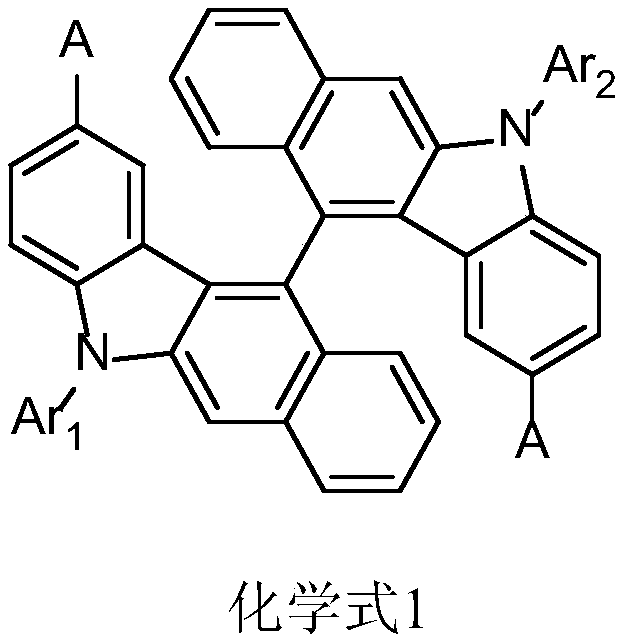

Organic electroluminescent material, preparation method thereof and organic electroluminescent device

An electroluminescent material and electroluminescent technology, applied in the direction of luminescent materials, electro-solid devices, electrical components, etc., to achieve the effects of improving current characteristics, long device life, and high electron transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

