Device and method for recycling and reusing phosphorus-containing flue gas in yellow phosphorus storage tank

A technology for flue gas recovery and yellow phosphorus storage, applied in the field of phosphorus chemical technology and environmental protection, can solve the problems of unstable chemical properties of hypochlorous acid, increase additional costs, easy decomposition, failure, etc., to save power equipment and costs, The effect of reducing power equipment and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

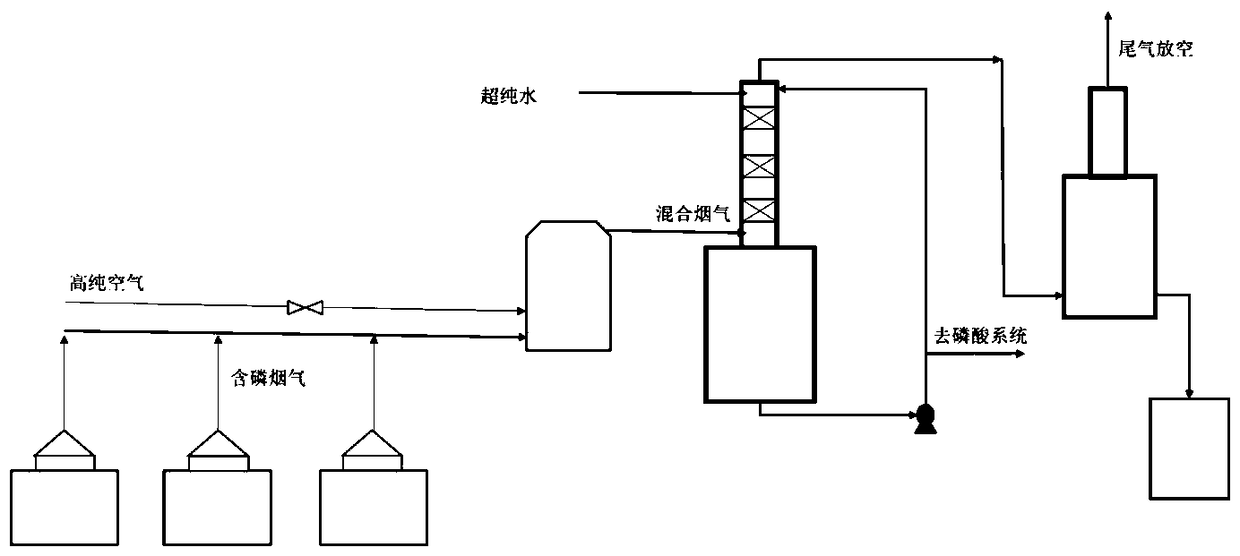

[0041] A device and method for recycling phosphorus-containing flue gas from a yellow phosphorus storage tank. The three-stage yellow phosphorus storage tank is connected to a buffer tank through a gas collector, the buffer tank is connected to a spray tower through a manual valve, and the top of the spray tower is connected to a pipeline. It is connected with the electrostatic demister, and the bottom of the electrostatic demister is connected to the dilute acid tank. The upper part of the spray tower is equipped with an absorbent inlet pipeline, and the flow is controlled by the first solenoid valve to enter from the sprinkler; the bottom of the spray tower is connected to the circulating acid pump through a pipeline, and then connected to the top of the spray tower to form a circulation pipeline. The outlet pipeline of the circulating acid pump is equipped with a phosphoric acid production pipeline; the inside of the spray tower is equipped with a phosphoric acid concentrati...

Embodiment 2

[0058] A device for recovering and reusing phosphorus-containing flue gas from a yellow phosphorus storage tank is the same as in Example 1.

[0059] A method for recycling phosphorus flue gas of the present embodiment selects the above-mentioned phosphorus flue gas recycling device, and connects the exhaust pipes of the yellow phosphorus A, B, and C pits with a flue gas collector, including the following steps:

[0060] (1) Set the upper limit of the liquid level of the spray tower to 40% and the concentration of phosphoric acid in the aqueous solution in the spray tower to 40% through the controller;

[0061] (2) The controller opens the valve on the absorbent delivery pipe, passes the absorbent into the sprayer, and evenly sprays the absorbent with the formula of 25% (mass fraction) hydrogen peroxide, 5% inorganic acid, and 70% water into the tower;

[0062] (3) Manually open the outlet valve of the buffer tank, so that the phosphorus-containing flue gas enters the spray t...

Embodiment 3

[0068] A device for recovering and reusing phosphorus-containing flue gas from a yellow phosphorus storage tank is the same as in Example 1.

[0069] A method for recycling phosphorus flue gas of the present embodiment selects the above-mentioned phosphorus flue gas recycling device, and connects the exhaust pipes of the yellow phosphorus A, B, and C pits with a flue gas collector, including the following steps:

[0070] (1) Set the upper limit of the liquid level of the spray tower to 45% and the concentration of phosphoric acid in the aqueous solution in the spray tower to 40% through the controller;

[0071] (2) The controller opens the valve on the absorbent delivery pipe, passes the absorbent into the sprayer, and evenly sprays the absorbent with the formula of 25% (mass fraction) hydrogen peroxide, 5% inorganic acid, and 70% water into the tower;

[0072] (3) Manually open the outlet valve of the buffer tank, so that the phosphorus-containing flue gas enters the spray t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com