Preparation method of unpolished rice fermented raw solution for cosmetics and product of preparation method

A technology of cosmetics and brown rice, which is applied in the field of preparation of high-activity brown rice fermentation stock solution for cosmetics, can solve the problems of low extraction rate of active ingredients, high acidity, and difficulty in controlling the intermediate process, so as to shorten the fermentation cycle, improve fermentation efficiency, The effect of increased conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

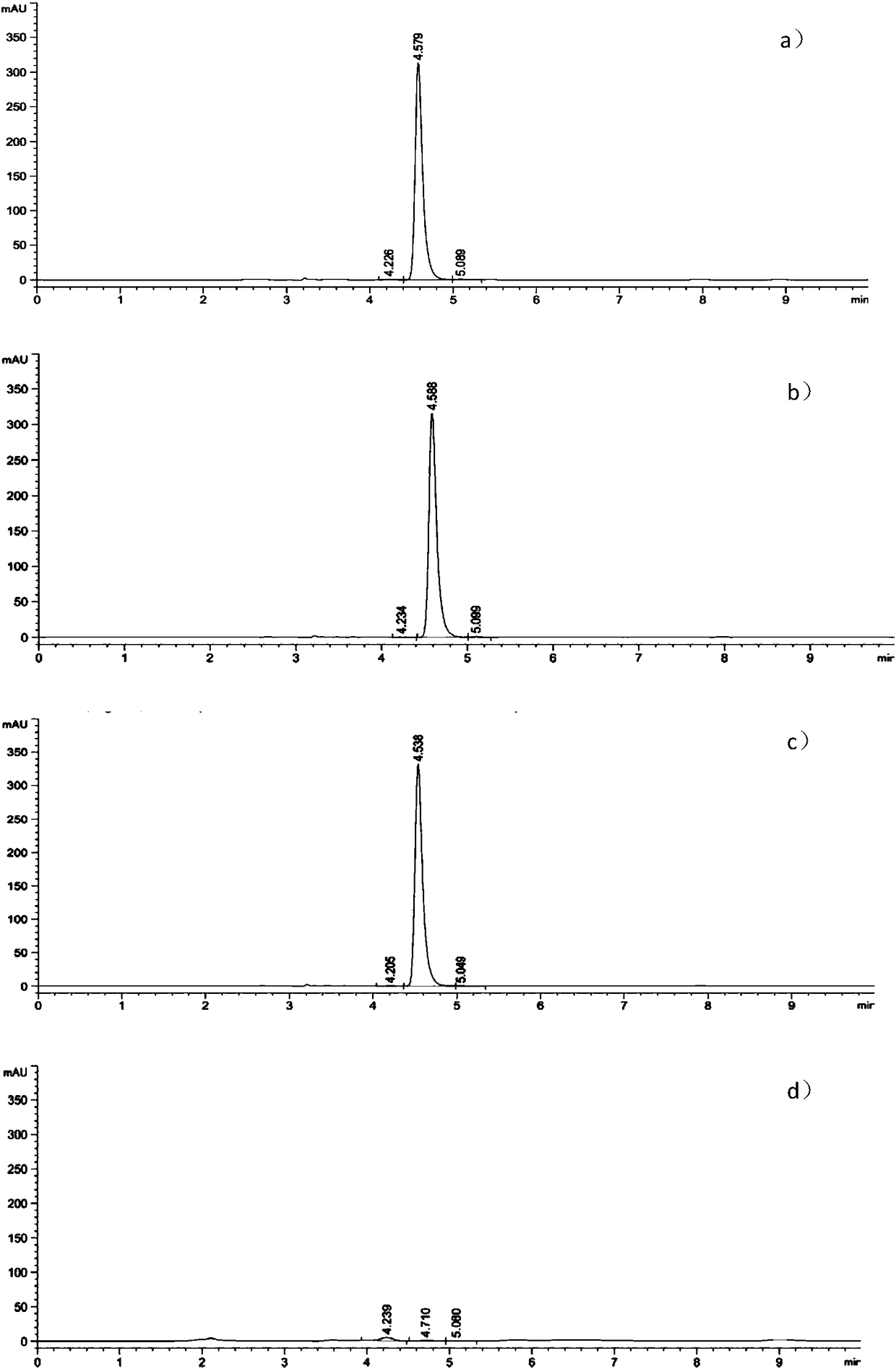

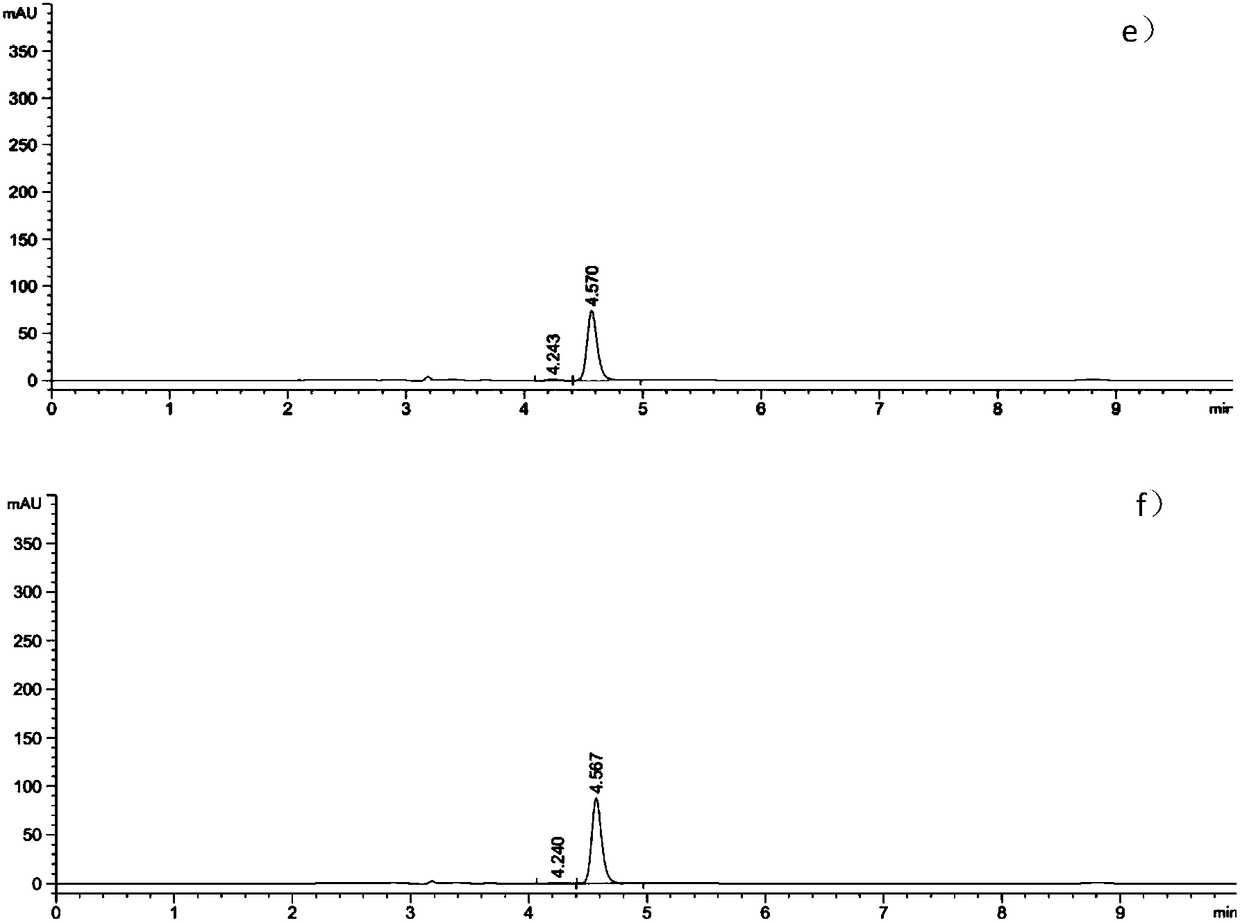

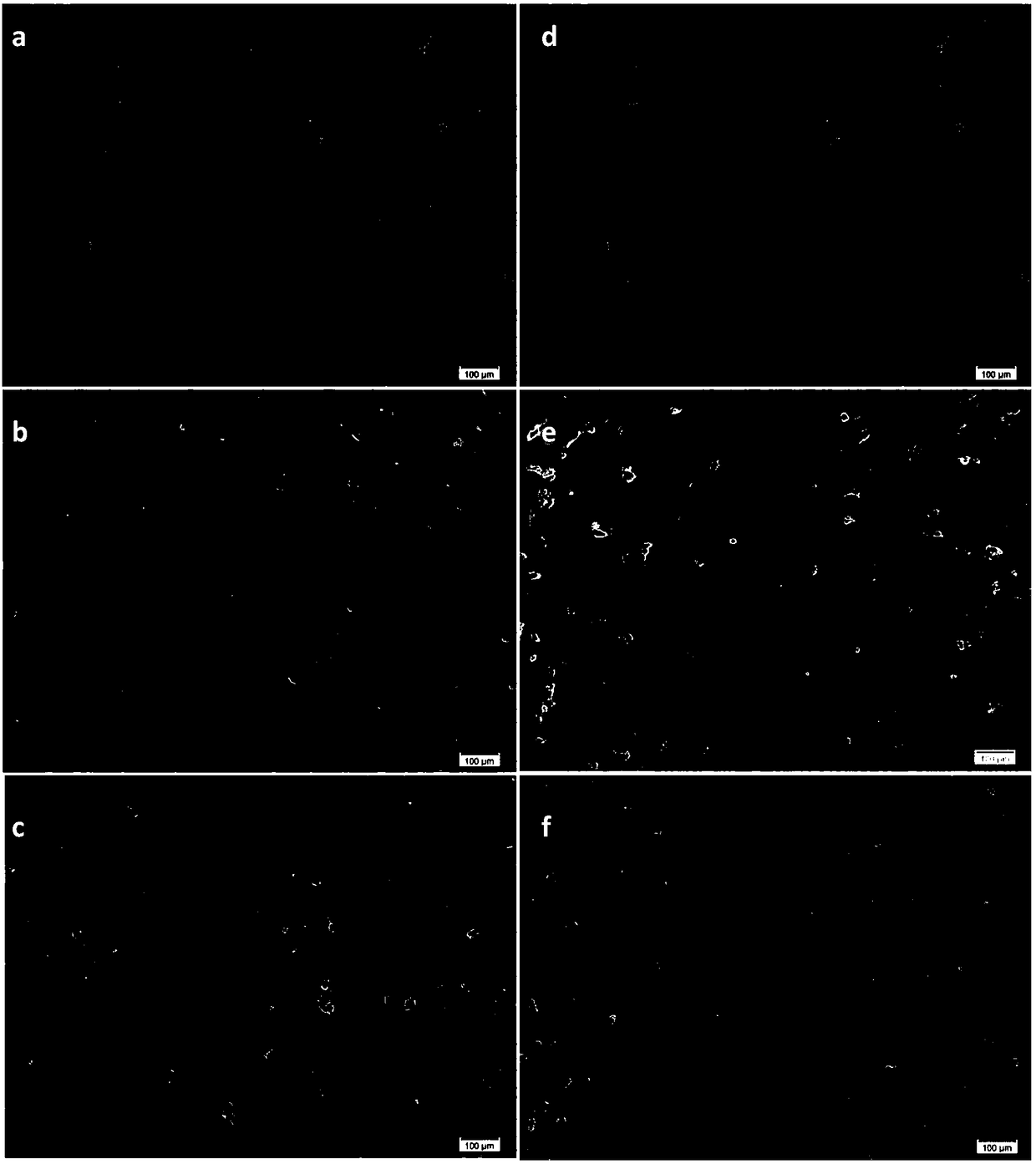

Image

Examples

Embodiment 1

[0047] Example 1 Preparation of Yeast Fresh Cells

[0048] Pick Hansenula spp. strains from the test tube and inoculate them in 500mL sterile seed culture solution containing 4-8%wt of glucose, 0.5-1%wt of peptone, and 0.1-0.5%wt of dipotassium hydrogen phosphate, and the shaking table rotates at 150rpm. After culturing at 30°C for 13 hours, when it reached the logarithmic growth phase, it was inoculated again and