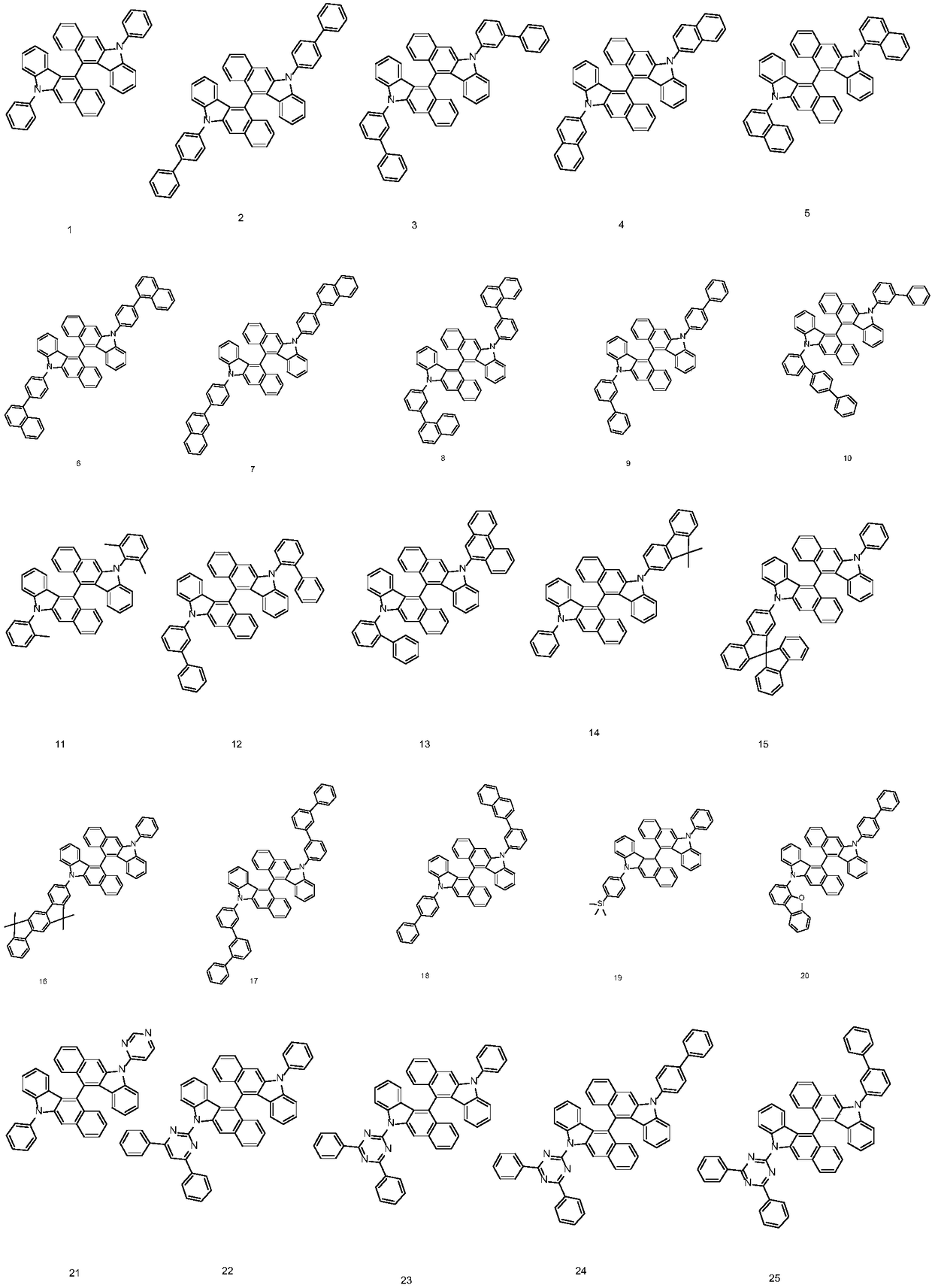

Examples

Synthetic example

[0047] Synthesis of intermediate e:

[0048]

[0049] Compound a (21g, 52.6mmol) was dissolved in tetrahydrofuran (300mL), hexane solvent was added dropwise at -78°C, 2.5M n-butyllithium (25.2mL, 63.1mmol) was stirred for one hour. Trimethyl borate (18.2 mL, 79 mmol) was slowly added dropwise and then stirred for 2 h. After neutralization by dropwise addition of 2M hydrochloric acid, the product was extracted with ethyl acetate and water. Recrystallization from dichloromethane and hexane gave compound b (8.4 g, 47%).

[0050] Compound b (85.8 g, 251 mmol), compound c (50.7 g, 251 mmol), tetrakistriphenylphosphine palladium (11 g, 10 mmol) and potassium carbonate (84.2 g, 609 mmol) were dissolved in toluene (1 L) / EtOH (200 mL) / distilled water (200 mL) and then heated at 90° C. for 2 hours. The organic layer was triturated with methanol after distillation under reduced pressure. The obtained solid was dissolved in dichloromethane, filtered through silica gel, and tritura...

Embodiment 1

[0158] [Example 1] Green light organic electroluminescent device (phosphorescent host)

[0159] First, 60nm (N1,N1'-([1,1'-biphenyl]-4,4'-diyl)bis(N1-(naphthalen-1-yl)-N4,N4- diphenylbenzene-1,4-diamine) to form a hole injection layer. The above hole injection layer is vapor-deposited with N,N'-diphenyl-N,N'-(1-naphthyl)-1,1'-biphenyl- 4,4'-Diamine (NPD) 60nm, compound 1 of the present invention and doped Ir(ppy) 3 [Tris(2-phenylpyridine)iridium] 95:5 weight ratio evaporation 30nm, bis(2-methyl-8-hydroxyquinoline-N1,O8)-(1,1'-biphenyl-4- Hydroxy) aluminum (BAlq) hole blocking layer vapor deposition 10nm, vapor deposition electron transport layer 8-hydroxyquinoline aluminum (Alq 3 ) 40nm, evaporated LiF 0.2nm to form the electron injection layer, evaporated Al 150nm to form the cathode.

[0160] [Example 2]-[Example 42] Green light organic electroluminescent device

[0161] Green-light host material of the light-emitting layer Except that the compound described in Table 1 w...

