Method for treating caprolactam oximation wastewater

A caprolactam oxime and biochemical treatment technology, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, anaerobic digestion treatment, etc. The effect of low cost and reduced processing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

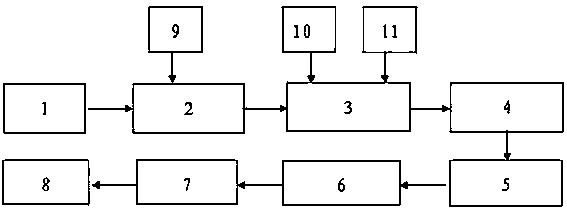

Image

Examples

Embodiment 1

[0022] (1) Caprolactam oximation wastewater 1000L, water inlet conditions: pH 9-14, temperature 30-60°C, add sulfuric acid and stir or blow evenly to adjust the pH of the wastewater to 4.5.

[0023] (2) Add a strong oxidizing agent to the wastewater after pH adjustment, the dosage of perchloric acid is 0.05%, and the dosage of 30% hydrogen peroxide is 50ppm, and it is fully stirred or aerated until uniform.

[0024] (3) at 5m 3 h -1 The volume flow rate enters the fixed-bed reactor, and the catalytic oxidation treatment is carried out through the prepared Fe / activated carbon catalyst with a loading capacity of 5%, and the treated wastewater enters the biochemical treatment system.

[0025] (4) The primary aerobic treatment pool controls the temperature at 20-40°C, pH at 7.2, dissolved oxygen concentration at 3.6 mg / L, and aeration time of 20 hours to further oxidize residual organic matter and decompose organic nitrogen into ammoniacal nitrogen and Nitrate nitrogen.

[0026...

Embodiment 2

[0028] (1) Caprolactam oximation wastewater 1000L, water inlet conditions: pH 9-14, temperature 30-60°C, add sulfuric acid and stir or blow evenly to adjust the pH of the wastewater to 5.2.

[0029] (2) Add a strong oxidizing agent to the wastewater after pH adjustment, the dosage of sodium chlorate is 0.1%, the dosage of 30% hydrogen peroxide is 75ppm, fully stir or aerate until uniform.

[0030] (3) at 5m 3 h -1 The volume flow rate enters the fixed-bed reactor, and the prepared manganese / alumina catalyst with a loading capacity of 3% is used for catalytic oxidation treatment, and the treated wastewater enters the biochemical treatment system.

[0031] (4) In the aerobic aeration stage, the temperature of the SBR tank is controlled at 20-40°C, the pH is 7.6, the dissolved oxygen concentration is 3.3 mg / L, and the aeration time is 25 hours, so as to further oxidize the residual organic matter and decompose the organic nitrogen into ammoniacal nitrogen and nitrate nitrogen. ...

Embodiment 3

[0034] (1) Caprolactam oximation wastewater 1000L, water inlet conditions: pH 9-14, temperature 30-60°C, add sulfuric acid and stir or blow evenly to adjust the pH of the wastewater to 5.0.

[0035] (2) Add a strong oxidant after adjusting the pH of the wastewater, the dosage of ammonium persulfate is 0.15%, the dosage of 30% hydrogen peroxide is 100ppm, fully stir or aerate until uniform.

[0036] (3) at 5m 3 h -1 The volume flow rate enters the fixed-bed reactor, and the catalytic oxidation treatment is carried out through the prepared Fe / ZSM-5 catalyst with a loading capacity of 2%, and the treated wastewater enters the biochemical treatment system.

[0037] (4) The primary oxidation ditch controls the temperature at 20-40°C, pH at 8.0, dissolved oxygen concentration at 3.3 mg / L, and aeration time of 25 hours to further oxidize residual organic matter and decompose organic nitrogen into ammoniacal nitrogen and nitrate nitrogen .

[0038] (5) The concentration of microorgan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com