expanded into 5L seed medium. After the second culture for 10 hours, it reached the logarithmic phase, and was obtained by centrifuging at 10,000 rpm for 30 minutes and discarding the supernatant.

Embodiment 2

[0050] (1) Weigh 10kg of brown rice and soak it in 20kg of water for 24 hours, then dry it at 60°C for 10 hours, and grind it into brown rice flour with a moisture content of 5.2%;

[0051] (2) Take 8.5kg of brown rice flour in step (1) and add 100L of water to mix it into rice milk, then add 100mL of α-amylase solution and α-glucoamylase solution in total, enzymatically hydrolyze, measure the glucose content every 0.5h, until no longer When changing, the enzymatic hydrolyzate of rice milk was obtained, and its residual sugar content was 58.5g / L;

[0052] (3) Add 5g / L bean cake powder to the above rice milk enzymatic hydrolysis solution as a nitrogen source, 1g / L dipotassium hydrogen phosphate as a culture medium, insert the yeast cells in Example 1, and add 1g biotin at the same time , add 55g of glutamic acid powder in the middle to keep the pH between 5.0-5.5, ferment at 30°C for 20 hours, after there is no residual sugar, the fermentation ends, and the fermentation liquid ...

Embodiment 3

[0055] (1) Weigh 3kg of brown rice and immerse it in 4.5kg of water for 18 hours, then dry it at 80°C for 5 hours, and grind it into brown rice flour with a moisture content of 6.2%;

[0056] (2) Take 2.2kg of brown rice flour in step (1) and add 30L of water to mix it into rice milk, then add 25ml of α-amylase solution α-glucoamylase solution, enzymatically hydrolyze, measure the glucose content every 0.5h, until no change , the rice milk enzymatic hydrolyzate was obtained, and its residual sugar content was 63.1g / L;

[0057] (3) Add 5g / L yeast powder to the above-mentioned rice milk enzymolysis solution as a nitrogen source, 1g / L dipotassium hydrogen phosphate as a culture medium, insert the yeast cells in Example 1, and add 0.3g tobacco Add 15g of glutamic acid powder in the middle to keep the pH between 5.0-5.5, and ferment at 32°C for 16 hours. After no residual sugar, the fermentation ends and the fermentation liquid is obtained;

[0058] (4) The fermentation broth was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com