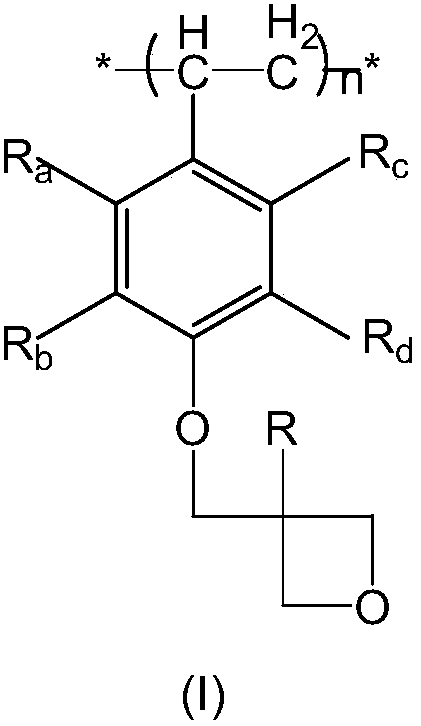

Photoresist composition comprising poly (p-hydroxy styrene) oxetane resin used as film formation resin

A technology of film-forming resin and composition, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, and can solve problems such as complex process flow, wide molecular weight distribution of products, and few types of photoresist negatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0155] The present invention will be further described below in conjunction with the examples, but they should not be construed as limiting the protection scope of the present invention.

[0156] The characterization and detection methods involved in the following examples are as follows:

[0157] 1. Infrared Spectroscopy Characterization Method

[0158] Infrared spectrum was measured by Shimadzu IRAffinity Fourier Transform Infrared Spectrometer with a scanning range of 4000-400cm -1 , the sample was processed by KBr pellet method.

[0159] 2. 1 H NMR spectrum characterization method

[0160] 1 H NMR was measured with a Bruker Avame PRX400 nuclear magnetic resonance instrument, the chemical shift was expressed in ppm, the solvent was deuterated chloroform, the internal standard was tetramethylsilane, the scan width was 400 MHz, and the number of scans was 16 times.

[0161] 3. Determination method of ultraviolet absorption spectrum

[0162] Using acetonitrile as a solve...

preparation Embodiment 1

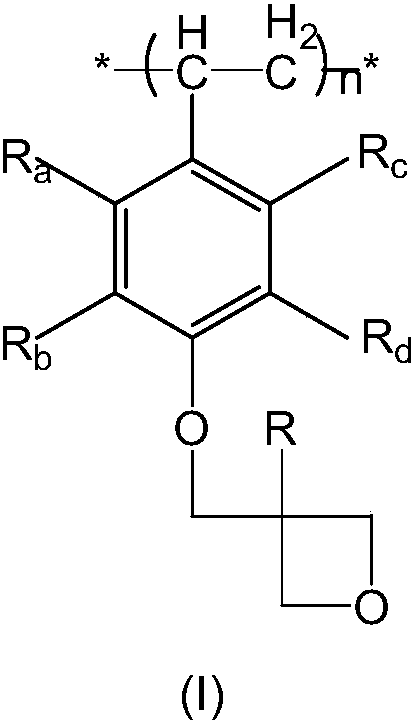

[0165] Preparation Example 1: Polymer 1

[0166]

[0167] Take 50mL of acetone as a solvent, add 13.4g of poly-m-methyl-p-hydroxystyrene (number-average molecular weight 2680, n=20) (0.1mol repeating unit) to the solvent, stir electrically, feed nitrogen, add potassium carbonate 8.28g ( 0.06mol), the reaction temperature of the resulting mixture is controlled at 60°C, and 19.2g 3-chloromethyloxetane (0.18mol) is slowly added dropwise through a constant pressure dropping funnel, and the dropwise addition is completed within 0.5h, and then the The resulting reaction mixture was reacted at 60° C. for 12 h. After the reaction was completed, 100 mL of dichloromethane was added, extracted with water, and the organic layer was extracted with MgSO 4 After drying, the solvent was evaporated under reduced pressure to obtain a solid product, which was washed three times with water, filtered and dried to obtain a product which was analyzed as the title compound.

[0168] The NMR data...

preparation Embodiment 2

[0171] Preparation Example 2: Polymer 2

[0172]

[0173] Take 50 mL of acetone as the solvent, add 17.6 g of poly-2,3,5,6-tetramethyl-p-hydroxystyrene (number-average molecular weight 3520, n=20) (0.1 mol repeating unit) to the solvent, stir electrically, and feed Nitrogen, add potassium carbonate 8.28g (0.06mol), the reaction temperature of the gained mixture is controlled at 60 ℃, slowly add 21.6g 3-methyl-3-chloromethyl oxetane ( 0.18mol), the dropwise addition was completed within 0.5h, and then the resulting reaction mixture was reacted at 60°C for 12h. After the reaction was completed, 100 mL of dichloromethane was added, extracted with water, and the organic layer was extracted with MgSO 4 After drying, the solvent was evaporated under reduced pressure to obtain a solid product, which was washed three times with water, filtered and dried to obtain a product which was analyzed as the title compound.

[0174] The NMR data of the resulting product are as follows (d-C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com