Alkane dehydrogenation catalyst and preparation method thereof

A technology of alkane dehydrogenation and catalyst, which is applied in the direction of catalysts, carbon compound catalysts, chemical instruments and methods, etc. It can solve the problems of low conversion rate, short life, poor stability of low carbon chains, etc., and achieve reduced carbon deposition and high stability , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

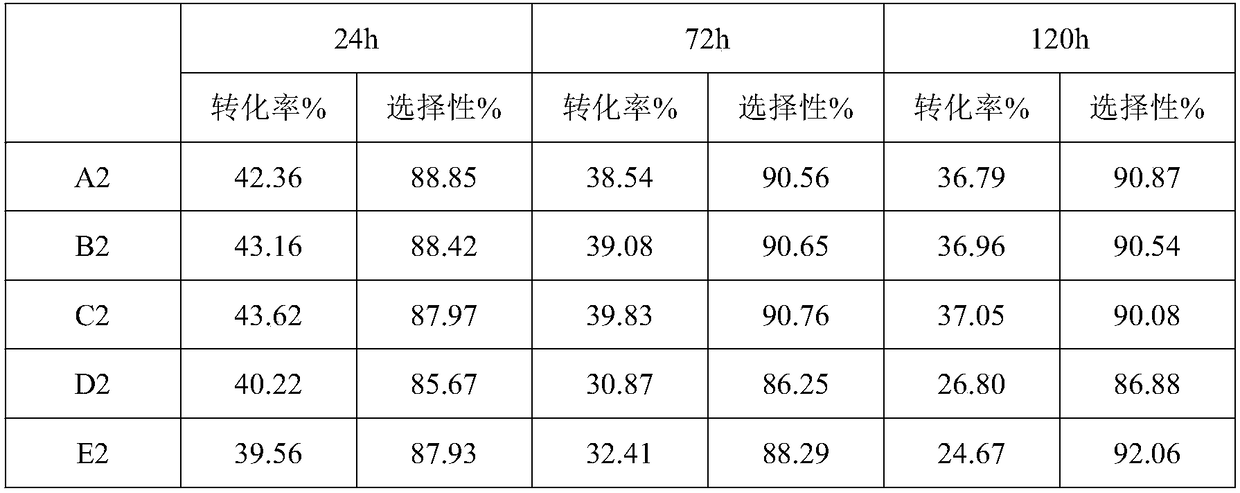

Examples

Embodiment 1

[0029] Carrier preparation: mix 50g of sieved 70-120μm pseudo-boehmite raw powder with 62g of 5% dilute hydrochloric acid solution in a tank at 70°C to form a sol, and shape it in an oil ammonia column to obtain pellets , dried at 120°C, then roasted at 900°C for 4 hours, sieved after cooling The small ball, namely the carrier A1.

[0030] Catalyst preparation: Take 20 g of the A1 alumina support pellets prepared above and place them in an impregnator. Take 4ml of chloroplatinic acid aqueous solution containing platinum 0.01g / ml, 3.25ml of tin protochloride aqueous solution containing 0.005g / ml of tin, 0.53ml of potassium nitrate solution containing 0.01g / ml of potassium, add 0.33g of 2-propenyl acrylic acid , and then add 8.27g of deionized water to prepare an impregnating solution, and impregnate the alumina carrier at 60°C for 2h. Then dry at 100°C for 2h, and bake at 550°C for 4h to obtain catalyst A2

Embodiment 2

[0032] Carrier preparation: Mix 38g of 70-120μm γ-alumina raw powder sieved with 50g of 5% dilute hydrochloric acid solution in a tank at 60°C to form a sol, and shape it in an oil ammonia column to obtain pellets. Dry at 140°C, then bake at 1000°C for 6 hours, sieve after cooling The pellets are obtained as carrier B1.

[0033] Catalyst preparation: Take 20 g of the carrier B1 alumina pellets prepared above and put them in an impregnator. Get 6ml of chloroplatinic acid aqueous solution containing platinum 0.01g / ml, 5.00ml of tin protochloride aqueous solution containing 0.005g / ml of tin, 0.80ml of potassium nitrate solution containing potassium 0.01g / ml, add 0.48g of pyruvic acid, and then add 4.20 g of deionized water was prepared as an impregnation solution, and the alumina carrier was impregnated at 40° C. for 2 hours. Then it was dried at 80°C for 2 hours and calcined at 600°C for 6 hours to obtain catalyst B2.

Embodiment 3

[0035] Carrier preparation: Mix 52g of 70-120μm diaspore raw powder and 67g of 5% dilute hydrochloric acid solution in a tank at 80°C to form a sol, and shape it in an oil ammonia column to obtain pellets , dried at 130°C, then calcined at 1100°C for 5h, cooled and sieved The pellets are the carrier C1.

[0036] Catalyst preparation: Take 20 g of the carrier C1 alumina pellets prepared above and place them in an impregnator. Get 6ml of chloroplatinic acid aqueous solution containing platinum 0.01g / ml, 5.20ml of tin protochloride aqueous solution containing 0.005g / ml tin, 1.00ml of potassium nitrate solution containing potassium 0.01g / ml, add 0.62g butanonic acid, and then Add 4.79 g of deionized water to prepare an impregnating solution, and impregnate the alumina carrier at 50° C. for 3 hours. Then, it was dried at 80°C for 3 hours and calcined at 500°C for 8 hours to obtain catalyst C2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com