Copper-ion-imprinted composite adsorbing material and preparation method thereof

A technology of composite adsorption materials and copper ions, which is applied in chemical instruments and methods, adsorption of water/sewage treatment, alkali metal compounds, etc., can solve the problems of decreased adsorption capacity of metal ions, improve stability, increase adsorption, and improve acid resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

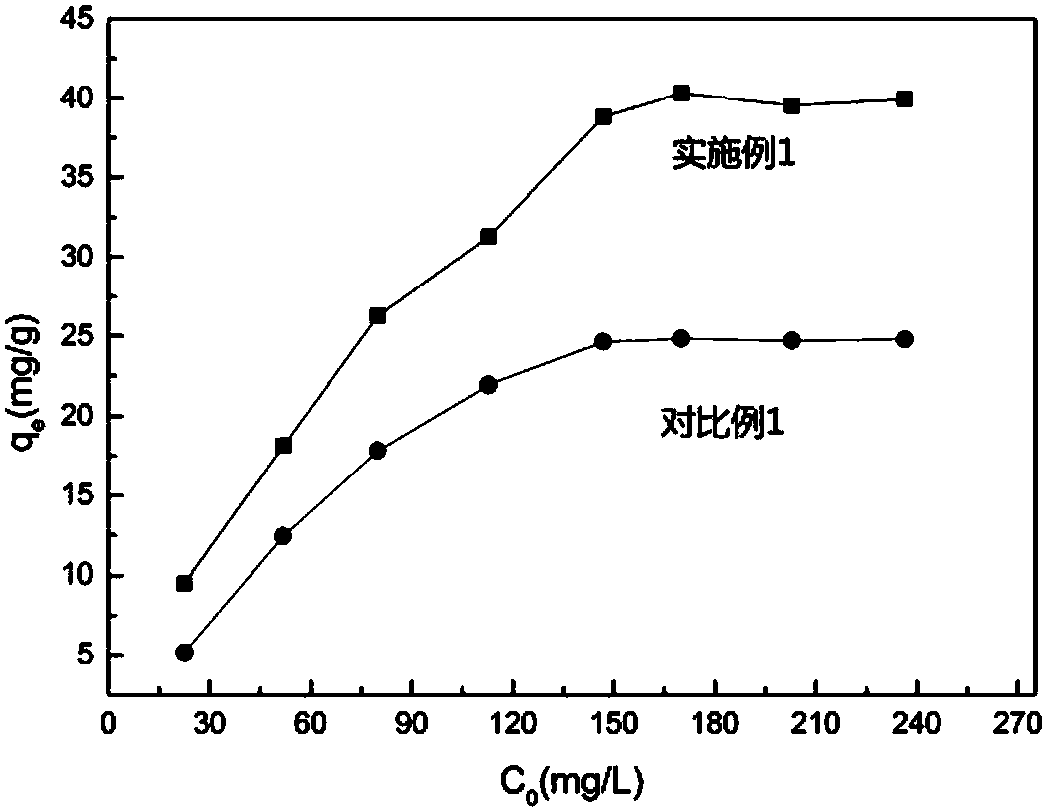

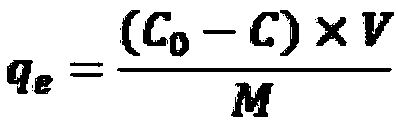

Embodiment 1

[0040] (1) 0.9g chitosan was dissolved in 30mL, 1% (w / v) acetic acid solution, and ultrasonically degassed for 30min;

[0041] (2) 0.3g sodium carboxymethylcellulose is dissolved in 60mL, 0.5mol / L sodium hydroxide solution to obtain sodium carboxymethylcellulose / sodium hydroxide composite coagulation liquid;

[0042] (3) drip the chitosan acetic acid solution that step (1) makes into the sodium carboxymethylcellulose / sodium hydroxide composite coagulation liquid that step (2) makes with syringe, obtain even and complete chitosan / Sodium carboxymethylcellulose composite gel microspheres, let stand for 30min, then take out the gel microspheres and wash with water until neutral;

[0043] (4) Place the gel microspheres prepared in step (3) in 40 mL of an aqueous solution containing 0.25 g of copper chloride, shake the imprint at 30 ° C for 12 h, and then wash with water to remove residual Cu 2+ ;

[0044] (5) Place the gel microspheres prepared in step (4) in 40 mL of 0.66% glutar...

Embodiment 2

[0061] (1) 0.9g chitosan was dissolved in 30mL, 1% (w / v) acetic acid solution, and ultrasonically degassed for 30min;

[0062] (2) 0.3g sodium carboxymethylcellulose is dissolved in 60mL, 0.5mol / L sodium hydroxide solution to obtain sodium carboxymethylcellulose / sodium hydroxide composite coagulation liquid;

[0063] (3) drip the chitosan acetic acid solution that step (1) makes into the sodium carboxymethylcellulose / sodium hydroxide composite coagulation liquid that step (2) makes with syringe, obtain even and complete chitosan / Sodium carboxymethylcellulose composite gel microspheres, let stand for 30min, then take out the gel microspheres and wash with water until neutral;

[0064] (4) Place the gel microspheres prepared in step (3) in 40 mL of an aqueous solution containing 0.17 g of copper nitrate, shake the imprint at 30 ° C for 12 h, and then wash with water to remove residual Cu 2+ ;

[0065] (5) Place the gel microspheres prepared in step (4) in 40 mL of 1.19% gluta...

Embodiment 3

[0069] (1) 0.9g chitosan was dissolved in 30mL, 1% (w / v) acetic acid solution, and ultrasonically degassed for 30min;

[0070] (2) 0.3g sodium carboxymethylcellulose is dissolved in 60mL, 0.5mol / L sodium hydroxide solution to obtain sodium carboxymethylcellulose / sodium hydroxide composite coagulation liquid;

[0071] (3) drip the chitosan acetic acid solution that step (1) makes into the sodium carboxymethylcellulose / sodium hydroxide composite coagulation liquid that step (2) makes with syringe, obtain even and complete chitosan / Sodium carboxymethylcellulose composite gel microspheres, let stand for 30min, then take out the gel microspheres and wash with water until neutral;

[0072] (4) Place the gel microspheres prepared in step (3) in 40 mL of an aqueous solution containing 0.42 g of copper sulfate, shake the imprint at 30 ° C for 12 h, and then wash with water to remove residual Cu 2+ ;

[0073] (5) Place the gel microspheres prepared in step (4) in 40 mL of 1.46% gluta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com