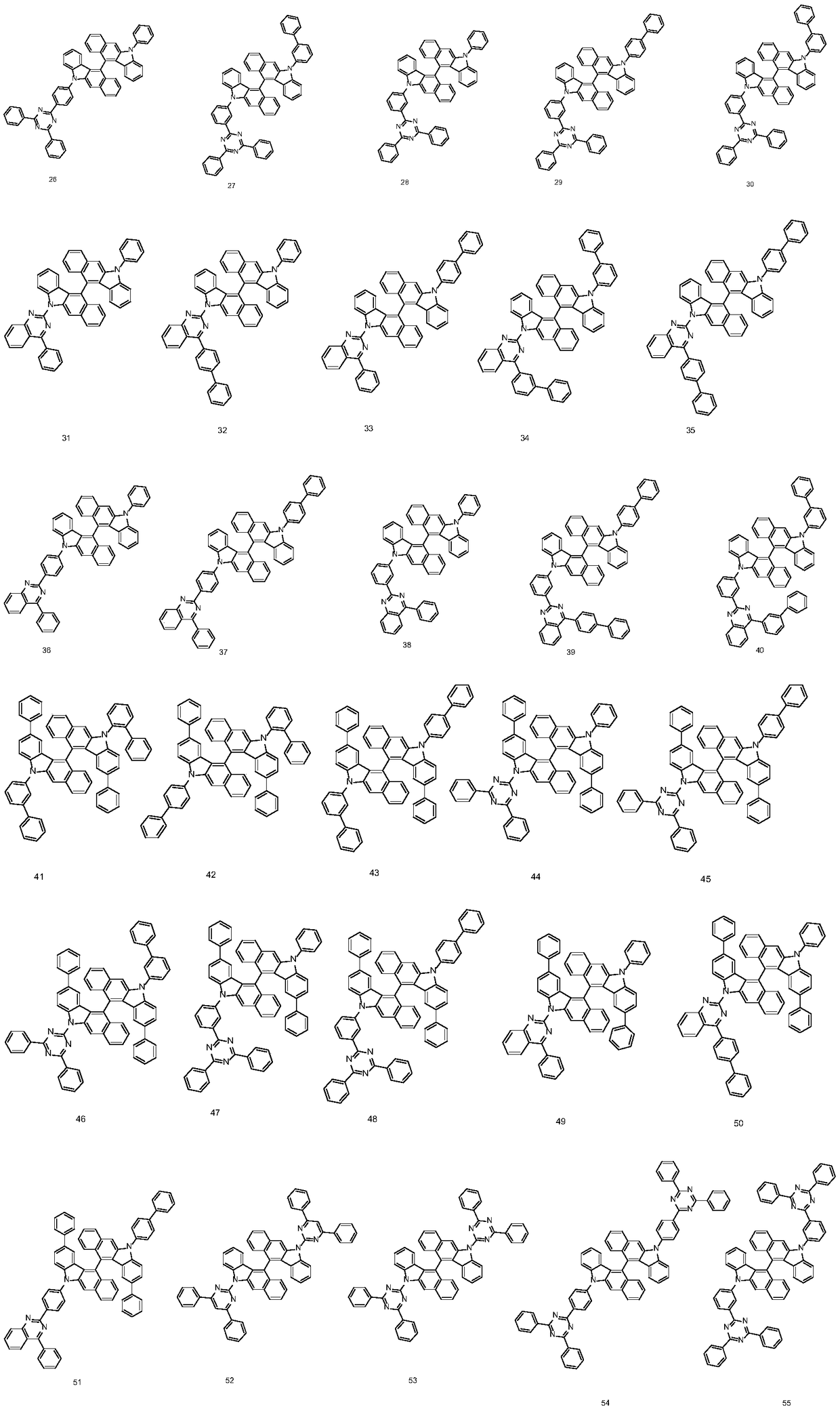

Embodiment 43

[0171] [Example 43] Red photoelectron light-emitting device (phosphorescent host)

[0172] First, 2-TNATA was vapor-deposited on the ITO layer (anode) formed on the glass substrate to a thickness of 60nm to form a hole injection layer, and a hole-transport layer NPD was vapor-deposited on the hole injection layer to a thickness of 60nm. The compound 31 and the dopant substance (piq) of host material Table 2 are vapor-deposited on the hole transport layer 2 Ir(acac)[bis-(1-phenylisoquinolyl)iridium(III)acetylacetonate] / 95:5 weight ratio 30nm thickness, evaporated hole blocking layer BAlq 10nm thickness, evaporated electron transport layer Alq 3 40nm thickness, vapor-deposited electron injection layer LiF 0.2nm thickness, vapor-deposited Al 150nm thickness to form the cathode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com