Black zirconium oxide ceramic and preparation method thereof

A technology of black zirconia and ceramics, applied in the field of ceramics, can solve problems such as uneven color of black ceramics, decline in mechanical properties of black ceramics, and limited development level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing black zirconia ceramics, comprising the following steps:

[0034] (1) Sanding the mixed slurry comprising oxide, dispersant and water to obtain sanding slurry;

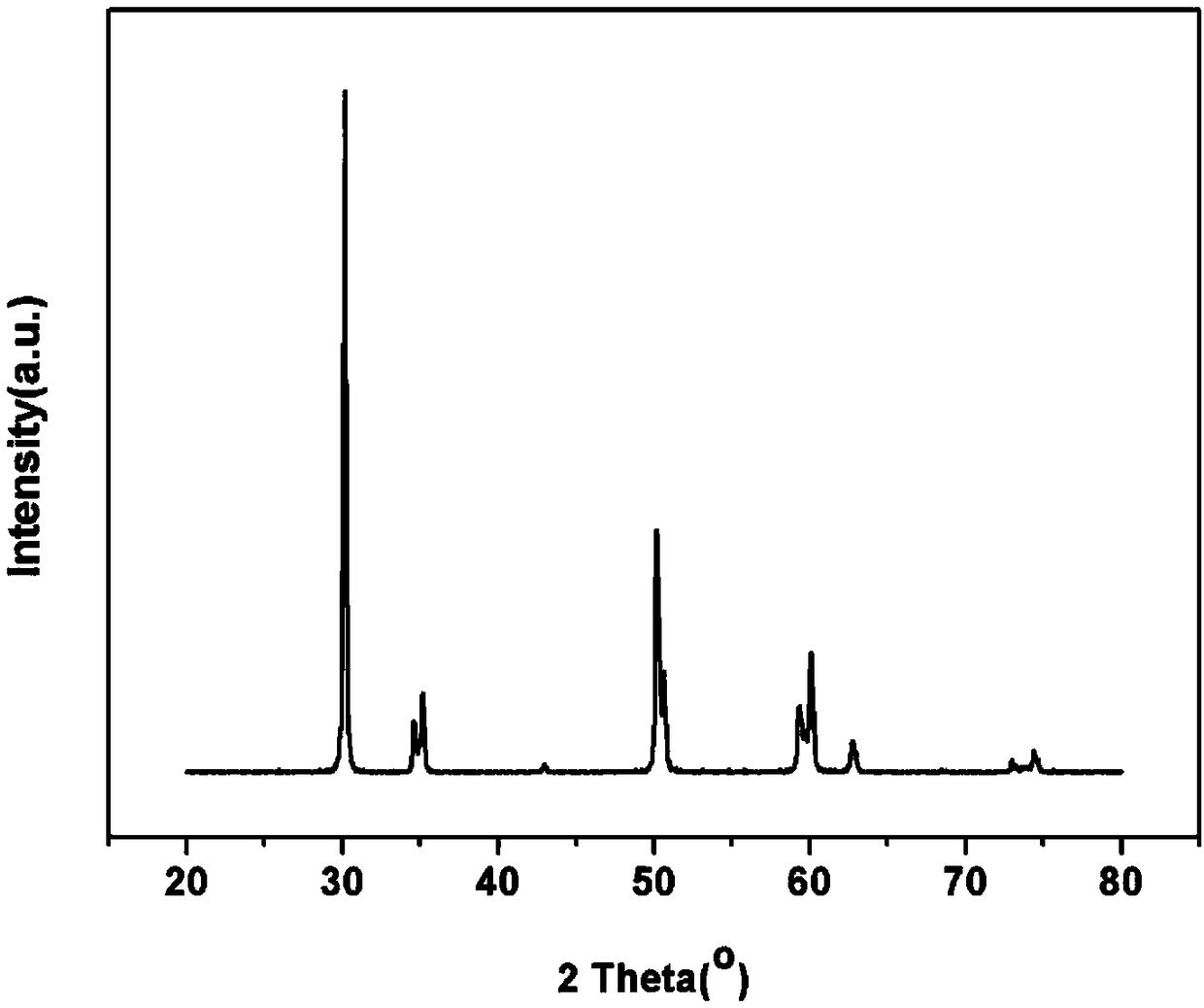

[0035] The mass ratio of zirconia, yttrium trioxide, titanium oxide and aluminum oxide in the oxide is (847-940): (48-54): (5-100): (1-5);

[0036] (2) mixing the sand grinding slurry obtained in the step (1) with a binder, followed by granulation, molding, debinding and sintering to obtain primary ceramics;

