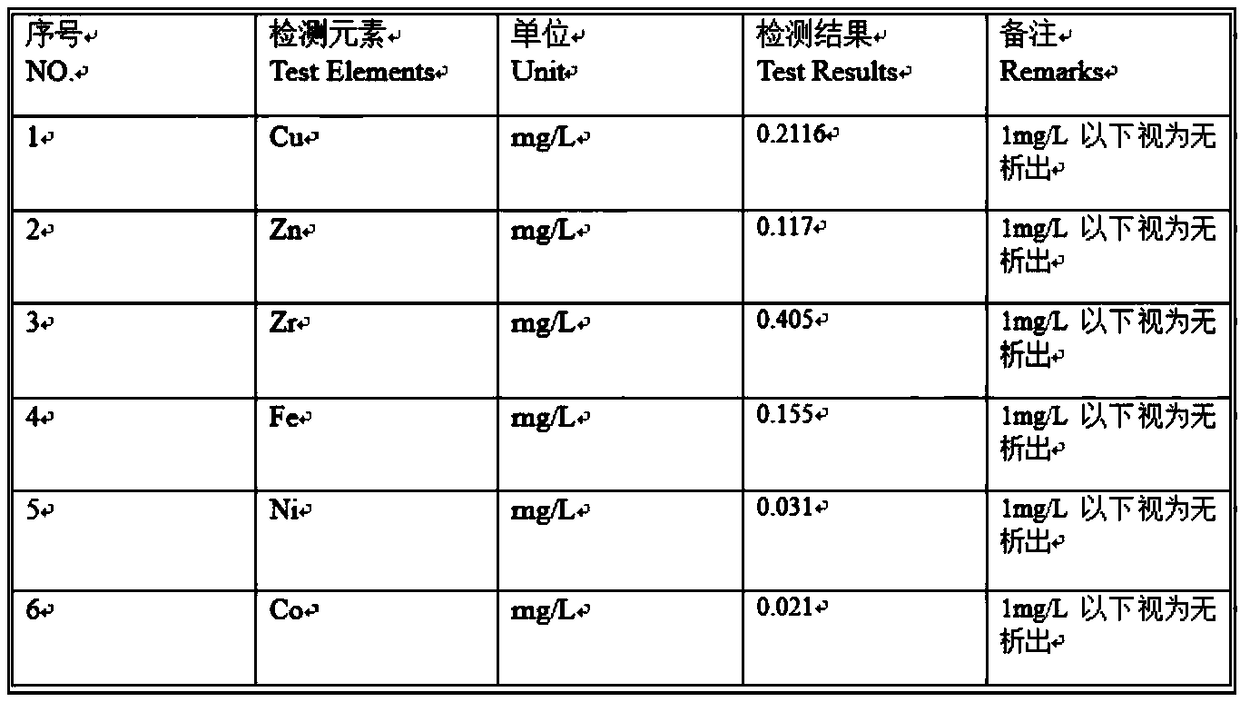

[0037] Dissolve copper acetate, zinc acetate, zirconium oxychloride, and PVP in water at a molar ratio of 1:1:0.5:0.01 to prepare a 0.05M aqueous dispersion; gradually add the aqueous solution to 1000 ml of ethylene glycol under vigorous stirring Put it in a microwave oven, react at 160°C for 40 minutes, and cool to obtain a self-assembled dispersion of nano-metal oxides with a crystallite size below 5nm; evaporate the water in it in a vacuum until the content is below 0.5%. Add formic acid, ethylene glycol and catalyst into the reaction kettle, seal it and replace it with nitrogen for 3 times, and perform esterification at 2.5MPa and 220°C for 2 hours; then add the nanometer metal oxide self-assembled dispersion to the In the polycondensation reactor, turn on the vacuum system, raise the temperature to 280°C to start polycondensation, keep the system pressure below 150Pa, and the reaction time is 3.5h; after the reaction, the product is sprayed, cooled, and formed to obtain an...

Embodiment 2

[0040] Dissolve zirconium acetate, zinc acetate, sodium silicate, and polyethylene glycol in water at a molar ratio of 1:1:0.5:0.05 to prepare a 0.05M aqueous dispersion; gradually add the aqueous solution to 1000 ml of ethylene glycol under vigorous stirring alcohol; put it in a microwave oven, react at 150°C for 50 minutes, and cool to obtain a self-assembled dispersion of nano-metal oxides with a crystallite size below 5nm; evaporate the water in it under vacuum until the content is below 0.5%. Add phthalic acid, ethylene glycol and catalyst into the reaction kettle, seal it and replace it with nitrogen for 3 times, esterify at 2.5MPa and 220°C for 2h; then add nanometer metal oxide self-assembled and dispersed Put the body into the polycondensation reactor, turn on the vacuum system, raise the temperature to 280°C to start polycondensation, keep the system pressure below 150Pa, and the reaction time is 3.5h; after the reaction, the product is sprayed, cooled, and sliced t...

Embodiment 3

[0042] Dissolve copper nitrate, zinc nitrate, urea, and polyacrylamide in water at a molar ratio of 1:1:0.01:0.05 to prepare a 0.05M aqueous dispersion; gradually add the aqueous solution to 1000 ml of ethylene glycol under vigorous stirring; Put it in a microwave oven, react at 160°C for 30 minutes, and cool to obtain a self-assembled dispersion of nano-metal oxides with a crystallite size below 5nm; evaporate the water in it in a vacuum until the content is below 0.5%. Add ethylene glycol and catalyst to the reaction kettle, seal it and replace it with nitrogen for 3 times, and esterify at 2.5MPa and 220°C for 2h; then add the nanometer metal oxide self-assembled dispersion to the In the polycondensation reactor, turn on the vacuum system, raise the temperature to 280°C to start polycondensation, keep the system pressure below 150Pa, and the reaction time is 3.0h; after the reaction, the product is sprayed, cooled, and formed to obtain antibacterial and deodorizing polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallite size | aaaaa | aaaaa |

| Crystallite size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap