A kind of sewage treatment agent and preparation method thereof

A technology of sewage treatment agent and solvent, applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. High, secondary pollution of reagent components, etc., to achieve good stability, good anti-rotation effect, and the effect of enhancing cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

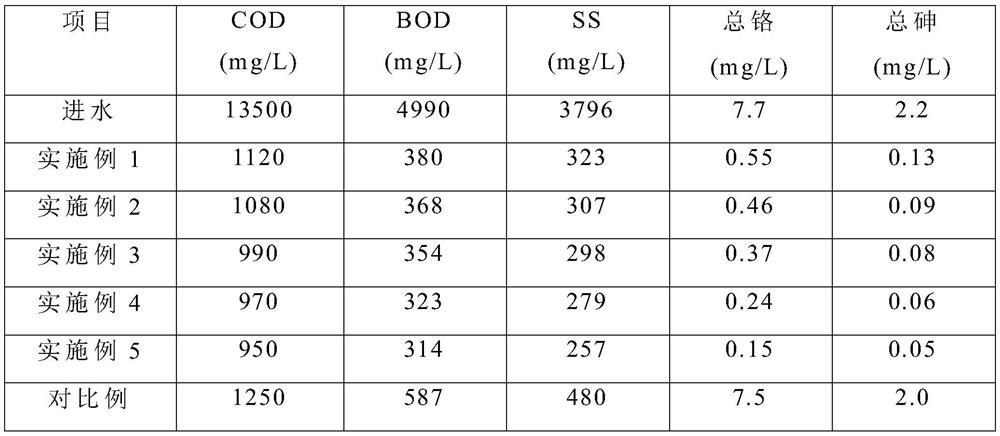

Examples

Embodiment 1

[0034] A preparation method of sewage treatment agent, comprising the steps of:

[0035] 1) Surface modification of polymeric aluminum iron silicate: add 30 g of polymeric aluminum iron silicate to 100 g of ethanol, then add 15 g of 3-chloropropyltriethoxysilane, stir and react at 40 ° C for 6 hours, and remove the solvent by rotary evaporation can;

[0036] 2) Amino starch-modified surface-modified polyaluminum iron silicate: add 30 g of the surface-modified polyaluminum iron silicate prepared in step 1) into 100 g of isopropanol, and add 10 g of amino starch to it, and stir at 40°C Reacted for 4 hours, and the solvent was removed by rotary evaporation;

[0037] 3) Dimethyl-vinyl phosphate transesterification: Add 30 g of amino starch modified surface-modified polyaluminum iron silicate prepared in step 2) into 100 g of acetone, then add 15 g of dimethyl-vinyl phosphate, KOH 5g and 5g of chloranil, react at 70°C for 10 hours, then filter, wash with water for 3 times, absorb...

Embodiment 2

[0042] A preparation method of sewage treatment agent, comprising the steps of:

[0043]1) Surface modification of polyaluminum iron silicate: add 35 g of polyaluminum iron silicate into 110 g of isopropanol, then add 18 g of 3-chloropropyltriethoxysilane, stir and react at 42°C for 6.5 hours, and spin evaporate Just remove the solvent;

[0044] 2) Amino starch-modified surface-modified polyaluminum iron silicate: add 35 g of the surface-modified polyaluminum iron silicate prepared in step 1) into 115 g of isopropanol, and add 13 g of amino starch to it, and stir at 45°C Reacted for 4.5 hours, and the solvent was removed by rotary evaporation;

[0045] 3) Dimethyl-vinyl phosphate transesterification: add 35 g of amino starch modified surface-modified polyaluminum iron silicate prepared in step 2) into 115 g of acetone, then add 17 g of dimethyl-vinyl phosphate, NaOH 6g and 6.5g of l,4-naphthoquinone were reacted at 75°C for 10.5 hours, then filtered, washed with water for 4 ...

Embodiment 3

[0050] A preparation method of sewage treatment agent, comprising the steps of:

[0051] 1) Surface modification of polyaluminum iron silicate: add 40 g of polyaluminum iron silicate to 135 g of n-butanol, then add 20 g of 3-chloropropyltriethoxysilane, stir and react at 45 °C for 7 hours, and spin evaporate Just remove the solvent;

[0052] 2) Amino starch-modified surface-modified polyaluminum iron silicate: add 40 g of the surface-modified polyaluminum iron silicate prepared in step 1) into 136 g of isopropanol, and add 15 g of amino starch to it, and stir at 48°C Reacted for 5 hours, and the solvent was removed by rotary evaporation;

[0053] 3) Dimethyl-vinyl phosphate transesterification: add 40 g of amino starch modified surface-modified polyaluminum iron silicate prepared in step 2) into 130 g of acetone, then add 20 g of dimethyl-vinyl phosphate, NaOCH 3 7.5g and 8g of chloranil were reacted at 80°C for 11 hours, then filtered, washed with water for 5 times, then ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com