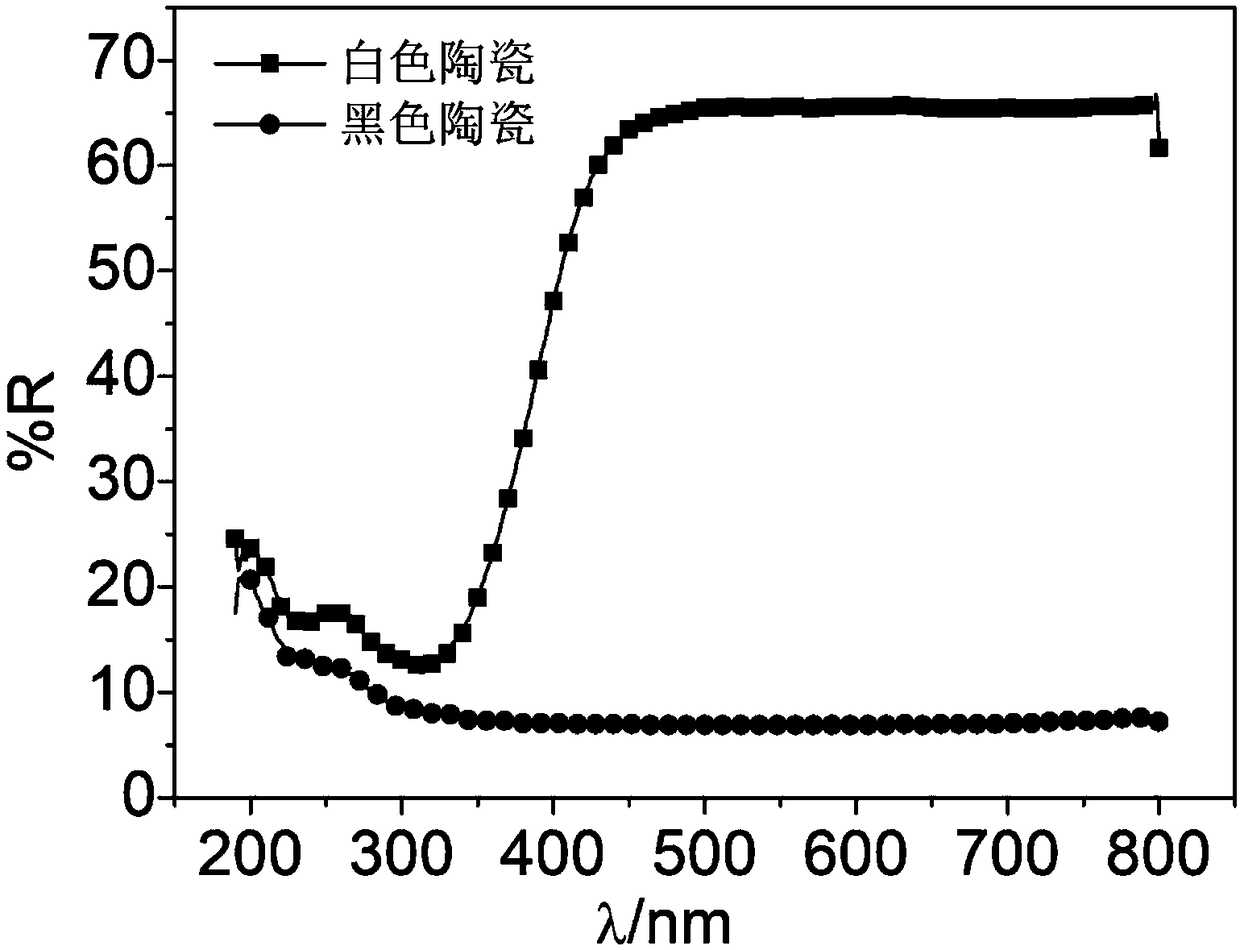

[0037] (3) performing a reduction reaction on the primary ceramics obtained in the step (2) to obtain black zirconia ceramics; the temperature of the reduction reaction is 1350-1550°C.

[0038] In the present invention, unless otherwise specified, the raw materials used in the preparation method are commercially available products well known to those skilled in the art.

[0039] The invention performs sanding treatment on the mixed slurry containing oxide, d...

Embodiment 1

[0057] Based on the total mass of zirconia, yttrium trioxide, titanium oxide, and aluminum oxide as 1000 parts, accurately weigh 847 parts of zirconia, 48 parts of yttrium oxide, 100 parts of titanium oxide and 100 parts of aluminum oxide. 5 parts, dispersant ammonium methacrylate is 2.5 parts, add deionized water, adjust the solid content of the slurry to 50%, and grind the material through a sand mill for 2 hours, and the grinding body is zirconia with a particle size of 0.6-0.8mm Beads, the sanding speed is 1500r / min;

[0058] Add 0.3% of the total solid mass of polyvinyl alcohol binder to the slurry after sanding for spray granulation, adjust the atomization frequency to 46Hz, the air inlet temperature is 250°C, and the air outlet temperature is 95°C to obtain a particle size of 80 micron ceramic powder;

[0059] The ceramic granulation powder is pressed into the required ceramic body through the dry pressing process, and the ceramic product is fired at high temperature a...

Embodiment 2

[0063] Based on the total mass of zirconia, yttrium trioxide, titanium oxide, and aluminum oxide as 1000 parts, accurately weigh 866 parts of zirconia, 50 parts of yttrium trioxide, 80 parts of titanium oxide, and 4 parts of aluminum oxide. 3 parts, the dispersant ammonium polyacrylate is 3 parts, add deionized water, adjust the solid content of the slurry to 50%, and grind the material through a sand mill for 3 hours. The grinding speed is 1600r / min;

[0064] Add 0.6% of the total solid mass of polyvinyl alcohol binder to the slurry after sanding for spray granulation, adjust the atomization frequency to 38Hz, the air inlet temperature to 240°C, and the air outlet temperature to 95°C to obtain a particle size of 90 micron ceramic powder;

[0065] The ceramic granulation powder is pressed into the required ceramic body through the dry pressing process, and the ceramic product is fired at high temperature after the debinding process. The sintering temperature is 1500°C and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com